Painting-free light quick-assembly prefabricated wall system

A prefabricated wall, coating-free technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of waste of resources, long construction period, slow construction, etc., and achieve the effect of convenient transportation, good stability, and quick assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

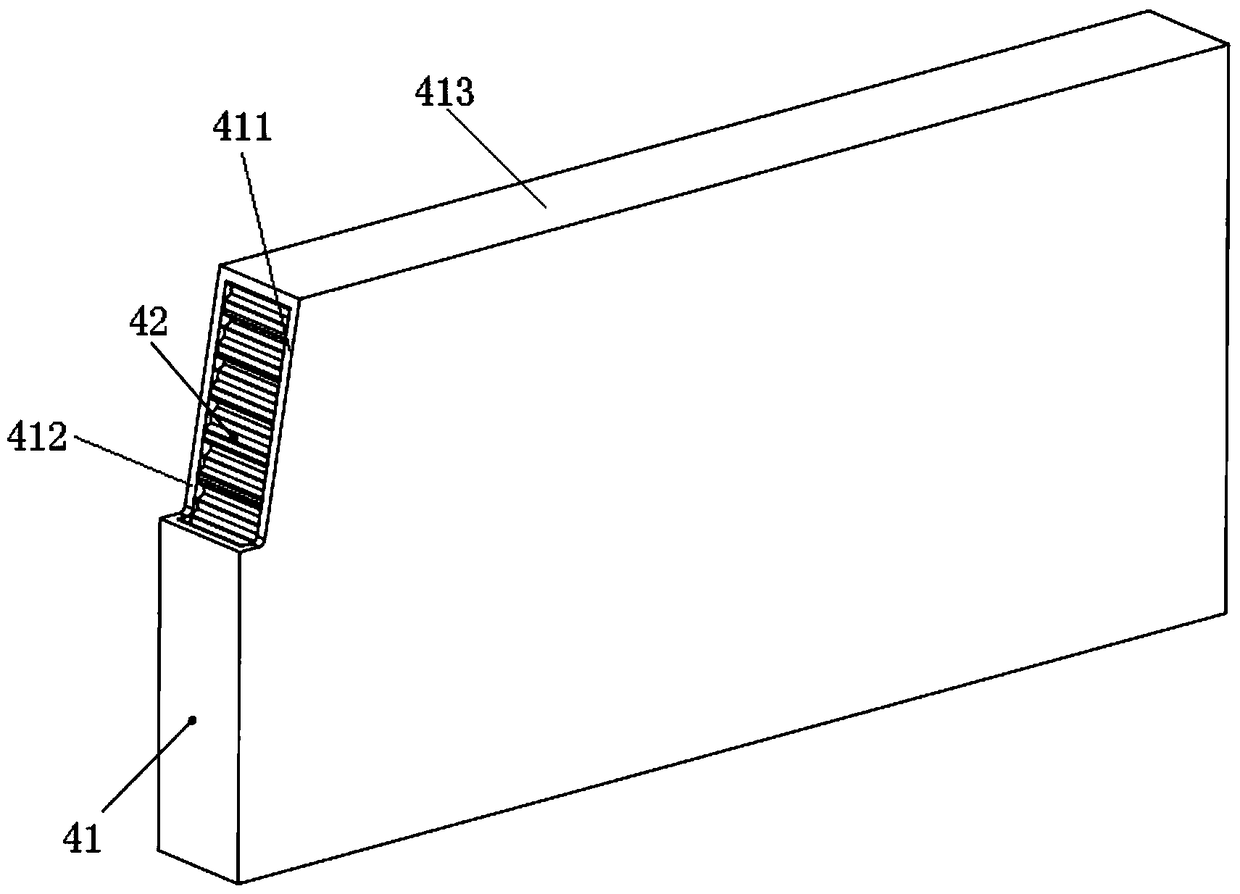

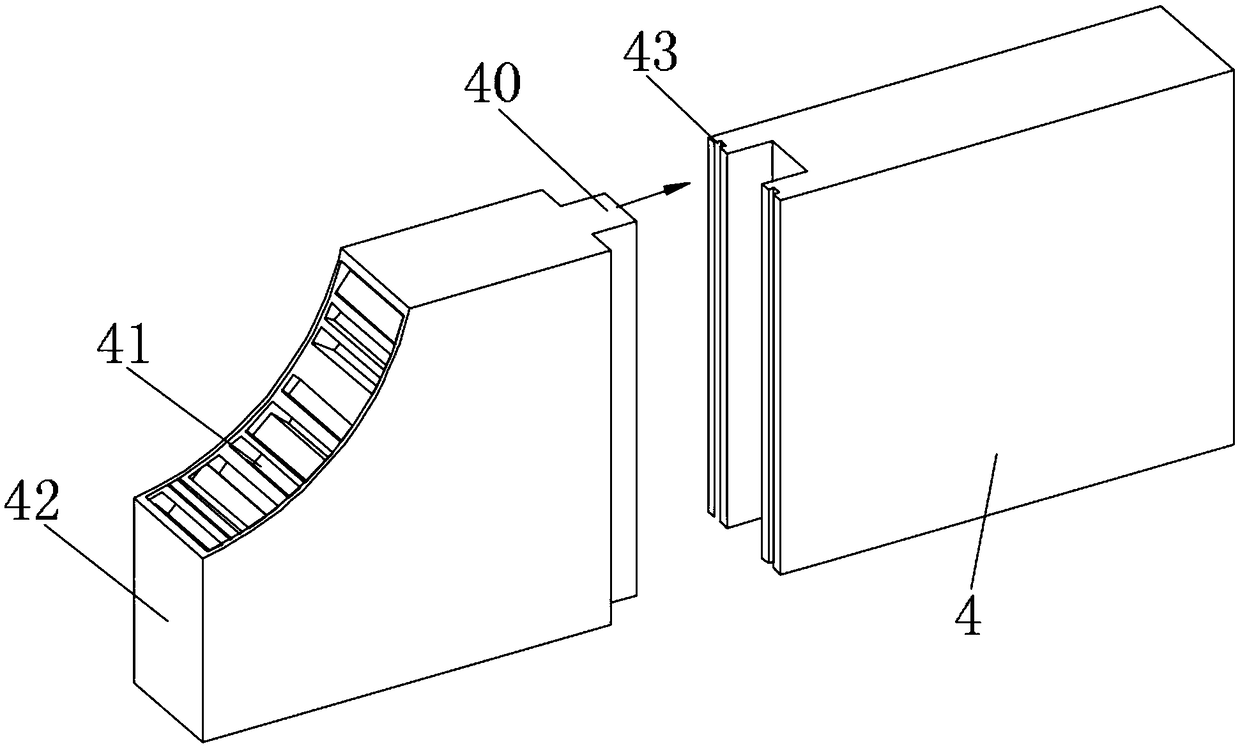

[0041] Such as Figure 1-9 The shown paint-free light-duty quick-install prefabricated wall system includes wall riser 1, bottom plate 2 and roof 3 that constitute the house, between adjacent wall risers 1, wall riser 1 and bottom plate 2 Or the top boards 3 are all connected by the first connection mechanism, and the wall vertical board 1 is formed by splicing several light-weight solid surface material board units 4 through the tenon structure 40. In addition, the wall vertical board 1 can be preset with Window frame installation position, door frame installation position, air outlet position of central air conditioner;

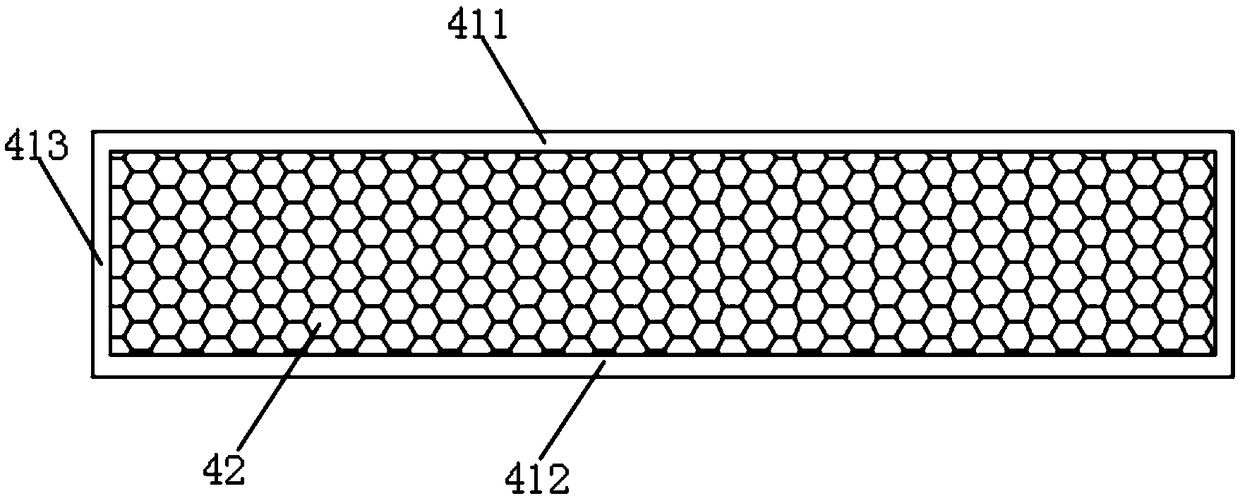

[0042] Wherein, the lightweight solid surface material panel unit 4 includes a solid panel 41 surrounded by external sealing and a lightweight sandwich 42 filled inside. The solid panel 41 includes a front panel 411, a back panel 412 and an edge panel 413, and the front panel 411 and the back panel 412 The size is consistent, and the edge banding plate 413 s...

Embodiment 2

[0050] Such as Figure 10-12 As shown, the painting-free light-duty quick-install prefabricated wall system of this embodiment is different from the embodiment in that the first connection mechanism is a corner connector 8, and the corner connector 8 includes an adhesive