Preparation method of waterborne epoxy emulsion

A water-based epoxy emulsion and epoxy technology, applied in the field of functional polymer materials, can solve the problems of poor acid resistance of water-based epoxy coatings, poor stability of water-based epoxy coatings, and high temperature curing, and achieve excellent emulsion stability and easy operation. , the effect of low raw material cost and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

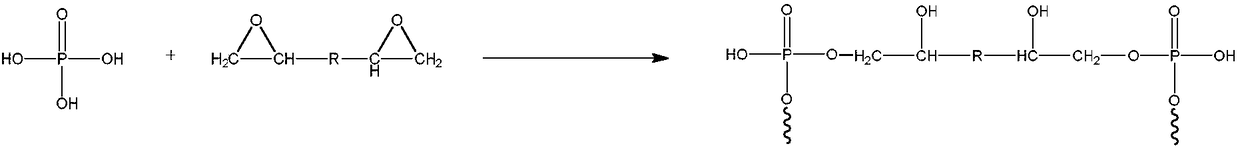

[0028] A kind of preparation method of self-emulsifying aqueous epoxy emulsion, specifically comprises the steps:

[0029] (1) Under the protection of nitrogen gas atmosphere, epoxy resin E51 (epoxy value 0.55mol / 100g, selected from Jiangsu Sanmu Chemical Co., Ltd.) and ethylene glycol butyl ether are added to the reactor, and the addition of ethylene glycol butyl ether The amount is 5mL / g of the mass volume ratio of epoxy resin, then heat the reactor to 55°C and stir at 650r / min until uniformly mixed;

[0030] (2) Slowly add phosphoric acid to the reaction vessel in step (1), the molar ratio of phosphoric acid to epoxy resin is 1:1, control the reaction temperature to 85°C after the drop, and measure the epoxy value of the system after 6 hours of reaction , until the epoxy value no longer changes, the phosphate ester type epoxy resin is obtained;

[0031] (3) Add diethanolamine slowly to the phosphate ester type epoxy resin system obtained in step (2), cool the temperature t...

Embodiment 2

[0034] A kind of preparation method of self-emulsifying aqueous epoxy emulsion, specifically comprises the steps:

[0035] (1) Under the protection of nitrogen gas atmosphere, epoxy resin E51 (epoxy value 0.50mol / 100g, selected from Jiangsu Sanmu Chemical Co., Ltd.) and propylene glycol methyl ether are added to the reactor, and the addition of propylene glycol methyl ether is epoxy The resin mass volume ratio is 3mL / g, then heat the reactor to 50°C, and stir at 600r / min until the mixture is uniform;

[0036] (2) Slowly add phosphoric acid to the reaction vessel in step (1), the molar ratio of phosphoric acid to epoxy resin is 1.1:1, control the reaction temperature to 90°C after the drop is over, and measure the epoxy value of the system after 5 hours of reaction , until the epoxy value no longer changes, the phosphate ester type epoxy resin is obtained;

[0037] (3) In the phosphate ester type epoxy resin system obtained in step (2), slowly add dimethylaminopropylamine, the...

Embodiment 3

[0040] A kind of preparation method of self-emulsifying aqueous epoxy emulsion, specifically comprises the steps:

[0041] (1) Under the protection of nitrogen gas atmosphere, epoxy resin E44 (epoxy value 0.35mol / 100g, selected from Jiangsu Sanmu Chemical Co., Ltd.) and propylene glycol methyl ether are added to the reactor, and the addition of propylene glycol methyl ether is epoxy The mass volume ratio of the resin is 8mL / g, then heat the reactor to 60°C and stir at 600r / min until the mixture is uniform;

[0042] (2) Slowly add phosphoric acid to the reaction vessel of step (1), the molar ratio of phosphoric acid to epoxy resin is 1.2:1, control the reaction temperature to be 80°C after the drop is completed, and measure the epoxy value of the system after 8 hours of reaction , until the epoxy value no longer changes, the phosphate ester type epoxy resin is obtained;

[0043] (3) Add diethanolamine slowly to the phosphate ester type epoxy resin system obtained in step (2), ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com