Mechanical galvanized carbon steel clamping type pipe fittings and its preparation process

A technology of press-fit pipe fittings and mechanical galvanizing, applied in metal material coating process, pressure inorganic powder coating, coating and other directions, can solve the problems of easily damaged coating, inability to galvanize, limited anti-corrosion effect of zinc layer, etc. , to achieve the effect of improving anti-corrosion performance and impact resistance, improving corrosion resistance and improving anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

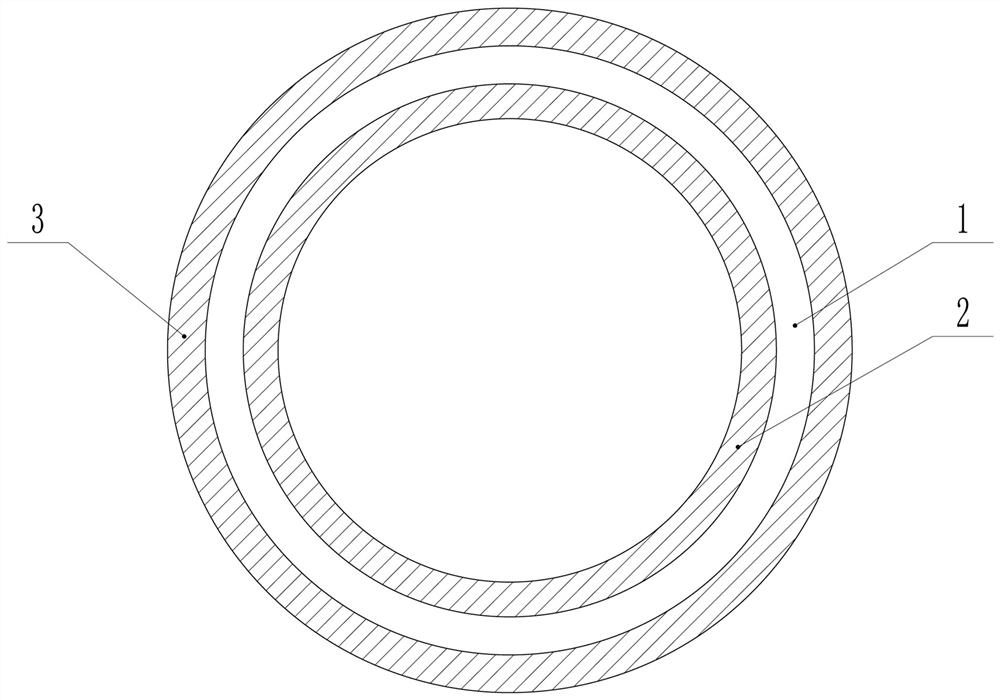

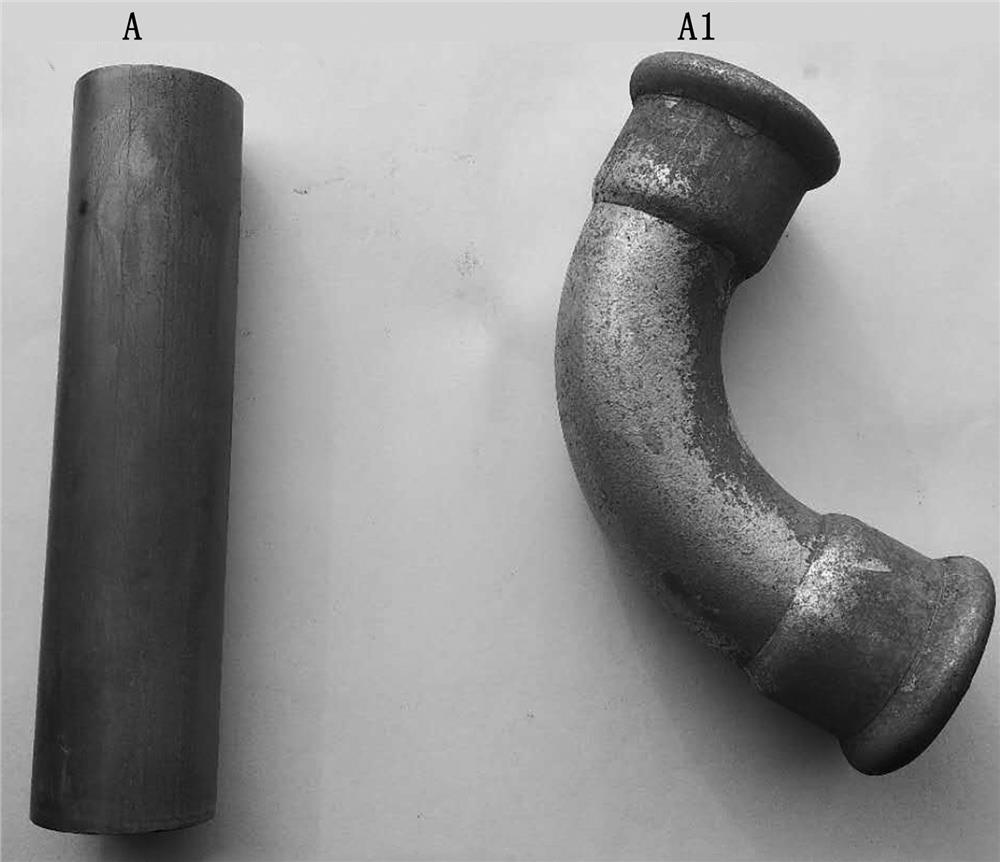

[0027] like figure 1 As shown, the present embodiment provides a mechanically galvanized carbon steel compression fitting, including a carbon steel compression fitting 1, the inner wall of the carbon steel compression fitting 1 is provided with a zinc-tin composite coating 2 and the outer wall is respectively provided with There is a zinc-tin composite coating3.

[0028] This embodiment also provides a preparation process for the mechanically galvanized carbon steel clamping type pipe fitting, including the following steps:

[0029] Pretreatment Decontamination and degreasing of carbon steel compression fittings to obtain clean carbon steel compression fittings;

[0030] Mechanical galvanizing Put the clean carbon steel clamping type pipe fittings in the mechanical galvanizing drum equipped with impact medium, first add inorganic acid to adjust the pH value to 2.5-2.8, and then slowly add galvanizing accelerator and zinc-tin mixed slurry Carry out mechanical galvanizing to o...

Embodiment 2

