A metal plate and strip roller quenching flow partition control device

A technology for metal strip and partition control, which is applied in the direction of quenching device, heat treatment process control, manufacturing tools, etc. The uniformity of water flow in the whole board and other issues can be achieved to improve drainage efficiency, not damage the surface quality, and achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

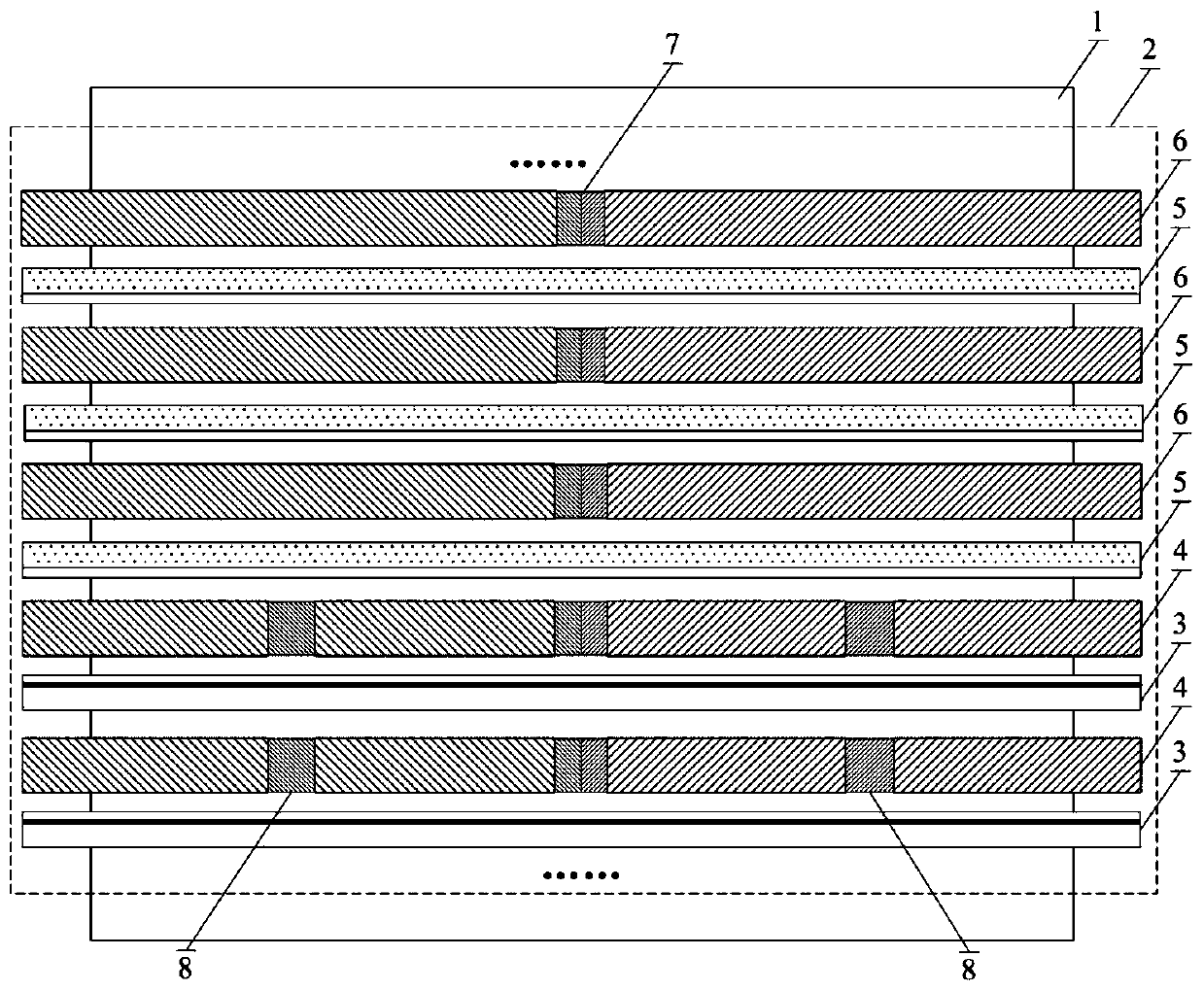

[0026] Embodiment 1 provides a specific implementation process of a metal plate and strip roll quenching flow zone control device of the present invention, such as figure 1shown. After the strip material 1 enters the high-pressure cooling section 2 of the roller quenching machine, it passes through the gap nozzle 3, the spiral roller 4 after the gap nozzle, the high-density nozzle 5 and the spiral roller 6 after the high-density nozzle in sequence. When the strip material 1 passes through the gap nozzle and the spiral roller 4, the jet cooling water in the middle of the gap nozzle 3 passes through the gap nozzle and the part of the water ring sleeve 7 in the spiral roller 4 is shunted to both sides in an orderly manner, which prevents the width of the strip material 1 from moving to the middle. The cooling water is deposited, and the cooling water is exported in an orderly and uniform manner to both sides. The cooling water near the 1 / 4 and 3 / 4 positions of the gap nozzle 3 pa...

