High strength anti-crack cement board for municipal road and preparation method thereof

A high-strength technology for municipal roads, applied in the field of high-strength anti-cracking cement boards for municipal roads and its preparation, can solve the problems of low service life of cement boards, waste of financial expenditures, and low strength of cement boards, and achieve strong integrity, Not easy to crack and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

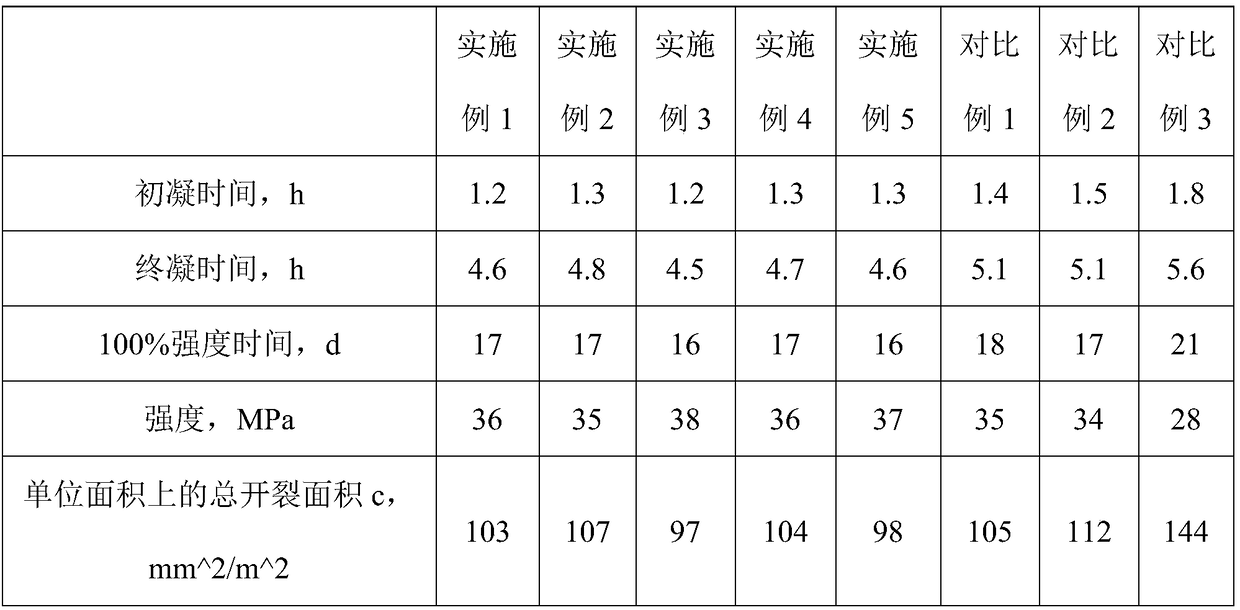

Examples

Embodiment 1

[0022] A high-strength anti-cracking cement board for municipal roads, comprising the following raw materials in parts by weight: 50 parts of gravel, 25 parts of fine sand, 20 parts of Portland cement, 6 parts of aluminate cement, and 5 parts of ultrafine mineral powder , 5 parts of vitrified microbeads, 1 part of methyl silicone oil, 4 parts of phenolic resin, 2 parts of asbestos fiber, 0.2 parts of anhydrous sodium sulfate, 0.2 parts of sodium bisulfate, 0.3 parts of polycarboxylate superplasticizer, ethylene glycol double 2 parts of stearate, 10 parts of additives, 20 parts of water.

[0023] Wherein, the particle size of the gravel is 5mm.

[0024] Wherein, the diameter of the asbestos fiber is 0.2 mm and the length is 20 mm.

[0025] Wherein, the additive is formed by mixing triethanolamine and triisopropanolamine in a weight ratio of 1:1.

[0026] In the present embodiment, the preparation method of the high-strength anti-cracking cement board for the municipal road, t...

Embodiment 2

[0032] A high-strength anti-cracking cement board for municipal roads, comprising the following raw materials in parts by weight: 60 parts of gravel, 27 parts of fine sand, 22 parts of Portland cement, 8 parts of aluminate cement, and 6 parts of ultrafine mineral powder , 6 parts of vitrified microbeads, 1.8 parts of methyl silicone oil, 7 parts of phenolic resin, 4 parts of asbestos fiber, 0.4 part of anhydrous sodium sulfate, 0.4 part of sodium bisulfate, 0.5 part of polycarboxylate superplasticizer, ethylene glycol double 3.5 parts of stearate, 14 parts of additives, 28 parts of water.

[0033] Wherein, the particle size of the gravel is 7mm.

[0034] Wherein, the diameter of the asbestos fiber is 0.4 mm and the length is 25 mm.

[0035] Wherein, the additive is formed by mixing triethanolamine and triisopropanolamine in a weight ratio of 1:1.

[0036] In the present embodiment, the preparation method of the high-strength anti-cracking cement board for the municipal road,...

Embodiment 3

[0042] A high-strength anti-cracking cement board for municipal roads, comprising the following raw materials in parts by weight: 65 parts of gravel, 30 parts of fine sand, 25 parts of Portland cement, 9 parts of aluminate cement, and 8 parts of ultrafine mineral powder , 7 parts of vitrified microbeads, 1.5 parts of methyl silicone oil, 6 parts of phenolic resin, 3.5 parts of asbestos fiber, 0.35 parts of anhydrous sodium sulfate, 0.35 parts of sodium bisulfate, 0.45 parts of polycarboxylate superplasticizer, ethylene glycol bis 3 parts of stearate, 12 parts of additives, 25 parts of water.

[0043] Wherein, the particle size of the gravel is 7mm.

[0044] Wherein, the diameter of the asbestos fiber is 0.4 mm and the length is 25 mm.

[0045] Wherein, the additive is formed by mixing triethanolamine and triisopropanolamine in a weight ratio of 1:1.

[0046] In the present embodiment, the preparation method of the high-strength anti-cracking cement board for the municipal ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com