Industrialized production technology of ecological spawns

A production technology, a factory-based technology, applied in horticulture, botany equipment and methods, plant cultivation, etc., can solve problems such as shortage of raw materials, achieve factory-like mass production, good application prospects, and solve the effect of raw material shortage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

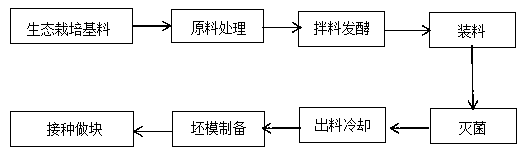

Image

Examples

Embodiment 1

[0021] (1) The raw materials of the ecological cultivation base material are calculated in parts by weight: 68-70 parts of Hongsen pagoda tree sawdust, 20-25 parts of bran, 6 parts of rice bran, 13 parts of cotton seed hulls, 15 parts of crop straw, 1-3 parts of urea, 1-3 parts of phosphate fertilizer, 6 parts of manure, 0.2 parts of three-dimensional nutrients of edible fungi, 1-3 parts of gypsum, and 1-3 parts of lime.

[0022] (2) Raw material processing: Hongsen pagoda tree sawdust is crushed to a size of 0.8cm×0.8cm×0.3cm, cottonseed hulls and crop straw are mixed and crushed to 100-150 mesh, bran and rice bran are crushed to 200-300 mesh respectively, manure is dried in the sun Dry.

[0023] (2) Stirring fermentation: Weigh the ingredients except the three-dimensional nutrient of edible fungus, gypsum and lime according to the weight of the formula, mix them, add water and stir evenly, adjust the moisture content to 60-70%, and then carry out stacking fermentation for 20...

Embodiment 2

[0030] (1) The raw materials of the ecological cultivation base material are calculated in parts by weight: 60-75 parts of Hongsen pagoda tree chips, 23-25 parts of bran, 4 parts of rice bran, 13 parts of cottonseed hulls, 15 parts of crop straw, 1-3 parts of urea, 1-3 parts of phosphate fertilizer, 6 parts of manure, 0.2 parts of three-dimensional nutrients of edible fungi, 1-3 parts of gypsum, and 1-3 parts of lime.

[0031] (2) Raw material processing: Hongsen pagoda tree sawdust is crushed to a size of 0.8cm×0.8cm×0.3cm, cottonseed hulls and crop straw are mixed and crushed to 100-150 mesh, bran and rice bran are crushed to 200-300 mesh respectively, manure is dried in the sun Dry.

[0032] (2) Stirring fermentation: Weigh the ingredients except the three-dimensional nutrient of edible fungus, gypsum and lime according to the weight of the formula, mix them, add water and stir evenly, adjust the moisture content to 60-70%, and then carry out stacking fermentation for 20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com