Compound elastomer film with heat-insulating property and preparation method

An elastomer and composite technology, which is applied in the field of composite elastomer film and preparation, can solve the problems of no near-infrared absorption function, no absorption of solar radiation, etc., and achieve good product performance, uniform and stable performance, and good bonding performance The effect of matching performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

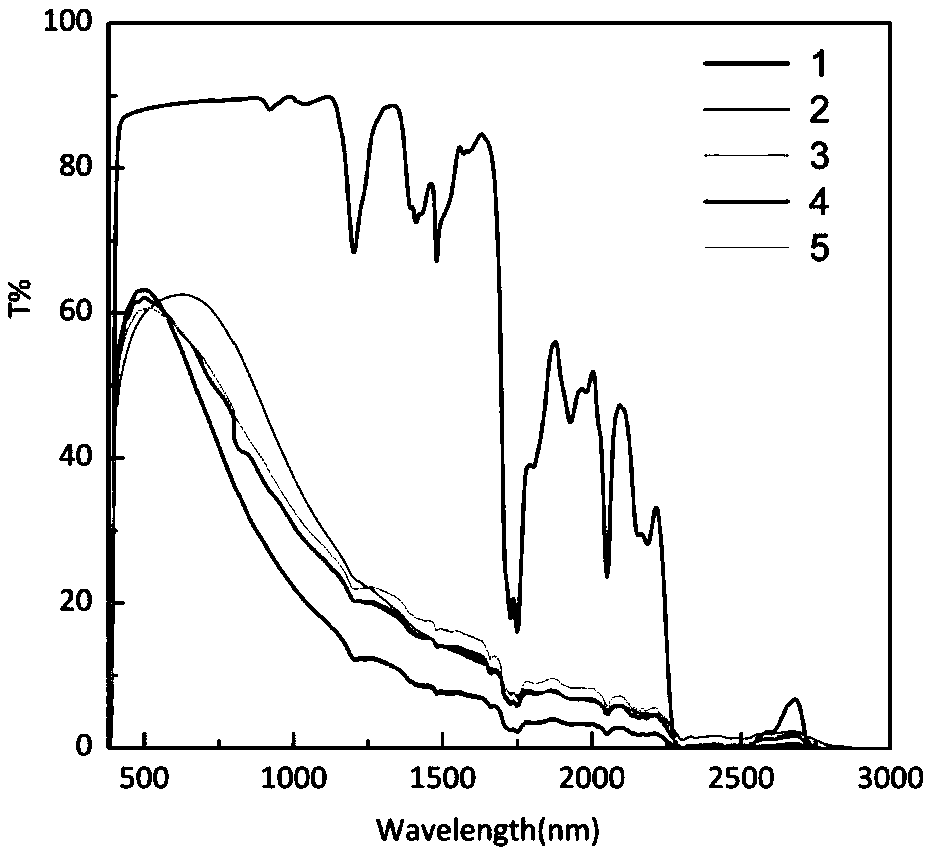

[0031] Two layers of TPU films with a thickness of 0.76mm were directly bonded and laminated by rolling to test their near-infrared barrier properties. In order to accurately test its visible light, near-infrared light transmittance and thermal conductivity, its surface is calendered.

