Phosphorus removal material aiming to low-concentration phosphorus, and preparation method and application of same

A low-concentration, sodium alginate technology, applied in chemical instruments and methods, other chemical processes, water treatment parameter control and other directions, to achieve the effect of convenient recycling, avoiding secondary pollution and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for preparing a phosphorus-removing material for low-concentration phosphorus, comprising the steps of:

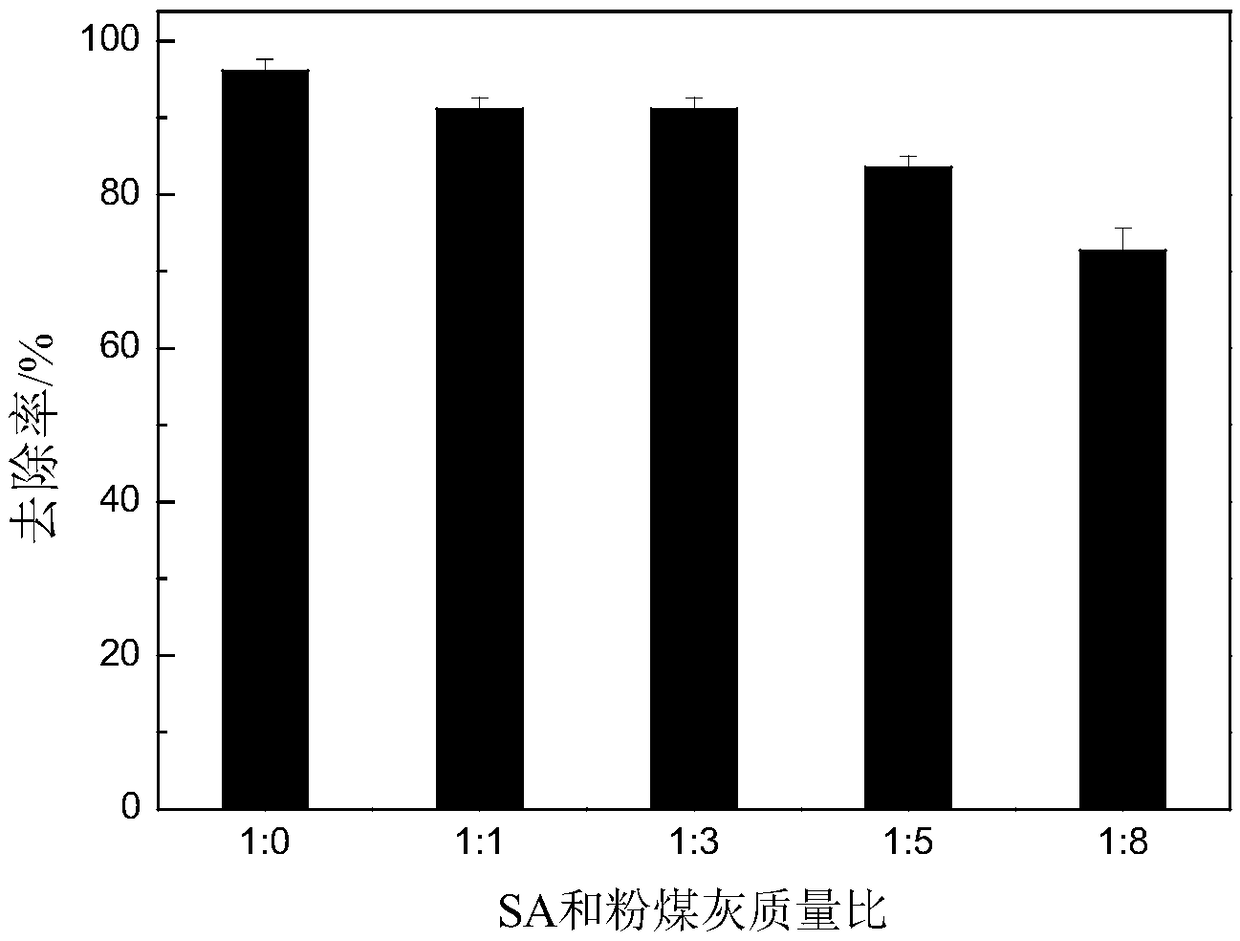

[0026] (1) According to the mass ratio of 1:3, weigh sodium alginate and fly ash respectively for later use, add sodium alginate to deionized water to prepare a 2wt.% sodium alginate solution, and stir vigorously at 70-90°C Make it completely dissolved and set aside;

[0027] (2) Add the weighed fly ash into the sodium alginate solution prepared in step (1), and continue to stir for 15 to 30 minutes to make it evenly mixed to obtain a slurry;

