Pressure energy recovery method by liquefied natural gas plant

A technology of liquefied natural gas and a recovery method, which is applied in the field of pressure energy recovery of liquefied natural gas devices, can solve the problems of large number of equipment, long process flow and high engineering investment, and achieves the effects of saving electricity costs, simple mechanical structure and good technical effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Taking an LNG liquefied natural gas plant with a processing capacity of 10,000 standard cubic meters per hour as an example, a method for recovering pressure energy of a liquefied natural gas plant according to the present invention is adopted, and the composition of raw natural gas is shown in Table 2.

[0024] Table 2. List of composition of raw natural gas

[0025] component name

total

Yield / mol%

93.25

1.08

0.01

5.14

0.01

0.51

100.00

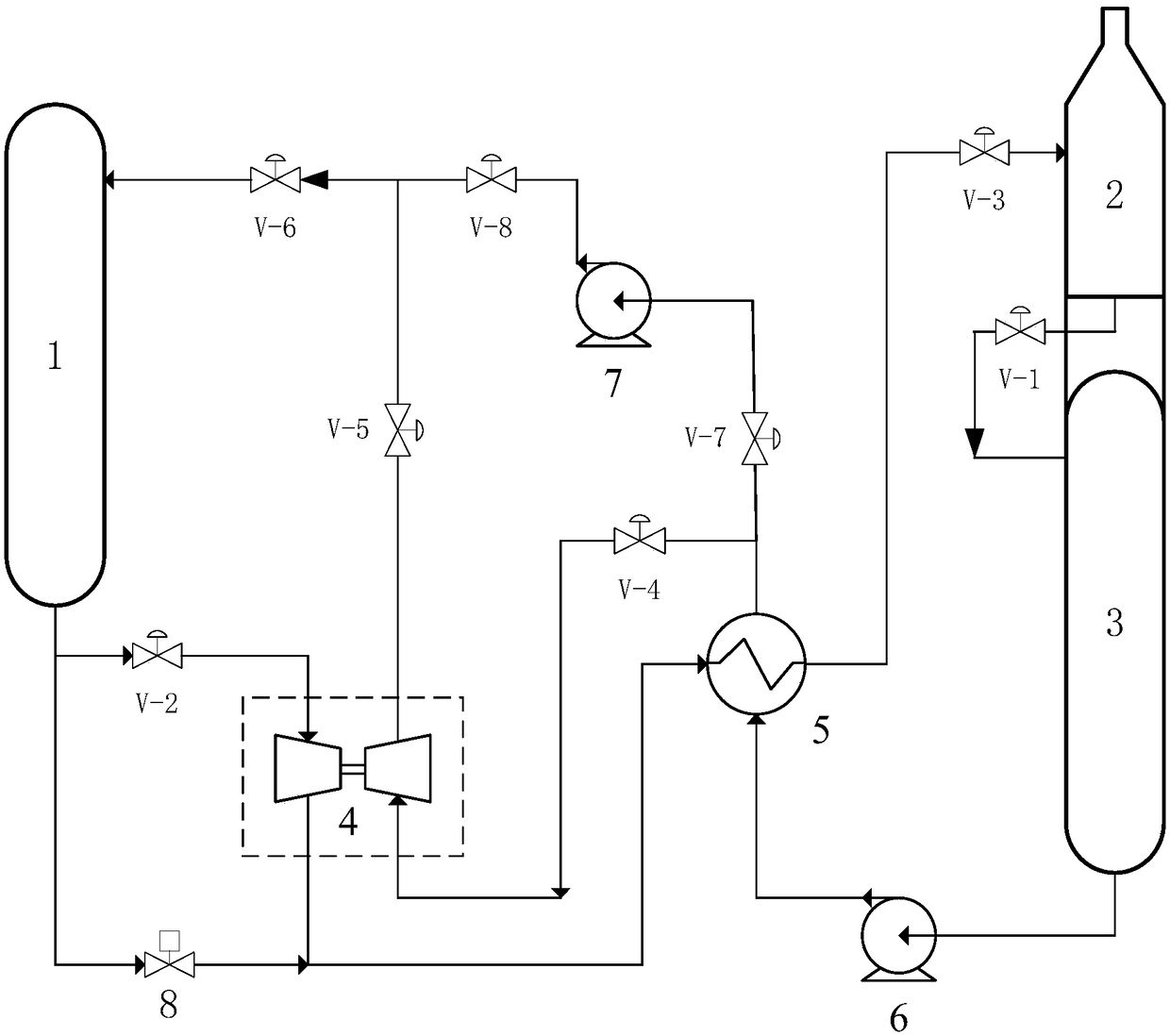

[0026] Such as figure 1 As shown, the process flow is as follows: the high-pressure lean liquid enters the acidic impurity absorption tower 1 to absorb the acidic impurities hydrogen sulfide H2S and carbon dioxide CO2 in the raw methane gas to form a high-pressure rich liquid, and the high-pressure rich liquid enters the online pressure recovery device 4 and is separated from the rich liquid de...

Embodiment 2

[0029] Same as [Example 1], the process operation parameters remain unchanged, only the processing capacity is expanded to 100,000 standard cubic meters per hour LNG liquefied natural gas plant, and the raw material natural gas composition is changed, as shown in Table 3.

[0030] Table 3. List of composition of raw natural gas

[0031] component name

[0032] Due to the adoption of the pressure energy recovery method of the liquefied natural gas plant of the present invention, in the process of removing the acidic impurities hydrogen sulfide H2S and carbon dioxide CO2 in the methane gas, the energy conversion efficiency of the online pressure recovery device 4 is 82.32%, and the energy recovery of the absorption-desorption system of the liquefied natural gas plant The efficiency is 61.82%, and the electricity cost is saved by 167,800 yuan / year. Other technical effects and economic benefits are shown in Table 6. After that, the methane gas is further condensed and li...

Embodiment 3

[0034] Same as [Example 1], the process operation parameters remain unchanged, and the composition of raw natural gas remains unchanged, only the processing capacity is expanded to 500,000 standard cubic meters per hour LNG liquefied natural gas plant. Due to the adoption of the pressure energy recovery method of the liquefied natural gas plant of the present invention, in the process of removing the acidic impurities hydrogen sulfide H2S and carbon dioxide CO2 in the methane gas, the energy conversion efficiency of the online pressure recovery device 4 is 84.98%, and the energy recovery of the absorption-desorption system of the liquefied natural gas plant The efficiency is 63.08%, and the electricity cost is saved by 809,500 yuan / year. Other technical effects and economic benefits are shown in Table 6. After that, the methane gas is further condensed and liquefied to meet the quality standards required by the process, and liquefied natural gas (LNG) products are produced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com