Mixed slurry for preparing composite diaphragm and preparation method of composite diaphragm

A composite membrane, mixed slurry technology, applied in nanotechnology, electrical components, nanotechnology, etc. for materials and surface science, can solve the problems of low adhesion, poor adhesion, unfavorable battery processing and transportation, etc. , to achieve the effects of enhanced adhesion, improved tensile strength, and excellent electrolyte absorption and retention capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

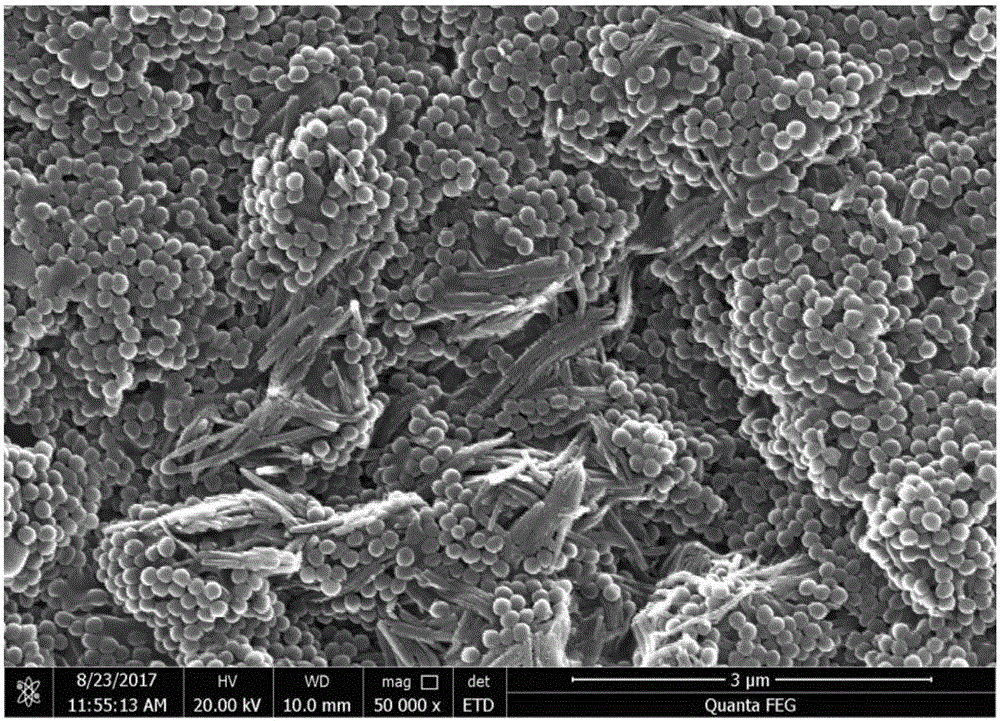

Image

Examples

preparation example Construction

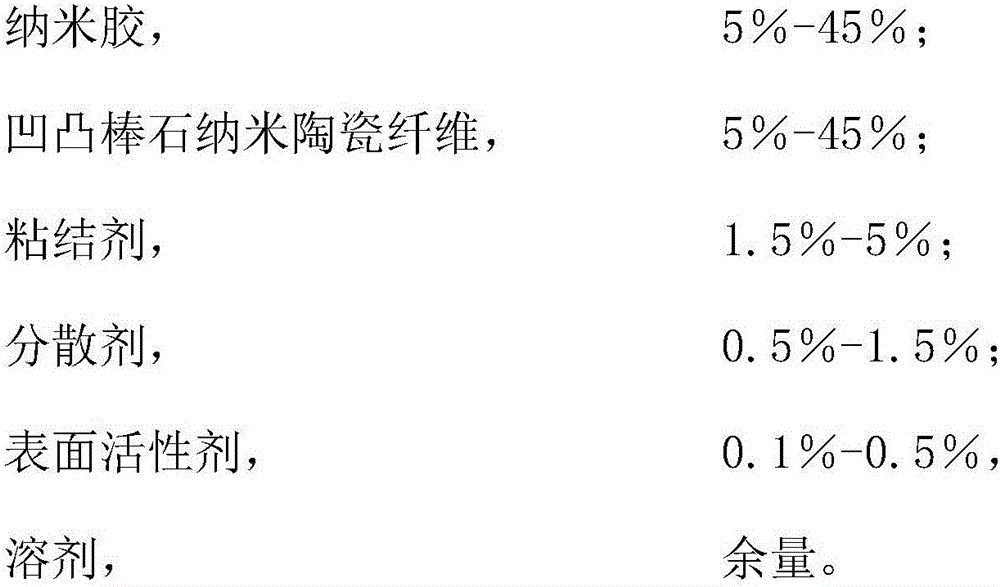

[0028] A method for preparing a composite diaphragm, comprising the following steps: step S1) preparing the mixed slurry; the step S1) comprising the following steps: step S11) dissolving the attapulgite nano-ceramic fiber and a dispersant in a solvent , and fully stirred; step S12) adding nano glue, binder and surfactant to the solution in step S11), and fully mixing and stirring to prepare the mixed slurry.

[0029] Step S2) coating the mixed slurry on the surface of the porous polymer membrane to form a separator layer of nano glue and attapulgite nano ceramic fibers. In the present invention, coating may be performed on both sides of the porous polymer membrane, or may be applied on one side of the porous polymer membrane. The porous polymer film is a polyethylene base film, a polypropylene base film, a polypropylene / polyethylene / polypropylene composite base film, a polyimide base film, a nano glue base film, a polyethylene non-woven fabric base film, a poly One of acryli...

