Oxidation catalyst for soot particles of diesel and preparation method thereof

A soot particle and catalyst technology, which is applied in the field of oxidation catalyst and its preparation, can solve the problems of affecting oxygen storage capacity, specific surface pore volume deterioration and collapse, and poor high temperature stability, so as to improve dispersion and achieve coating uniformity , no plugging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

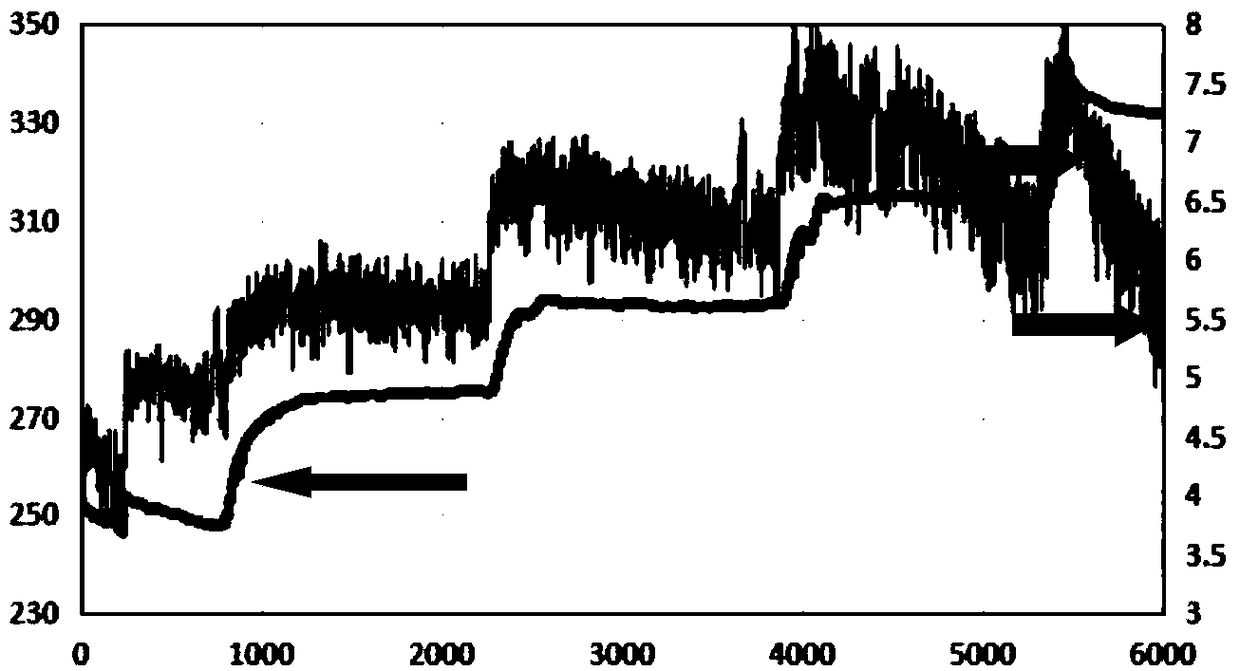

Embodiment 1

[0033] Catalyst preparation one, comprises the steps:

[0034] 1) Slurry configuration: according to the preferred coating material cerium oxide-praseodymium oxide-lanthanum oxide, its oxide weight composition percentage: 90:5:5, choose platinum nitrate and palladium nitrate salt solution, pH: 3.0, D 90 =7.0 μm, the solid content is 13%, stirred and ball milled.

[0035] 2) Coating: Coating is carried out according to the loading amount of 20g / L coating, and the loading amount of precious metal is 3.0g / ft 3 .

[0036] 3) Drying: Dry the coated catalyst at 105°C for 2.0 hours.

[0037] 4) Roasting: put the dried catalyst in a mesh belt furnace for calcination, the atmosphere is air, and calcine at 650° C. for 4 hours to complete the calcination process. The coating amount of the catalytic material on a dry basis is 18 g / L.

