A method for assisting brazing of a graphene sponge intermediate layer

A technology of graphene sponge and intermediate layer, which is applied in welding equipment, welding medium, welding/cutting medium/material, etc., can solve the problems of large residual stress and low reliability, achieve continuous reaction layer, improve mechanical properties, reduce The effect of joint stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

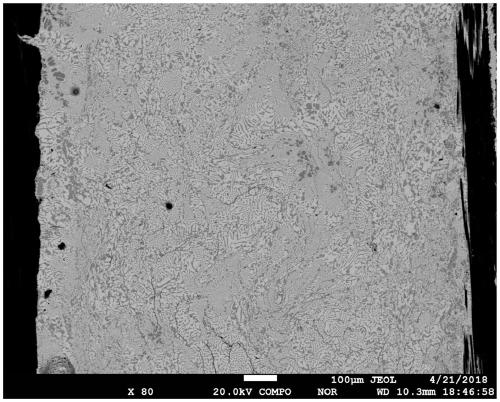

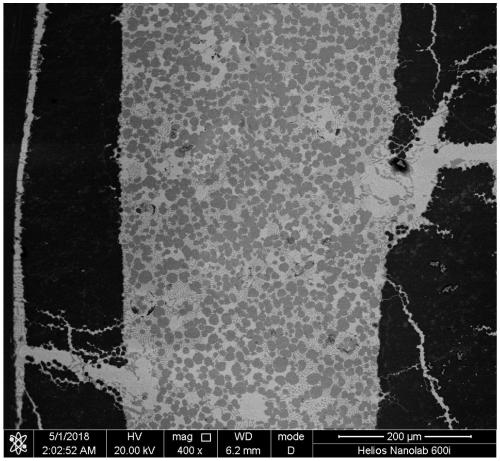

Image

Examples

specific Embodiment approach 1

[0022] Specific embodiment one: present embodiment a kind of method for auxiliary brazing of graphene sponge intermediate layer, specifically carry out according to the following steps:

[0023] 1. Cut the C / C composite material into thin slices with a thickness of 2-3 mm, then polish the parts to be welded with sandpaper, and then put them into acetone solution for ultrasonic cleaning to obtain the C / C composite material to be welded;

[0024] 2. Cut the graphene sponge into thin slices along the direction parallel to the cross section to obtain the middle layer of the graphene sponge;

[0025] 3. At room temperature, the AgCuTi powder brazing filler metal is subjected to sheeting treatment to obtain a button-shaped brazing filler metal sheet with a diameter of 8-12 mm;

[0026] Four, the graphene sponge intermediate layer that step 2 obtains and the solder sheet that step 3 obtains are stacked between two C / C composite materials to be welded that step 1 obtains and assemble,...

specific Embodiment approach 2

[0028] Embodiment 2: This embodiment is different from Embodiment 1 in that: In step 1, a wire electric discharge machine is used to cut the C / C composite material. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0029] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that in step one, 240#, 600# and 1000# sandpapers are used successively to polish the parts to be welded. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com