Embodiment 1

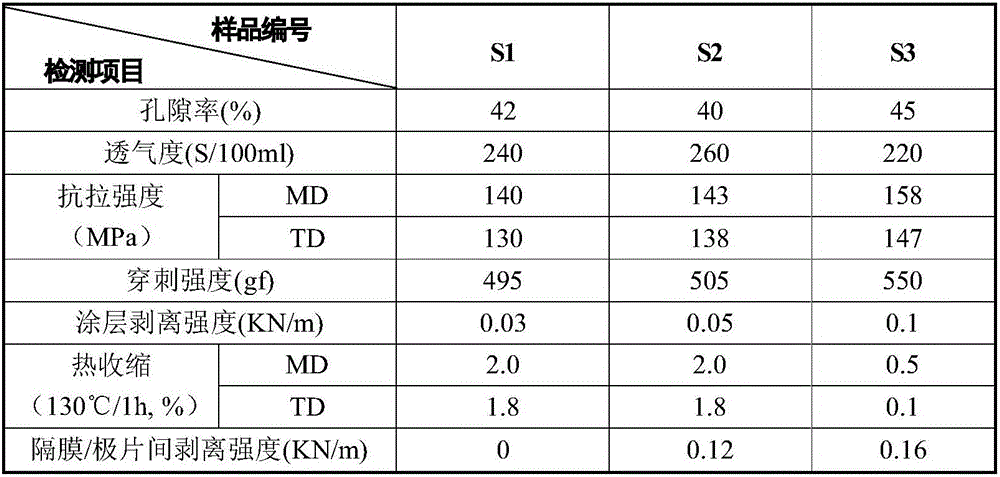

[0031] Example 1, this example is a common method for preparing a diaphragm, an alumina particle diaphragm.

[0032] 20g of alumina particles, 0.6g of sodium carboxymethylcellulose and 40g of deionized water were stirred in a high-speed disperser at a speed of 3000 rpm for 1 hour. Add 0.5 g of fluoroalkyl methoxy ether alcohol, 0.4 g of sodium carboxymethyl cellulose, 3 g of polyacrylate and 16 g of deionized water again, and stir for 3 h at a speed of 2000 rpm. The resulting slurry was coated on one side with a micro-gravure coater on a polyethylene film with a thickness of 12 microns, and dried at 60°C to obtain a composite separator of alumina particles with a total thickness of 16 microns, marked as S1.

Embodiment 2

[0033] Embodiment 2, this embodiment is the preparation method of the composite membrane of nano glue and alumina particles.

[0034]20g of alumina particles, 0.6g of sodium carboxymethylcellulose and 40g of deionized water were stirred in a high-speed disperser at a speed of 3000 rpm for 1 hour. Add 10g of nano glue emulsion, 0.5g of fluoroalkyl methoxy ether alcohol, 0.4g of sodium carboxymethylcellulose, 3g of polyacrylate and 16g of deionized water again, and stir for 3 hours at a speed of 2000 rpm. The resulting slurry was coated on one side with a micro-gravure coater on a polyethylene film with a thickness of 12 microns, and dried at 60°C to obtain a composite separator of nano-glue and alumina particles with a total thickness of 16 microns, marked as S2 . .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com