High efficient printing and dyeing wastewater flocculating device and applications thereof

A printing and dyeing wastewater and flocculation device technology, which is applied in the direction of flocculation/sedimentation water/sewage treatment, water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problem of low decolorization efficiency of a single flocculant and poor concentration accuracy of prepared liquid , can not be continuously automatic dispensing and other problems, to achieve the effect of compact structure, narrow molecular weight distribution, and weak negative charge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

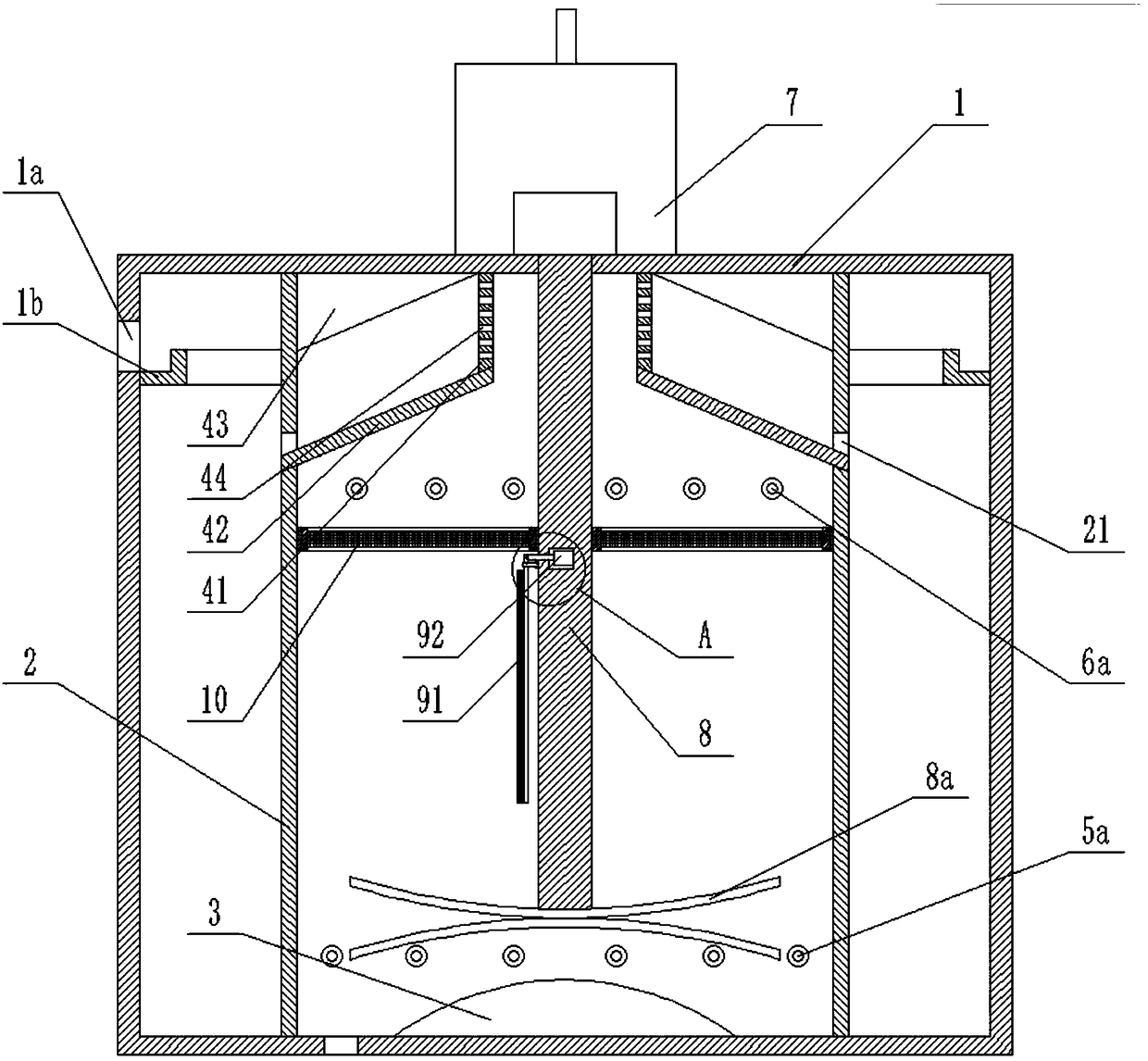

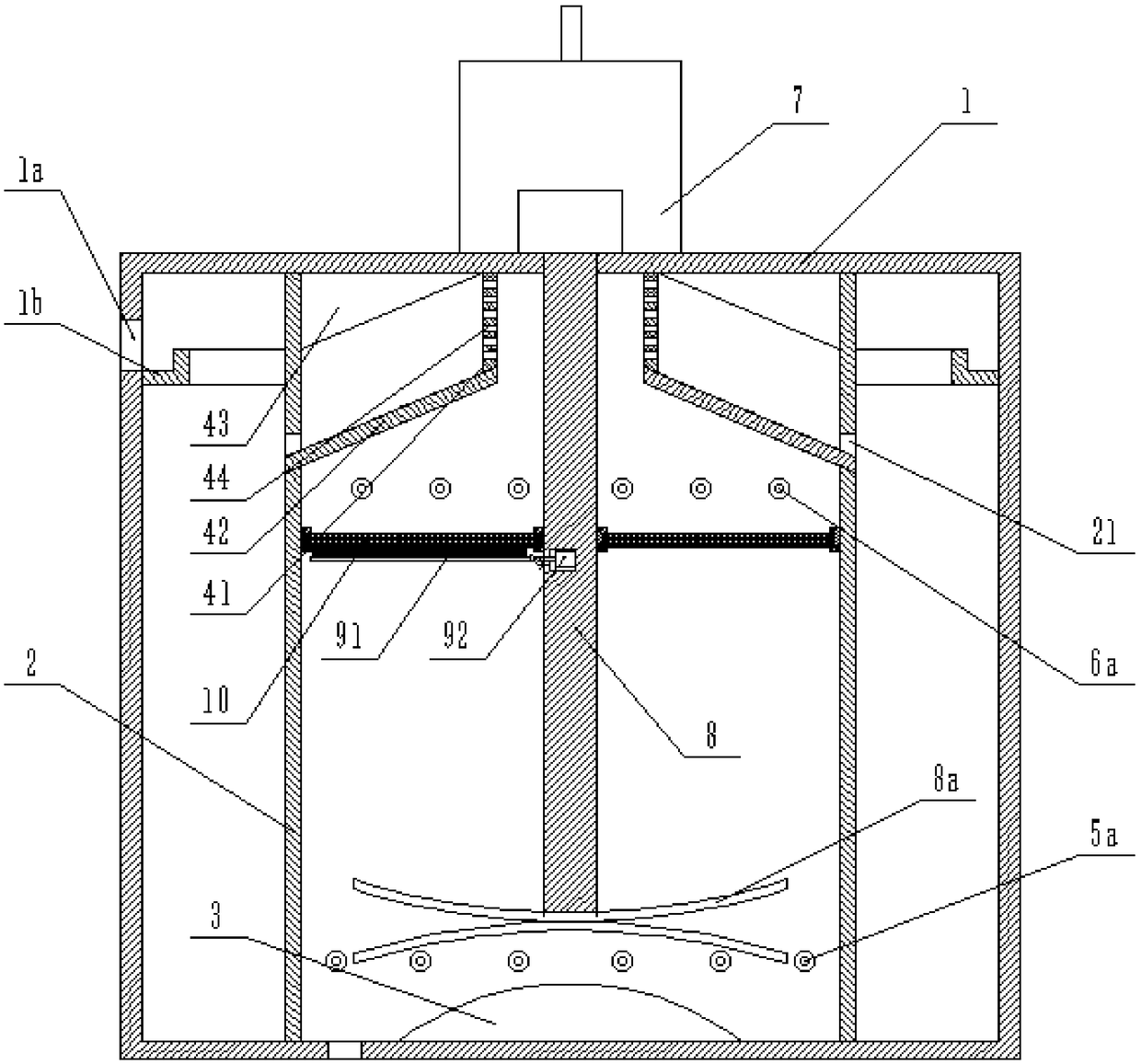

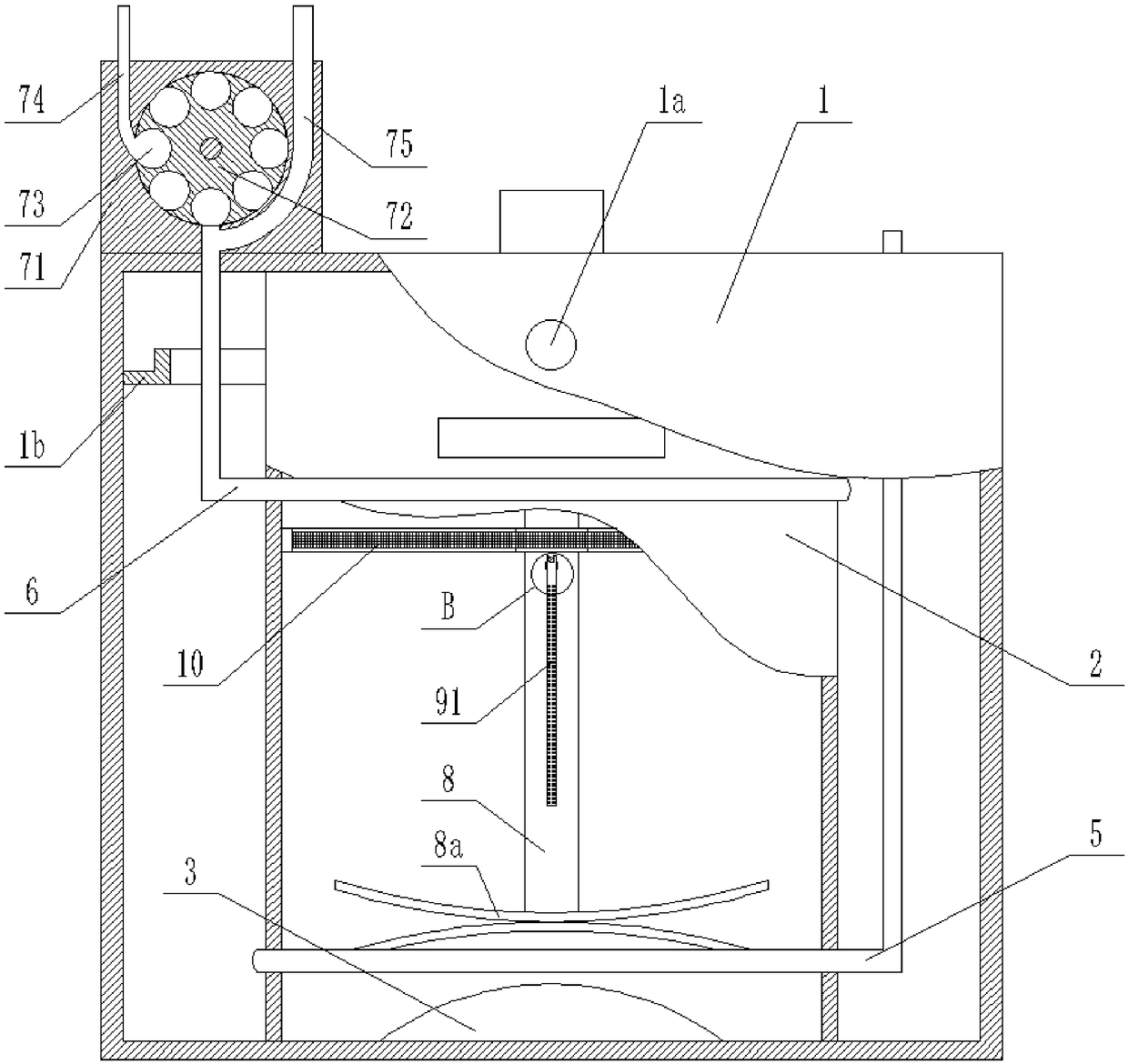

[0030] Such as Figure 1-5 As shown, a high-efficiency flocculation device for printing and dyeing wastewater includes a pool body 1, and a coagulation cylinder 2 is vertically arranged in the pool body 1, and the coagulation cylinder 2 separates the pool body 1 into a water purification area and a water purification area. In the muddy water area, the bottom and top of the muddy water area are respectively equipped with a heater 3 and a condensation separation assembly 4. The upper wall of the