Skin-friendly bra back button with health effect

A health-care and skin-friendly technology, applied in the field of bras, can solve the problems of easy wrinkling, poor wet fastness, and difficult recovery of fabrics, and achieve the effects of excellent fiber mechanical properties, improved hygroscopicity, and improved comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

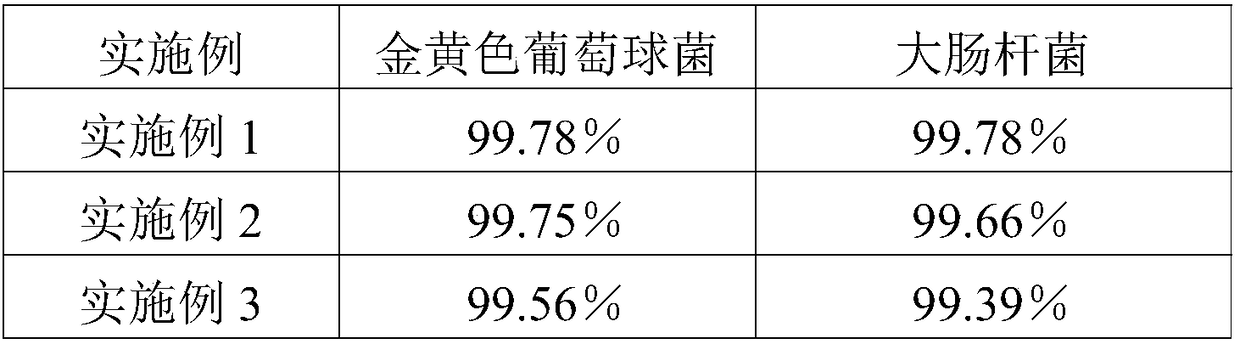

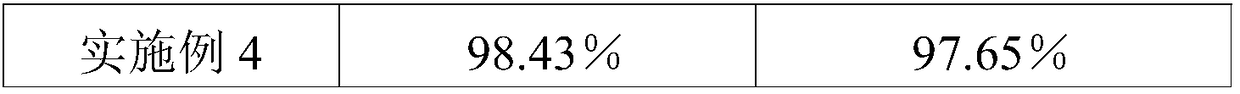

Examples

Embodiment 1

[0037] The following is the preparation process of polyester functional fiber of the present invention:

[0038] S1, drying the polyester chips, and then mixing the polyester chips and fillers in a high-speed mixer according to the mass ratio of polyester chips and fillers to 10:3, and then granulating through a twin-screw extruder to obtain polyester masterbatch body ; Wherein, the twin-screw extruder extrusion temperature is 280 ~ 320 ℃;

[0039] S2, putting the polyester masterbatch body into an aqueous solution of sodium polyacrylate containing 80wt.% of water and treating it at 70°C for 5 hours, wherein the aqueous solution of sodium polyacrylate contains 80wt.% of water;

[0040] S3, mixing the polyester masterbatch body, polyester chips, polyvinyl alcohol and polyethylene glycol, and performing melt spinning with a single-screw spinning machine at a spinning temperature of 280-305°C to obtain the polyester fiber body; Wherein, the mass ratio of polyvinyl alcohol and po...

Embodiment 2

[0046] The following is the preparation process of polyester functional fiber of the present invention:

[0047] S1, drying the polyester chips, and then mixing the polyester chips and fillers in a high-speed mixer according to the mass ratio of polyester chips and fillers to 10:3, and then granulating through a twin-screw extruder to obtain polyester masterbatch body ; Wherein, the twin-screw extruder extrusion temperature is 280 ~ 320 ℃;

[0048] S2, putting the polyester masterbatch body into an aqueous solution of sodium polyacrylate containing 80wt.% of water and treating it at 70°C for 5 hours, wherein the aqueous solution of sodium polyacrylate contains 80wt.% of water;

[0049] S3, mixing the polyester masterbatch body, polyester chips, polyvinyl alcohol and polyethylene glycol, and performing melt spinning with a single-screw spinning machine at a spinning temperature of 280-305°C to obtain the polyester fiber body; Wherein, the mass ratio of polyvinyl alcohol and po...

Embodiment 3

[0056] The preparation process of the polyester functional fiber described in this embodiment is as in Example 1, the difference is:

[0057] In this embodiment, the contents of the fillers in the polyester functional fibers are: carbon nanotubes 3wt.%, ZrO 2 Nanoparticles 0.6wt.%, TiO 2 Nanoparticles 0.3wt.%, talcum powder 2wt.%, dispersant 3wt.%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com