Magnesium-based blue matt glaze

A matte glaze and blue technology, which is applied in the field of magnesium-based blue matte glaze and its preparation, can solve the problems of poor adaptability, high cost, and rough glaze surface of color glazes, and achieve the effect of improving coloring ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

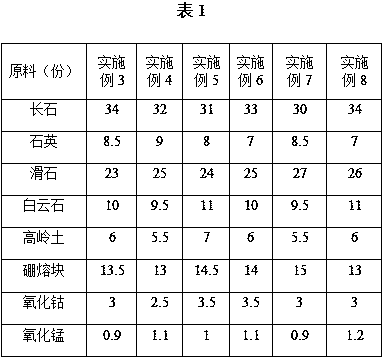

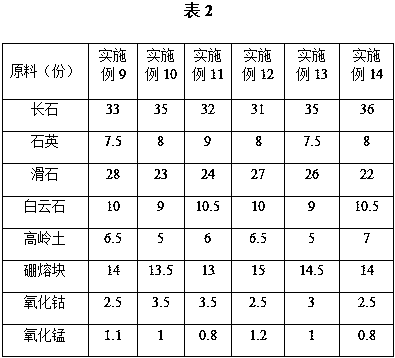

[0018] A magnesium-based blue matte glaze, which is composed of the following raw materials in parts by weight: feldspar 30-36, quartz 7-9, talc 22-28, dolomite 9-11, kaolin 5-7, boron frit 13- 15. Cobalt oxide 2.5-3.5, manganese oxide 0.8-1.2. Among them, feldspar, talc, dolomite and kaolin are taken from Yuzhou. The boron frit is purchased from domestic manufacturers, preferably with boron oxide content greater than 5%, calcium oxide greater than 7% and magnesium oxide greater than 1.5%; the main chemical composition content of the boron frit used in the present invention: silicon oxide 51.6%, aluminum oxide 11.8%, calcium oxide 7.8%, magnesium oxide 2.1%, boron oxide 8.7%, zinc oxide 4.6%, barium oxide 2.5%, potassium oxide 4.6%, sodium oxide 3%.

[0019] The preparation method of magnesium-based blue matte glaze as described above comprises the following steps:

[0020] (1) Mix the raw materials; ball mill to obtain the glaze slurry; pass the glaze slurry through a sieve...

Embodiment 2

[0026] A magnesium-based blue matte glaze is composed of the following raw materials in parts by weight: 33 parts by weight of feldspar, 8 parts of quartz, 25 parts of talc, 10 parts of dolomite, 6 parts of kaolin, 14 parts of boron frit, 3 parts of cobalt oxide and 1 part of manganese oxide.

[0027] The preparation method of magnesium-based blue matte glaze as described above comprises the following steps:

[0028] (1) Mix the raw materials; ball mill to obtain the glaze slurry; pass the glaze slurry through a sieve of more than 200 mesh;

[0029] (2) Glaze is applied to the carcass after bisque firing; the thickness of the glaze is 0.6-0.8mm;

[0030] (3) Firing: Firstly, the glazed carcass is uniformly raised to 1050°C in 4 hours in an oxidizing atmosphere; then in a reducing atmosphere, the temperature is evenly raised to 1300°C in 2.5 hours; kept for 40 minutes, and then cooled in 7 hours to room temperature.

[0031] The glaze color of the product prepared in this exa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com