Formula and preparation method of polyurethane glue, and multi-layer glass

A technology of polyurethane glue and formula, which is applied in polyurea/polyurethane adhesives, chemical instruments and methods, glass/slag layered products, etc., can solve the problem of many bubbles in the glued layer, and achieve strong adhesion and environmental resistance good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

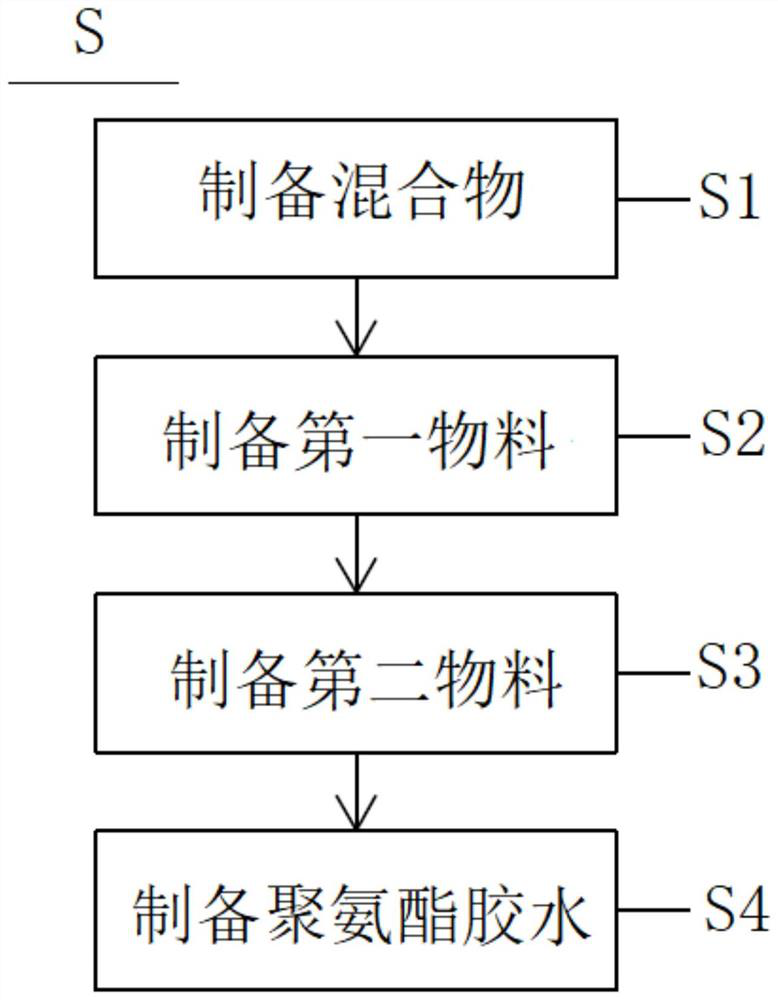

[0020] In order to make the purpose, technical solution and advantages of the present application clearer, the implementation manners of the present application will be further described in detail below in conjunction with the accompanying drawings.

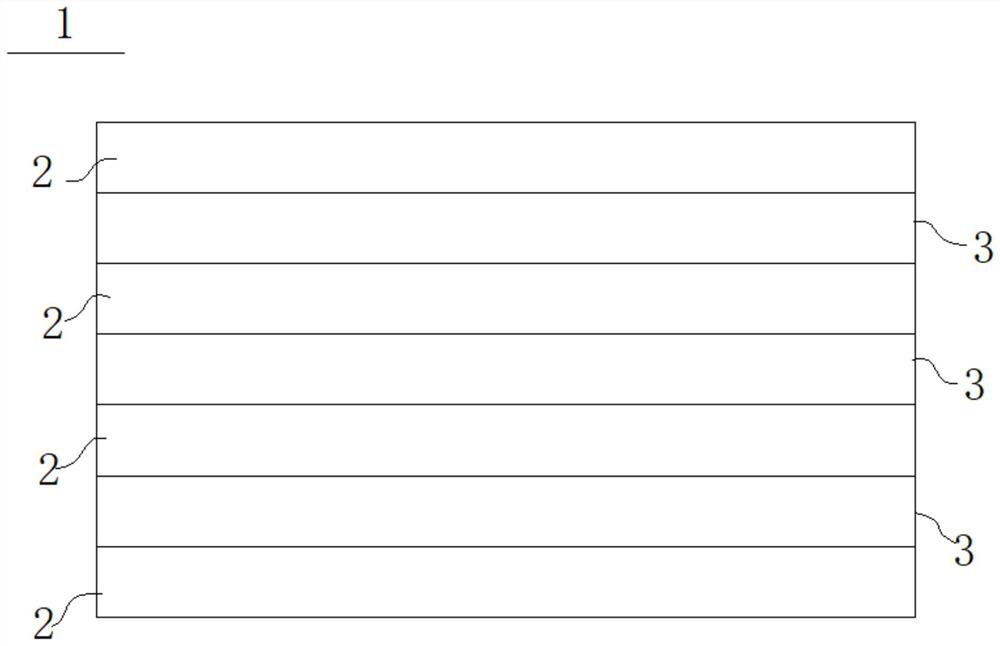

[0021] For multi-layer glass laminates, when the thickness of the laminated glass is large, the heat transfer in the middle area of the film used is slow, resulting in the unmelted middle area of the film, and the difficulty of venting the glued layer, resulting in more air bubbles. .

[0022] The polyurethane glue prepared by the formula of the polyurethane glue of the present application and the preparation method thereof has a small viscosity and is easy to operate. After lamination of multiple layers of glass, the adhesive layer is colorless and transparent, has strong adhesion and good environmental resistance, and solves the problem of large thickness. Glass lamination cannot use hot pressing.

[0023] The beneficial e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Adhesive strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com