An oily coating and nano-ceramic fiber composite diaphragm and a preparation method thereof

A technology of nano-ceramic fiber and composite diaphragm, which is applied in the field of preparation of oil-based coating and nano-ceramic fiber composite diaphragm, and oil-based coating and nano-ceramic fiber composite diaphragm. Separator shrinkage and other issues, to achieve the effects of convenient processing and transportation, improved mechanical properties and thermal stability, and strong batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

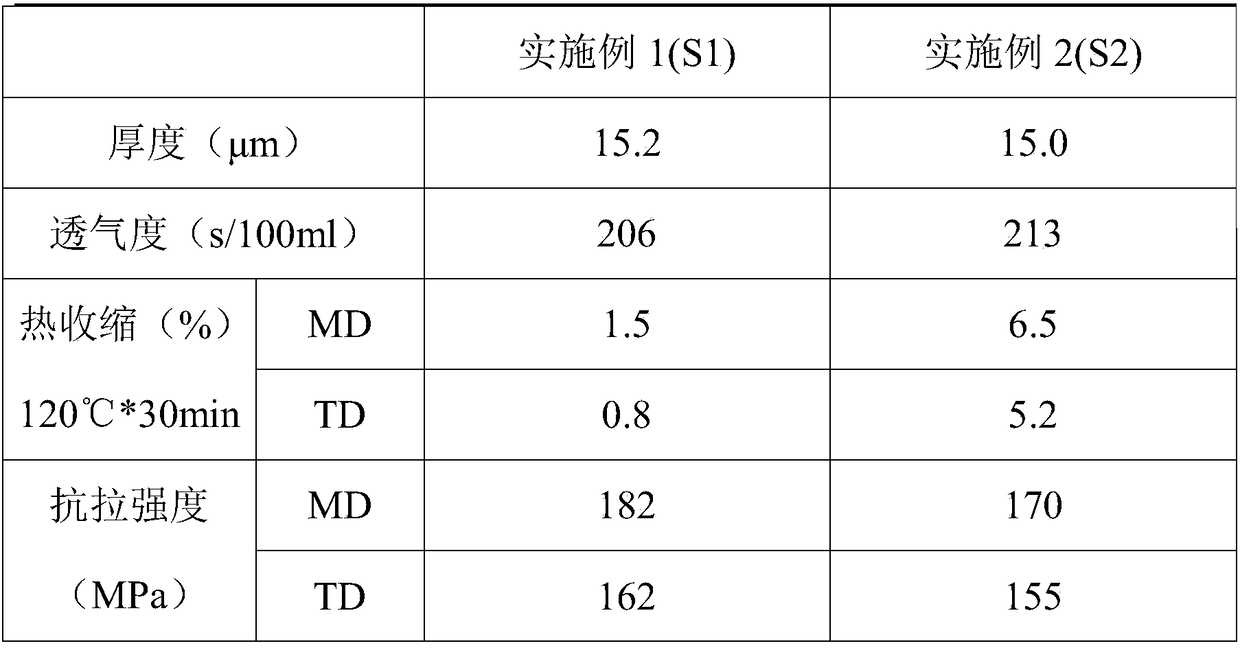

Examples

Embodiment 1

[0025] An oily coating and nano-ceramic fiber composite membrane of the present invention, the composite membrane is composed of the following components: the polymer material is polyvinylidene fluoride, the nano-ceramic fiber is attapulgite fiber powder, and the binder is Polyacrylate, dispersant are polyethylene glycol and sodium carboxymethyl cellulose, pore forming agent is hydroxyethyl cellulose and organic solvent is N-methylpyrrolidone and dimethyl sulfoxide, wherein the mass of each component Ratio: 10 for attapulgite fiber powder, 0.2 for polyethylene glycol, 80 for N-methylpyrrolidone, 8 for polyvinylidene fluoride, 0.5 for hydroxyethyl cellulose, and 0.4 for sodium carboxymethyl cellulose , 3 for polyacrylate and 10 for dimethyl sulfoxide.

[0026] The nano-ceramic fiber has an average length of 0.5 μm-2 μm, preferably 1 μm, and an average diameter of 0.05 μm-0.3 μm, preferably 0.1 μm.

[0027] A preparation method of an oily coating and a nano-ceramic fiber compos...

Embodiment 2

[0035] An oily coating and nano-ceramic fiber composite diaphragm of the present invention, the composite diaphragm is composed of the following components: the polymer material is polyvinylidene fluoride, the binder is polyacrylate, and the dispersant is carboxymethyl fiber Sodium plain, pore forming agent is hydroxyethyl cellulose and organic solvent is N-methylpyrrolidone and dimethyl sulfoxide, wherein, the mass ratio of each component is: polyvinylidene fluoride is 8, hydroxyethyl cellulose 0.5, 0.4 for sodium carboxymethylcellulose, 3 for polyacrylate, 10 for dimethyl sulfoxide, and 80 for N-methylpyrrolidone.

[0036] A preparation method of an oily coating and a nano-ceramic fiber composite diaphragm, the preparation method of the composite diaphragm comprises the following steps:

[0037] Step 1: Disperse polyvinylidene fluoride in a mixed solvent of N-methylpyrrolidone and dimethyl sulfoxide, and fully stir for 1-3 hours at a stirring speed of 1000-3000 rpm. The pref...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com