Environmentally-friendly and efficient chemical waste gas purification treatment device

A technology of exhaust gas purification and treatment device, applied in the field of mechanical processing, can solve the problems such as the inability to meet the needs of complex exhaust gas purification, the inability to process multiple mixed gases, and the single purification structure, so as to improve efficiency and quality, improve purification quality, and avoid The effect of putting into use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

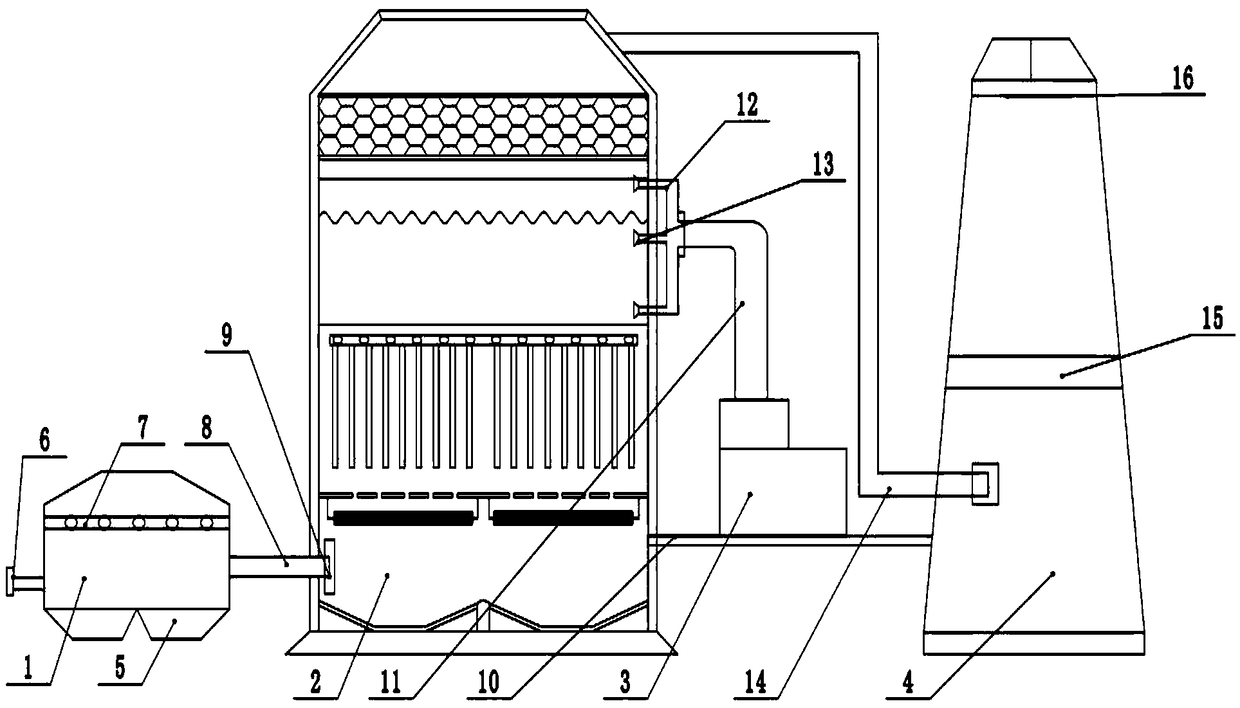

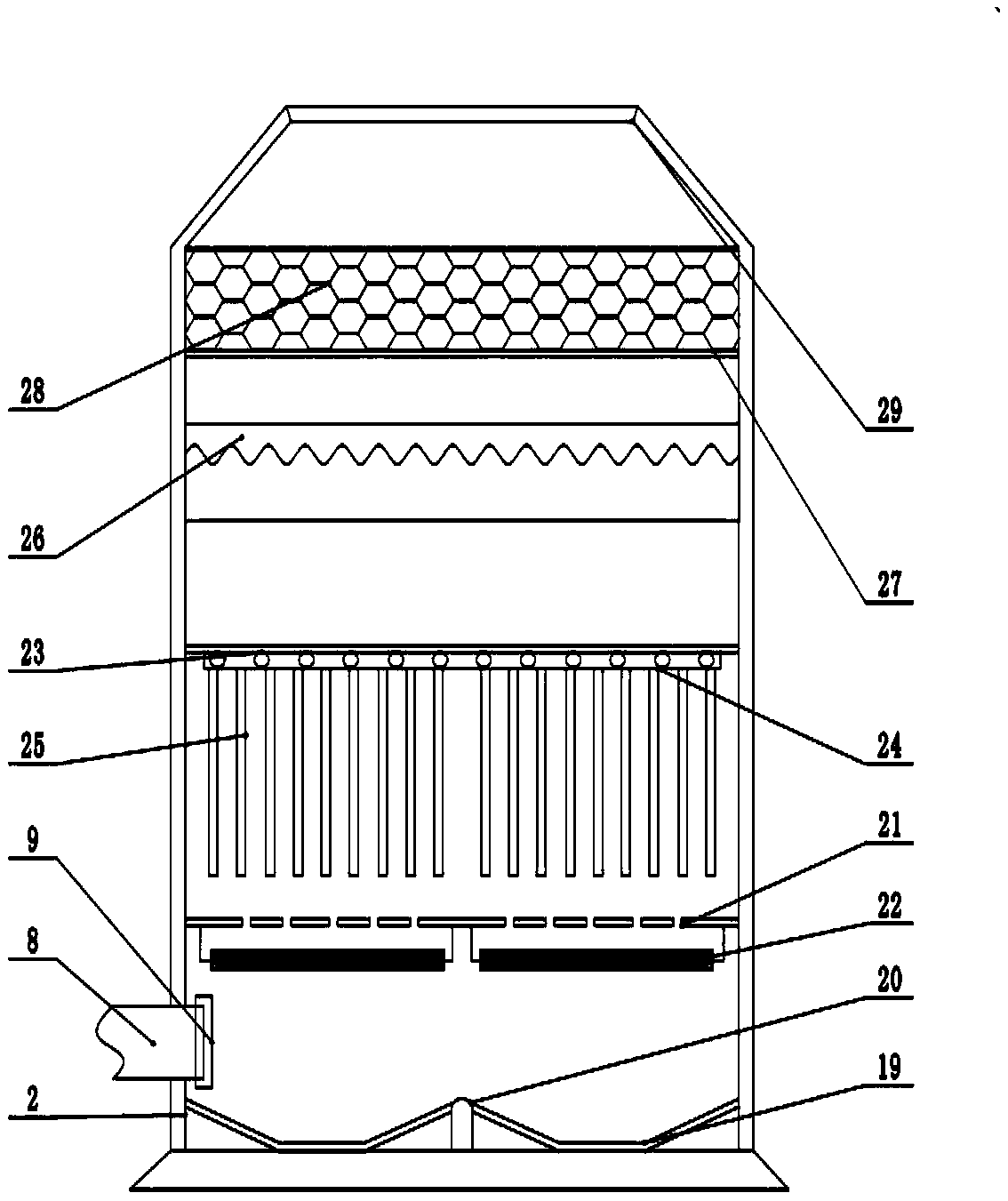

[0021] see figure 1 , an environmentally friendly and efficient chemical waste gas purification treatment device, including: electrostatic dust removal part 1, dust collection part 5, waste gas inlet 6, integrated purification tower 2, water tank 3, water pipeline 11, atomizing nozzle 13, the second The gas pipeline 14 and the exhaust gas purification tower 4, the electrostatic precipitator 1 uses electrostatic precipitator technology to perform the first step of dust removal on the exhaust gas, the left side of the electrostatic precipitator 1 is connected to the exhaust gas inlet 6, and the exhaust gas inlet 6 Connected to the external exhaust gas discharge device, the upper part of the electrostatic precipitator 1 is provided with an electrostatic generator 7, which ionizes the air through high-voltage electricity, and attaches and shoots down the particle dust in the air through negative ions. The lower part of the electrostatic precipitator 1 is fixed and installed There ...

Embodiment 2

[0024] Further, the interior of the purification plate 25 is filled with a chemical purifier, and different purifiers are reasonably selected according to the types of gases to be purified. There are several air inlets at both ends of the outer side of the purification plate 25, and exhaust gas enters through the air inlets and generates The reaction is discharged to the top of the purification plate support 23 by the gas channel 24 after purification.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com