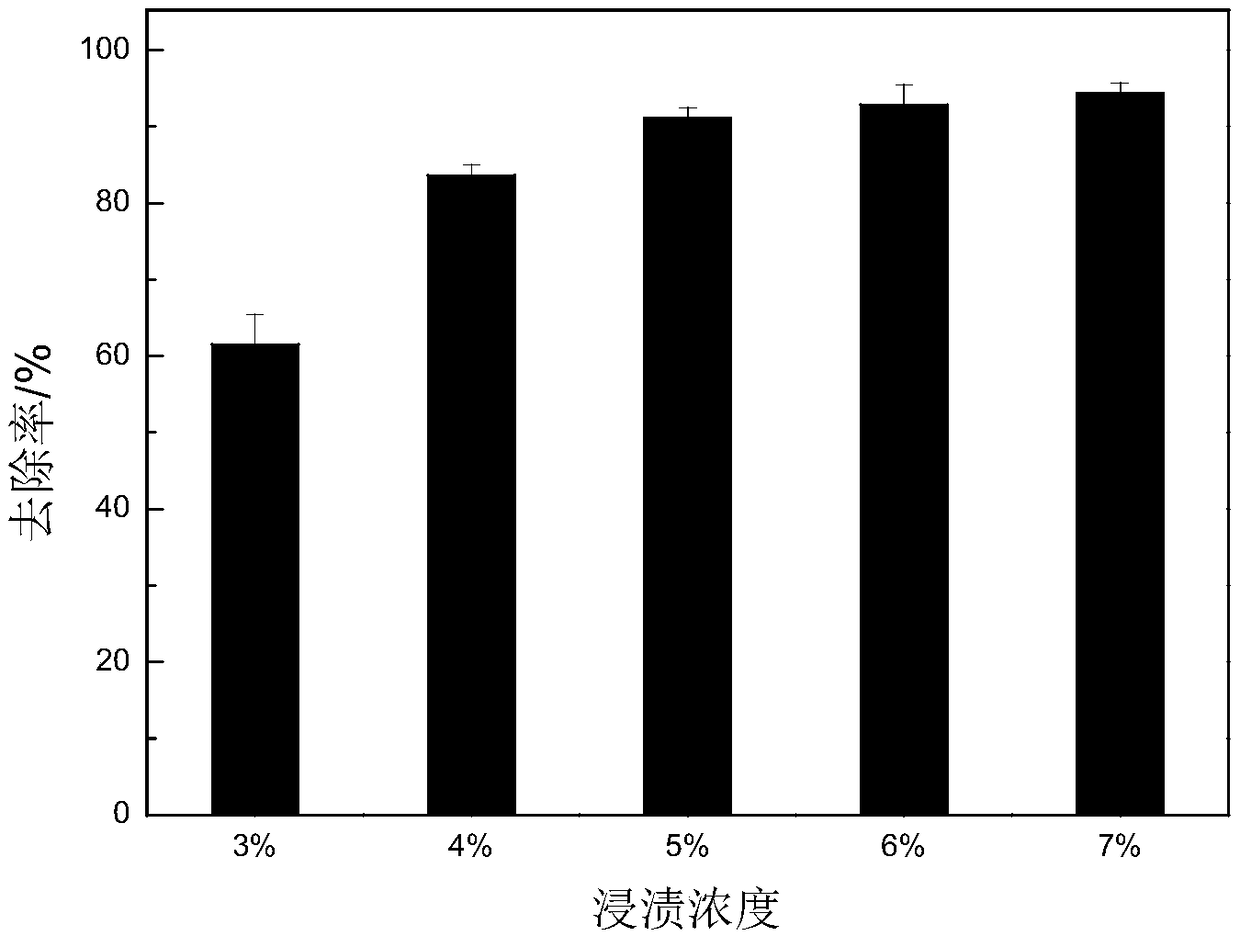

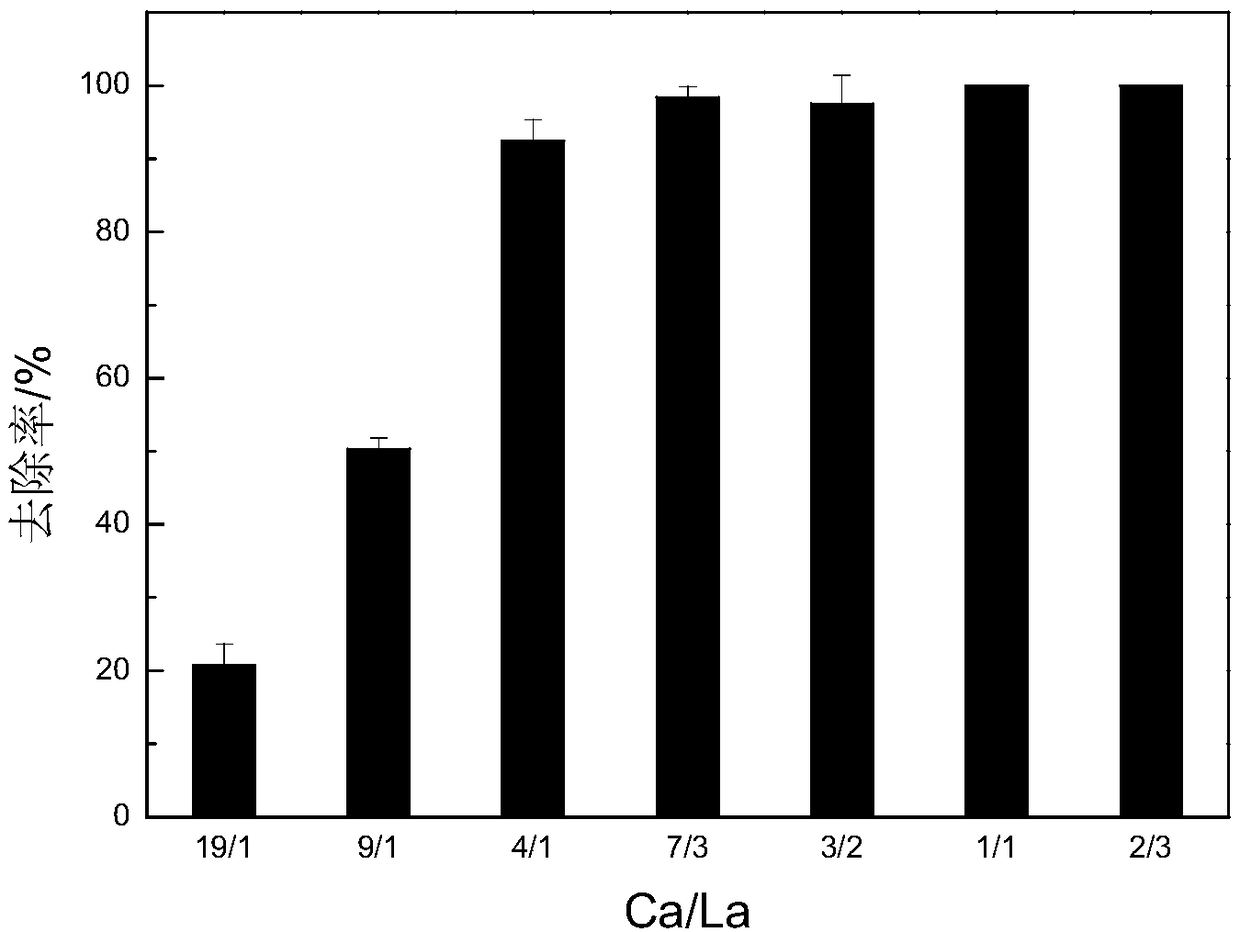

[0028] (3) Weigh LaCl respectively according to the mass ratio of lanthanum to calcium of 1:4 3 ·nH 2 O and anhydrous CaCl 2 Standby, add deionized water to prepare a 5wt.% mixed ion solution, and set aside;

[0029] (4) Add the slurry in the above step (2) dropwise into the mixed solution of step (3) at a constant speed with a syringe with a needle aperture of 1-3 mm, crosslink for 10 hours and form microspheres...

Embodiment 2

[0032] (1) According to the mass ratio of 1:6, weigh sodium alginate and fly ash respectively for later use, add sodium alginate into deionized water to prepare a 2wt.% sodium alginate solution, and stir vigorously at 70-90°C Make it completely dissolved and set aside;

[0033] (2) Add the weighed fly ash into the sodium alginate solution prepared in step (1), and continue to stir for 15 to 30 minutes to make it evenly mixed to obtain a slurry;

[0034] (3) Weigh LaCl respectively according to the mass ratio of lanthanum to calcium of 1:4 3 ·nH 2 O and anhydrous CaCl 2 Standby, add deionized water to prepare a 5wt.% mixed ion solution, and set aside;