Embodiment 2

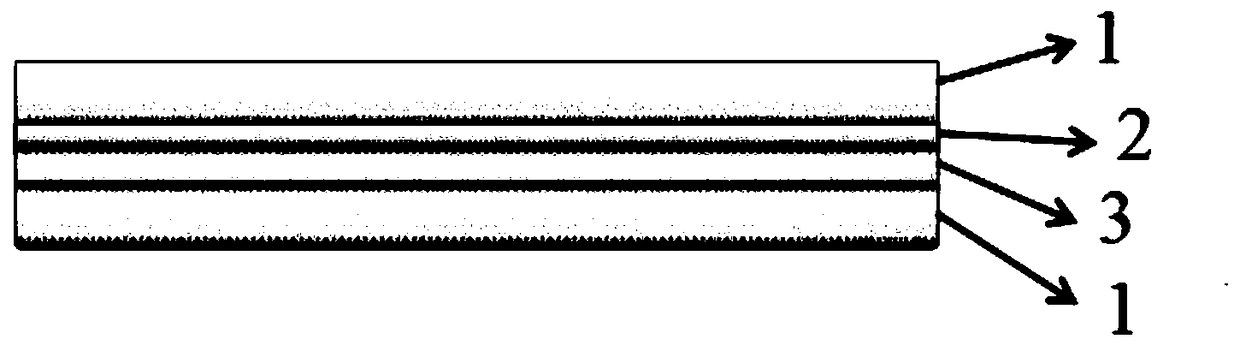

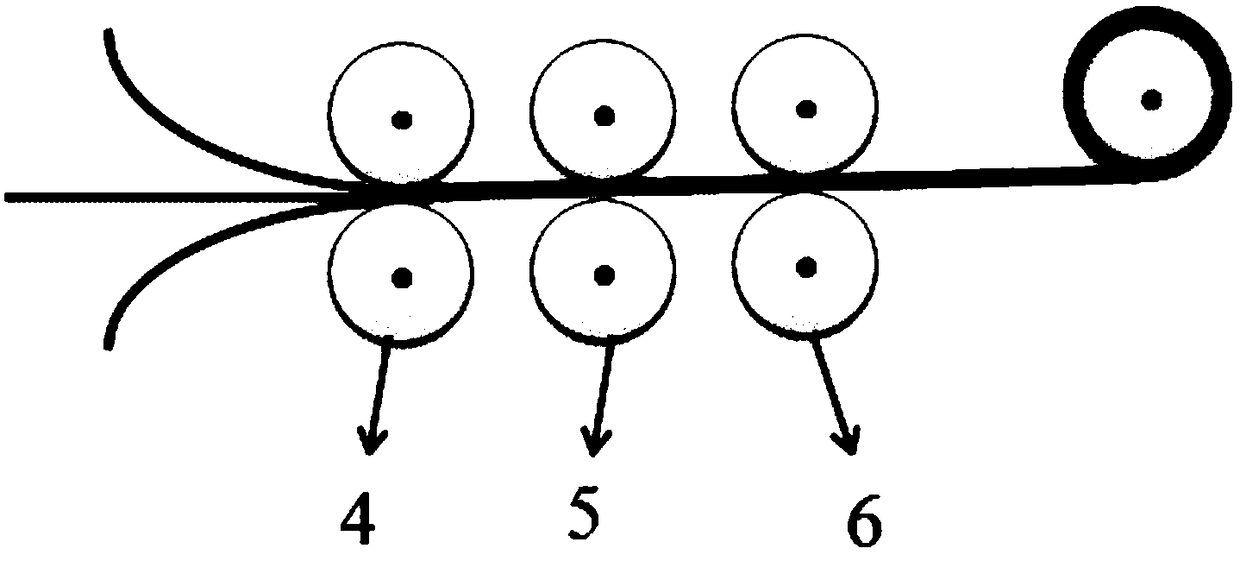

[0033] Sequential deposition of 10 nm thick SiO on PET with a thickness of 150 μm by roll-to-roll magnetron sputtering 2 Film, 45nm thick ITO film, 9nm thick Ag film, 40nm thick ITO film, get PET film with near-infrared reflection function. The functional PET film is bonded to two layers of TPU films with a thickness of 0.76 mm by double-roll calendering. A composite elastomer film with thermal insulation function is obtained. The film obtained from the embossing roll needs to be calendered in order to accurately measure its visible light, near-infrared transmittance and thermal conductivity.

Embodiment 3

[0035] With reference to the method of embodiment 2, change the thickness of the Ag film on the PET surface, be 11nm, adopt the same method as embodiment 2 to bond with two layers of TPU films; test its thermal conductivity and visible light, near-infrared transmittance after calendering light rate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com