Anti-condensation medical silica material modified by blending and cross-linking micron-sized hollow mesoporous SiO2 microspheres and PDMS

A micron-scale, mesopore technology, applied in the field of medical materials, can solve the problems of increasing the incidence of ventilator-associated pneumonia, tilting or inverting the temperature-controlled water collection cup, and prolonging the hospital stay of ICU patients, so as to improve the anti-fogging performance , Reduce the formation of condensed water in the pipeline and prevent the loss of gas temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

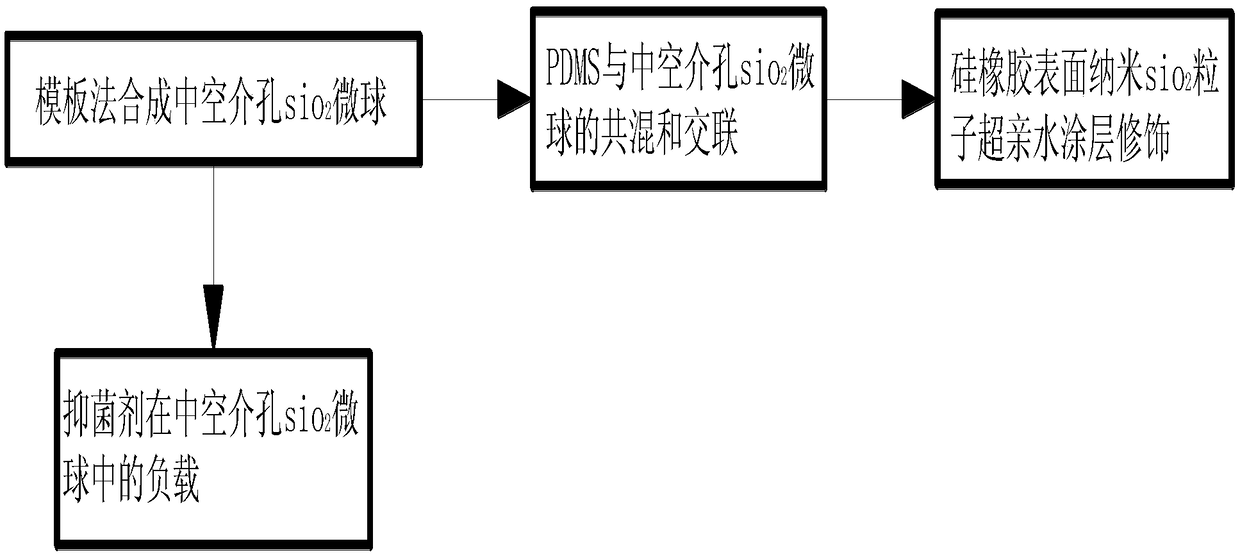

[0032] Such as Figure 1-5 As shown, a micron-scale hollow mesoporous SiO 2 The microsphere and PDMS blend cross-linking modified anti-coagulation water medical silica gel material, the preparation method comprises the following steps:

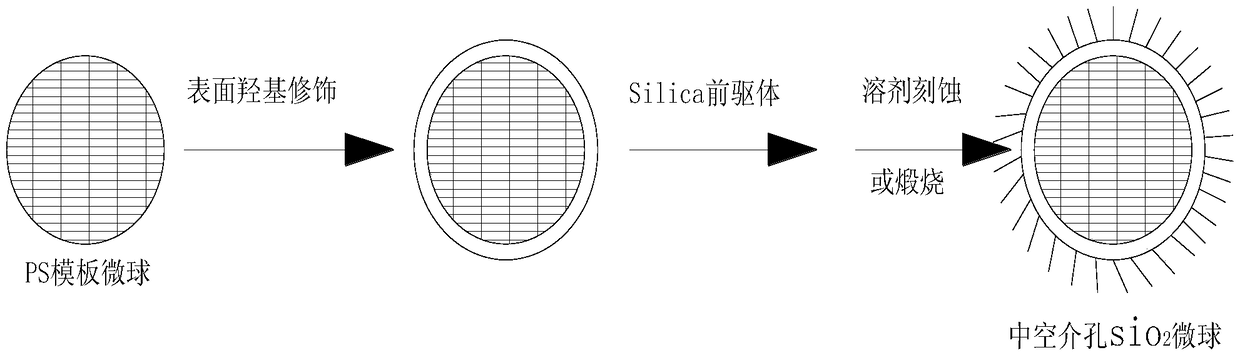

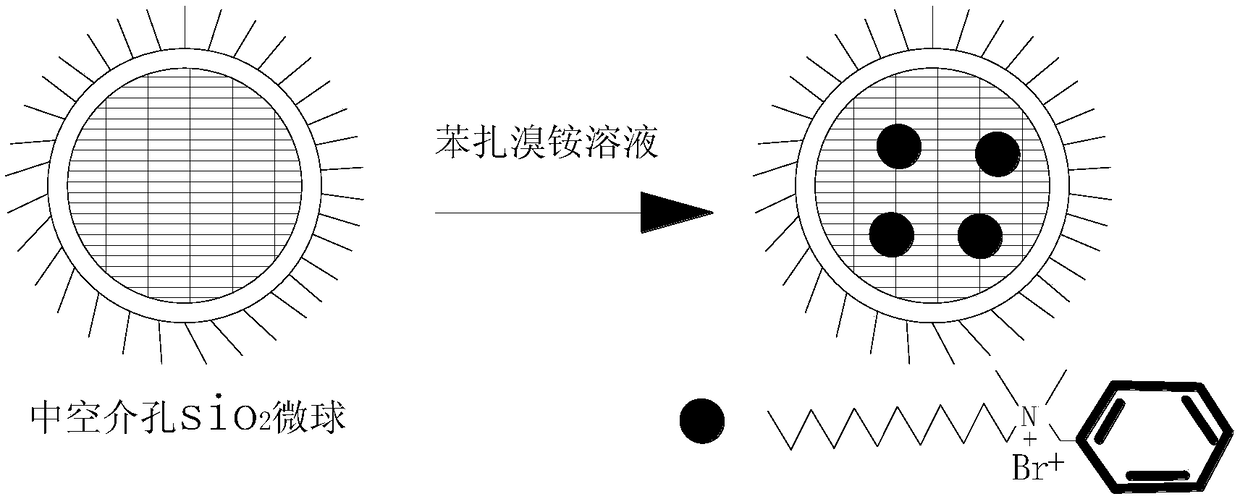

[0033] (1) Micron-scale hollow mesoporous SiO 2 Microsphere Synthesis:

[0034] i) Polystyrene microspheres were prepared by using a soap-free emulsion method. The initiator was water-soluble potassium persulfate. Under the protection of nitrogen, let the two react for 24 hours at a temperature of 70 ° C to obtain a monodisperse micron-sized polystyrene template. Microspheres;

[0035] ii) dispersing the polystyrene template microspheres in step i) in an aqueous ethanol solution containing a trace amount of tetraethylorthosilicate, adding dropwise an appropriate amount of ammonia water, reacting a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com