[0035] (4) Add the slurry in the above step (2) dropwise into the mixed solution of step (3) at a constant speed with a syringe with a needle aperture of 1-3 mm, crosslink for 10 hours and form microspheres;

[0036] (5) The microspheres were repeatedly washed with ultrapure water for 3 to 5 times to remove uncrosslinked met...

Embodiment 3

[0038] (1) According to the mass ratio of 1:3, weigh sodium alginate and fly ash respectively for later use, add sodium alginate to deionized water to prepare a 2wt.% sodium alginate solution, and stir vigorously at 70-90°C Make it completely dissolved and set aside;

[0039] (2) Add the weighed fly ash into the sodium alginate solution prepared in step (1), and continue to stir for 15 to 30 minutes to make it evenly mixed to obtain a slurry;

[0040] (3) Weigh LaCl respectively according to the mass ratio of lanthanum to calcium of 3:7 3 ·nH 2 O and anhydrous CaCl 2 Standby, add deionized water to prepare a 5wt.% mixed ion solution, and set aside;

[0041] (4) Add the slurry in the above step (2) dropwise into the mixed solution of step (3) at a constant speed with a syringe with a needle aperture of 1-3 mm, crosslink for 10 hours and form microspheres;

[0042] (5) The microspheres were repeatedly washed with ultrapure water for 3 to 5 times to remove uncrosslinked metal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com