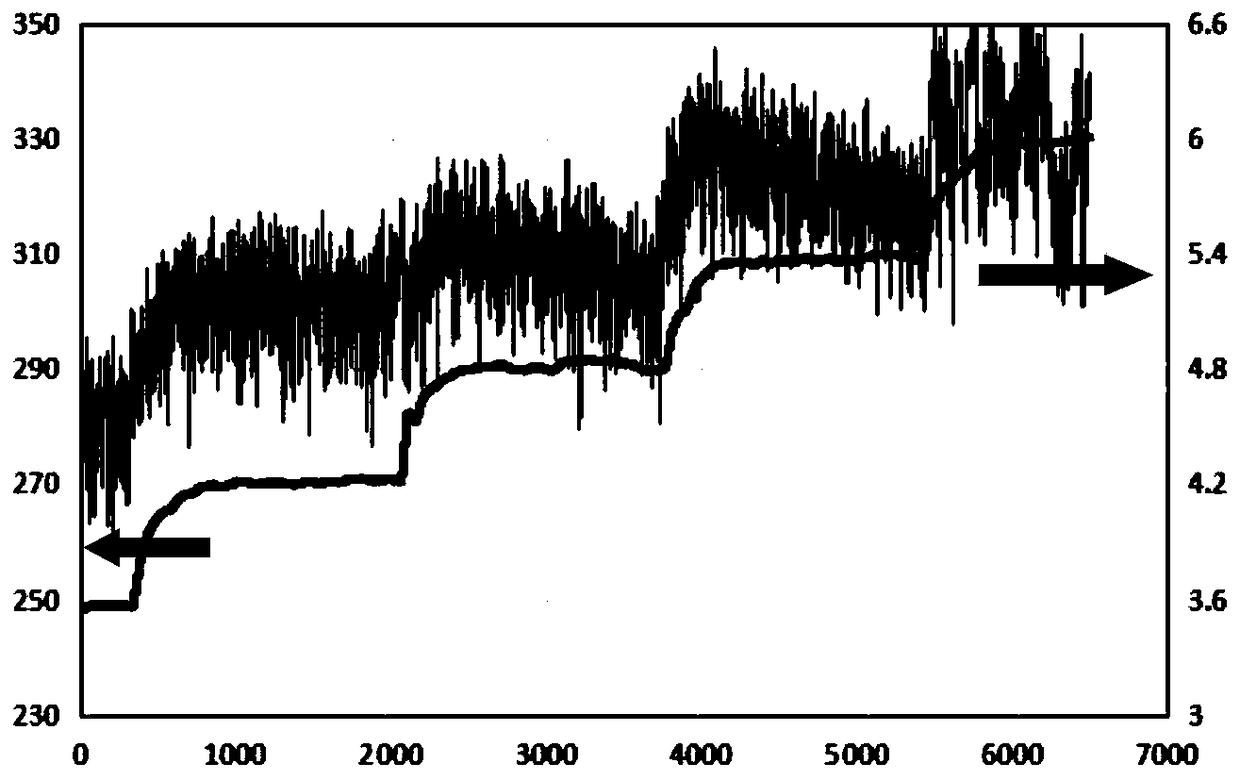

Embodiment 2

[0039] Catalyst preparation two, comprises the steps:

[0040] 1) The configuration of the slurry: according to the preferred coating material ceria-praseodymia-zirconia, its oxide weight composition percentage: 80:5:15, choose platinum nitrate and palladium nitrate salt solution, pH: 3.5, D 90 =7.3 μm, the solid content is 13%, stirred and ball milled.

[0041] 2) Coating: Coating is carried out according to the loading amount of 20g / L coating, and the loading amount of precious metal is 1.0g / ft 3 .

[0042] 3) Drying: Dry the coated catalyst at 105°C for 2.5 hours.

[0043] 4) Roasting: Put the dried catalyst in a mesh belt furnace for calcination, the atmosphere is air, and calcine at 650° C. for 4 hours to complete the calcination process, and the coating amount of the catalytic material on a dry basis is 22 g / L.

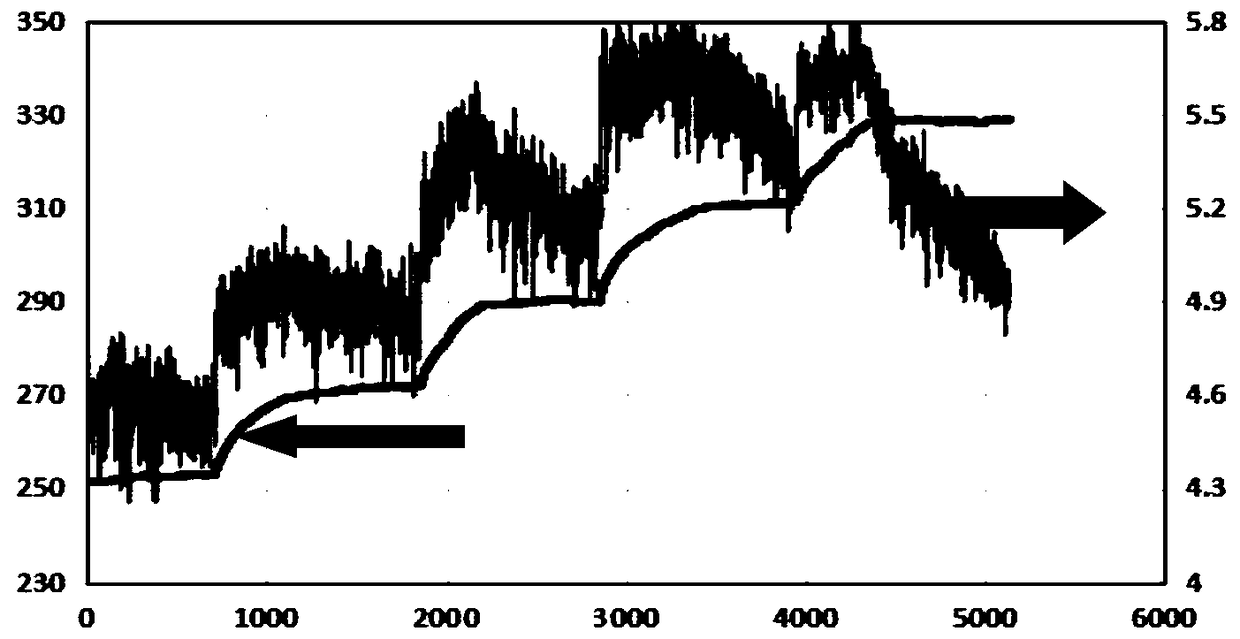

Embodiment 3

[0045] Catalyst preparation three, comprises the steps:

[0046] 1) Slurry configuration: according to the preferred coating material cerium oxide-praseodymium oxide-silver oxide, its oxide weight composition percentage: 95:4:1, choose platinum nitrate and palladium nitrate salt solution, pH: 4.0, D 90 =6.2 μm, the solid content was 12.3%, stirred and ball milled.

[0047] 2) Coating: Coating is carried out according to the loading amount of 20g / L coating, and the loading amount of precious metal is 1.0g / ft 3 .

[0048] 3) Drying: Dry the coated catalyst at 105°C for 3 hours.

[0049] 4) Roasting: put the dried catalyst in a mesh belt furnace for calcination, the atmosphere is air, and calcine at 650° C. for 4 hours to complete the calcination process. The coating amount of the catalytic material on a dry basis is 19.0 g / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com