[0032] This embodiment provides a mechanically galvanized carbon steel compression fitting, which is basically the same in structure as the mechanically galvanized carbon steel compression fitting in Example 1, the difference being that the inner wall of the carbon steel compression fitting is the same as the A first copper transition layer is provided between the zinc-tin composite coating, and a second copper transition layer is provided between the outer wall of the carbon steel press-type pipe fitting and the zinc-tin composite coating.

[0033] This embodiment provides the preparation process of the mechanically galvanized carbon steel clamping type pipe fitting, which includes the following steps:

[0034] Pretreatment Decontamination and degreasing of carbon steel compression fittings to obtain clean carbon steel compression fittings;

[0035]Mechanical galvanizing Put the clean carbon steel clamping type pipe fittings in the mechanical galvanizing drum equipped with im...

Embodiment 3

[0037] This embodiment provides a mechanically galvanized carbon steel compression fitting, which has the same structure as that of the mechanically galvanized carbon steel compression fitting in Embodiment 2.

[0038] This embodiment provides a preparation process of the mechanically galvanized carbon steel clamping type pipe fitting, including the following steps:

[0039] Pretreatment Decontamination and degreasing of carbon steel compression fittings to obtain clean carbon steel compression fittings;

[0040] Mechanical galvanizing Put the clean carbon steel press-type pipe fittings in the mechanical galvanizing drum equipped with impact medium, add copper sulfate mixed solution, the mechanical galvanizing drum rotates for 4 minutes, first add hydrochloric acid to adjust the pH value to 2.5-2.8 , then slowly add galvanizing accelerator and zinc-tin mixed slurry for mechanical galvanizing to obtain the mechanically galvanized carbon steel clamping type pipe fitting; wherein...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com