coagulation cylinder 2 is provided with a condensate outlet 21, and the water purification area is provided with a liquid inlet Pipe 5 and drug inlet tube 6, the liquid outlet of the liquid inlet tube 5 and the drug outlet of the drug inlet tube 6 are respectively communicated with the coagulation cylinder 2, and the drug inlet of the drug inlet tube 6 is connected to There is a quantitative dosing device 7, the side wall of the pool body 1 is provided with a water purification port 1a, ...

Embodiment 2

[0035] Embodiment 2 uses efficient flocculation device to process the method I of printing and dyeing wastewater

[0036] Step 1. Lead the printing and dyeing wastewater into the coagulation cylinder 2 through the liquid inlet pipe 5, and start the stirring device;

[0037] Step 2: Fill the flocculant I into each material storage circular tank 73 through the medicine feeding pipe 6, and the solution enters the mixing tank 71 through the water agent pipe 75, and add 300mg flocculant I to 1L of waste water to control the feeding tray The number of turns of 72 rotations is used for quantitative dosing. After the flocculant is dissolved in the dissolving solution, it is introduced into the coagulation cylinder 2 through the drug feeding pipe 6;

[0038] The flocculant I is prepared by the following method: add formaldehyde aqueous solution with a mass fraction of 35% into the reactor, stir and add hydrochloric acid, adjust the pH value of the system to 4, and then add The volume-...

Embodiment 3

[0041] Embodiment 3 Application of high-efficiency flocculation device to process the method II of printing and dyeing wastewater

[0042] Step 1. Lead the printing and dyeing wastewater into the coagulation cylinder 2 through the liquid inlet pipe 5, and start the stirring device;

[0043] Step 2: Fill the flocculant II into each material storage circular tank 73 through the drug feed pipe 6, and the solution enters the mixing tank 71 through the water agent pipe 75, and add 300mg flocculant II according to 1L of waste water, and control the feeding pan 72 turns to carry out quantitative dosing, after the flocculant is dissolved in the solution, it is introduced into the coagulation cylinder 2 through the drug feeding pipe 6;

[0044] The flocculant II is prepared by the following method: add formaldehyde aqueous solution with a mass fraction of 45% into the reactor, stir and add hydrochloric acid, adjust the pH value of the system to 5, and then add The volume-mass ratio of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com