Nanosheet silver paste capable of magnetic conduction and orientation and preparation method thereof

A technology of nanosheets and silver pastes, applied in nanotechnology for materials and surface science, equipment for manufacturing conductive/semiconductive layers, magnetic materials, etc., can solve the problem that the advantages of nanosheet silver cannot be displayed, nano The application of sheet silver is not common, and the arrangement hinders the application of nano-sheet silver, so as to achieve the effect of no combination resistance and good combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The nanosheet silver paste that can be magnetically directed orientated includes nanosheet silver particles, and the nanosheet silver particles are nanometer-thick membranes with a structure of "silver-alloy-silver", wherein:

[0032] The monolayer thickness of described silver is 6nm;

[0033] The single layer thickness of the alloy is 8nm;

[0034] The total thickness of the nanosheet silver particles is 20 nm, and the particle size (d50) is 0.4 μm.

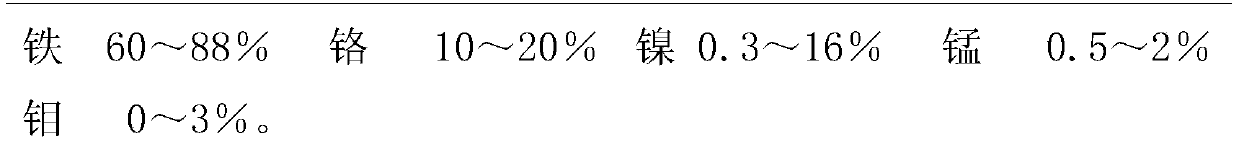

[0035] In this embodiment, the alloy is made of the alloy target material in the following weight percentages:

[0036] Iron 79.0%, Chromium 18.0%, Nickel 2.1%, Manganese 0.9%

[0037] In this embodiment, the silver is made of a silver target with a purity greater than 99.99%.

[0038] In this embodiment, the nanosheet silver paste that can be magnetically guided and oriented has a dark gray paste appearance, and it is composed of the following components by weight percentage:

[0039] Nanosheet silver particles 60% ...

Embodiment 2

[0049] The nanosheet silver paste that can be magnetically directed orientated includes nanosheet silver particles, and the nanosheet silver particles are nanometer-thick membranes with a structure of "silver-alloy-silver", wherein:

[0050] The monolayer thickness of described silver is 14nm;

[0051] The single layer thickness of the alloy is 12nm;

[0052] The total thickness of the nanosheet silver particles is 40 nm, and the particle size (d50) is 0.8 μm.

[0053] In this embodiment, the alloy is made of the alloy target material in the following weight percentages:

[0054] Iron 79.0%, Chromium 18.0%, Nickel 2.1%, Manganese 0.9%

[0055] In this embodiment, the silver is made of a silver target with a purity greater than 99.99%.

[0056]In this embodiment, the nanosheet silver paste that can be magnetically guided and oriented has a gray slurry appearance, and it is composed of the following components by weight percentage:

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com