Hydrothermal quality-improvement, separation and purification method for unconventional petroleum containing water and sands

A technology of hydrothermal upgrading and purification method, which is applied in the petroleum industry, treatment of hydrocarbon oil, and multi-stage series-connected refining process treatment, etc. Conducive to removal, reduce energy consumption and environmental pollution, good mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

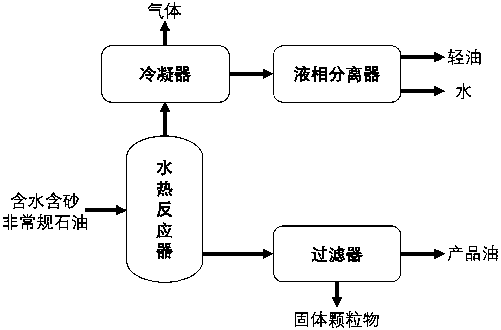

Image

Examples

Embodiment 1

[0023] A method for hydrothermal upgrading and separation and purification of unconventional petroleum containing water and sand, the steps are as follows:

[0024] (1) Add 2.5 kg of asphalt foam (containing 75 wt% asphalt oil, 19 wt% water and 6 wt% solid particles) into the stirred high-temperature and high-pressure reactor, and replace the air in the reactor with nitrogen for three times to ensure that the reaction process is Inert gas atmosphere. Set the temperature of the thermostat to 320 °C, turn on the heating furnace and stirrer (350 rpm), raise the temperature from room temperature to the set temperature and keep it for 30 minutes, then turn off the heating furnace.

[0025] (2) Turn on the condenser refrigeration unit, then open the gas discharge valve and discharge the gas in the reactor into the condenser. The uncondensed gas released from the end of the condenser is introduced into the fume hood, and the condensed liquid enters the separator and stands still for...

Embodiment 2

[0028] A method for hydrothermal upgrading and separation and purification of unconventional petroleum containing water and sand, the steps are as follows:

[0029] (1) Add 1.9 kg of oil sand oil (containing 97.2 wt% bitumen, 2 wt% water and 0.8 wt% solid particles) obtained by anhydrous extraction (using cyclohexane as solvent) and cyclo Hexane 0.19 kg, purging and replacing the air in the reactor with nitrogen three times to ensure that the reaction process is an inert gas atmosphere. Set the temperature of the thermostat to 360°C, turn on the heating furnace and stirrer (350 rpm), raise the temperature from room temperature to the set temperature and keep it for 30 minutes, then turn off the heating furnace.

[0030] (2) Open the condenser, open the gas discharge valve and discharge the gas in the reactor into the condenser. The uncondensed gas released from the end of the condenser is introduced into the fume hood, and the condensed liquid enters the separator and stands ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com