surface and the slot surface, the slot surface is provided with a slot 81, and one side of the slot 81 is also provided with an R angle transition area 82, and the R angle transition area 82 makes the included angle between two adjacent wall risers 1 have a Arc transition, more beautiful.

[0051] When two adjacent wall risers 1 are to be connected, place the corner connector 8 vertically, apply glue on the bonding surface of the corner connector 8 and bond it to one of the wall risers 1, after the glue dries, insert another wall riser 1 into the slot 81 of the corner connector 8 to complete the connection of the two wall risers 1; when the wall riser 1 and When connecting the bottom plate 2 or the top plate...

Embodiment 3

[0054] Such as Figure 13 As shown, when there is no bottom plate 2 and / or top plate 3 and the wall vertical plate 1 needs to be installed directly, a 30mm hole 90 can be preset on the bottom surface of the prefabricated cement board, and a 50mm deep hole can be preset on the top surface of the prefabricated cement board The slots 90 are used for inserting the top and bottom of the wall vertical board 1 into the hole grooves 90 of the prefabricated cement board respectively, so as to fix the wall vertical board 1 . Among them, a sealant groove pad 91 is provided in the hole 90 inserted into the bottom of the wall riser 1 for waterproof sealing, and elastic sealant strips 92 are arranged on both sides of the upper part of the wall riser 1 for insertion into the upper part. In the hole groove 90, the rear elastic sealing strip cooperates with the hole groove 90 on the top to play a sealing role. Such as Figure 14 As shown, when the prefabricated cement board is inconvenient t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com