Embodiment 2

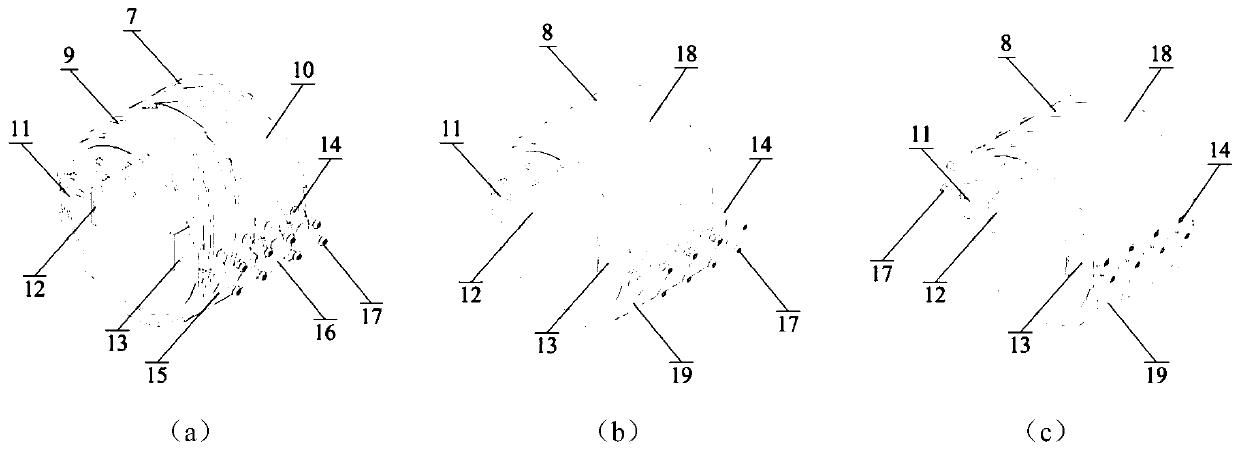

[0027] Embodiment 2 provides a specific installation process of a metal plate and strip roll quenching flow zone control device of the present invention, such as figure 1 , 2 shown. The middle part of the water ring sleeve 7 is installed in the middle processing groove of the helical roller 4 behind the gap nozzle of the high-pressure cooling section 2 of the roller quenching machine or the middle part of the helical roller 6 behind the high-density nozzle. The upper semicircular water diversion ring 10 is aligned and placed in the middle processing groove of the helical roller 4 behind the gap nozzle of the high-pressure cooling section 2 of the roller quenching machine or the middle part of the helical roller 6 behind the high-density nozzle. The connecting plate 12, the bolt fixing hole 13 on the connecting plate 12 corresponds to the bolt counterbore 14 on the outer surface of the upper left semicircular water diversion ring 9 and the upper right semicircular water divers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com