Polyphenylene ether composite flame retardant cable material and preparation method thereof

A compound flame retardant and polyphenylene ether technology, which is applied in the direction of circuits, electrical components, plastic/resin/wax insulators, etc., can solve the problem of poor flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

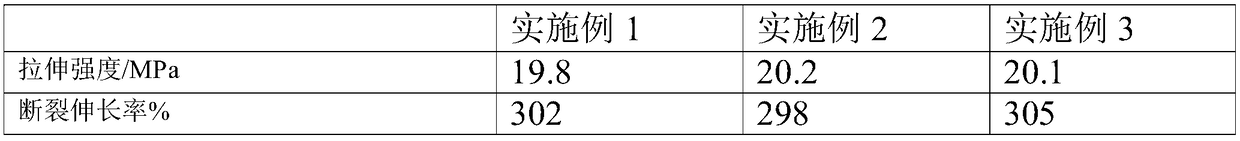

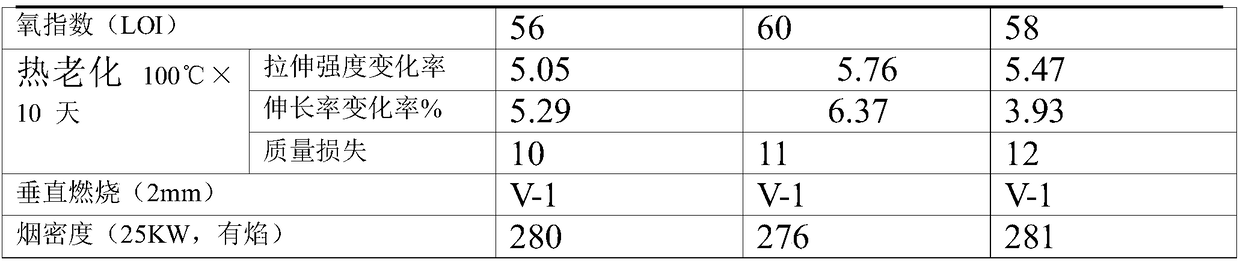

Embodiment 1

[0020] A polyphenylene ether composite flame-retardant cable material, comprising, in parts by weight, 60 parts of polyphenylene ether, 15 parts of polystyrene, 10 parts of SEBS, 15 parts of pentaerythritol oleate, 8 parts of trioctyl trimellitate, 5 parts of polytetrafluoroethylene, 1 part of antioxidant, 2 parts of anti-aging agent, 5 parts of flame retardant, 2 parts of chlorinated paraffin and 8 parts of calcium carbonate.

[0021] The polyphenylene ether adopts PPO540V from Asahi Kasei, Japan. Polystyrene adopts HIPS466F from BASF, Germany. SEBS adopts SEBS-G1660 from American Kraton. The polytetrafluoroethylene adopts PTFE MP1100 powder from DuPont of the United States.

[0022] Anti-aging agent is anti-aging agent CPPD.

[0023] Antioxidant is Antioxidant 1010.

[0024] The flame retardant is modified magnesium aluminum hydrotalcite. The preparation method of the modified magnesium aluminum hydrotalcite is as follows: Weigh 20g of magnesium aluminum hydrotalcite and...

Embodiment 2

[0030] A polyphenylene ether composite flame-retardant cable material, comprising, in parts by weight, 70 parts of polyphenylene ether, 13 parts of polystyrene, 5 parts of SEBS, 10 parts of pentaerythritol oleate, 9 parts of trioctyl trimellitate, 4 parts of polytetrafluoroethylene, 2 parts of antioxidant, 1 part of anti-aging agent, 6 parts of flame retardant, 6 parts of chlorinated paraffin and 7 parts of calcium carbonate.

[0031] The polyphenylene ether adopts PPO540V from Asahi Kasei, Japan. Polystyrene adopts HIPS466F from BASF, Germany. SEBS adopts SEBS-G1660 from American Kraton. The polytetrafluoroethylene adopts PTFE MP1100 powder from DuPont of the United States.

[0032] Anti-aging agent is anti-aging agent CPPD.

[0033] Antioxidant is Antioxidant 1010.

[0034] The flame retardant is modified magnesium aluminum hydrotalcite. The preparation method of the modified magnesium aluminum hydrotalcite is as follows: Weigh 20g of magnesium aluminum hydrotalcite and ...

Embodiment 3

[0040] A polyphenylene ether composite flame-retardant cable material, comprising 80 parts of polyphenylene ether, 10 parts of polystyrene, 8 parts of SEBS, 13 parts of pentaerythritol oleate, 10 parts of trioctyl trimellitate, and polyphenylene ether in parts by weight. 3 parts of tetrafluoroethylene, 2 parts of antioxidant, 1 part of anti-aging agent, 9 parts of flame retardant, 10 parts of chlorinated paraffin and 6 parts of calcium carbonate.

[0041] The polyphenylene ether adopts PPO540V from Asahi Kasei, Japan. Polystyrene adopts HIPS466F from BASF, Germany. SEBS adopts SEBS-G1660 from American Kraton. The polytetrafluoroethylene adopts PTFE MP1100 powder from DuPont of the United States.

[0042] Anti-aging agent is anti-aging agent CPPD.

[0043] Antioxidant is Antioxidant 1010.

[0044] The flame retardant is modified magnesium aluminum hydrotalcite. The preparation method of the modified magnesium aluminum hydrotalcite is as follows: Weigh 20g of magnesium alumi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com