High-efficiency wear-resistant slurry bed Fischer-Tropsch synthesis iron-based catalyst and its preparation method and application

An iron-based catalyst and Fischer-Tropsch synthesis technology, applied in the preparation of liquid hydrocarbon mixtures, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the requirements that the liquid level and pressure of the reactor cannot be kept normal, and the anti-wear performance of the catalyst High, affecting the filtering effect of the filter, etc., to achieve high Fischer-Tropsch synthesis reactivity, easy large-scale industrial production, and improve the effect of acidity and alkalinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

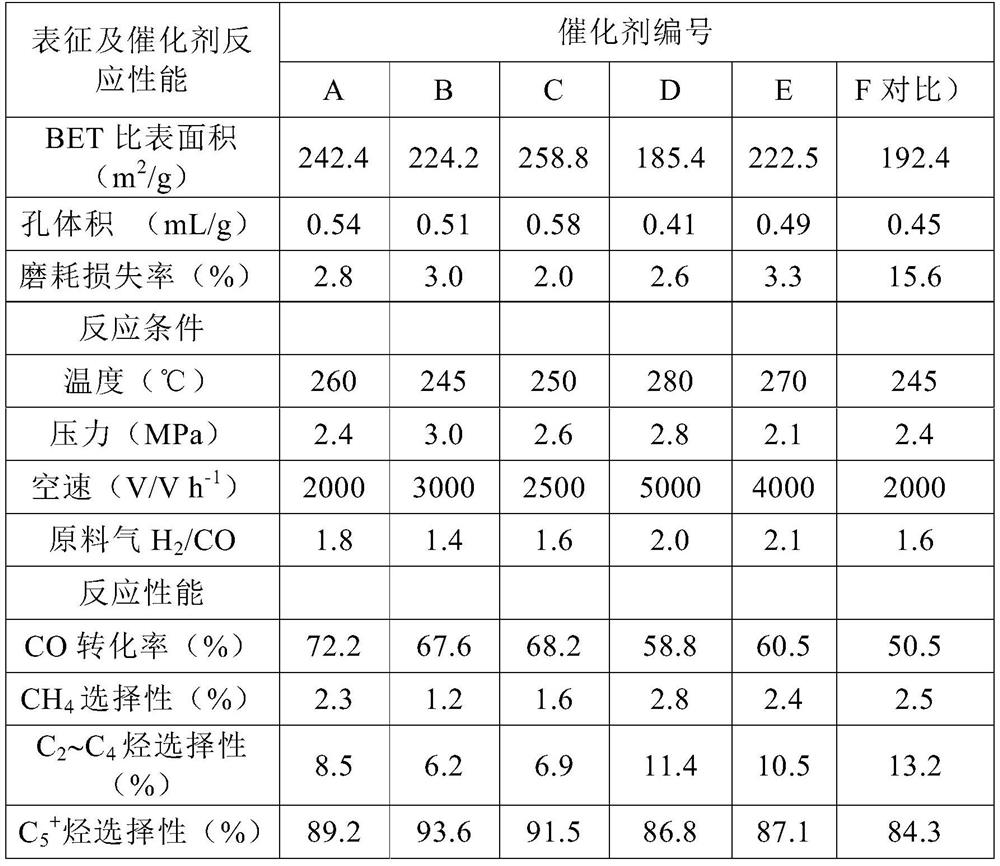

Examples

Embodiment 1

[0032] Dissolve 5kg iron powder and 283g copper powder in 45L 55wt% nitric acid solution, and dilute to obtain a metal solution, wherein the Fe content is 60g / L, and the Cu content is 3.3g / L; 0.8mol / LNa 2 CO 3 The aqueous solution was added to the reaction kettle and heated to 65°C; at the same time, the above-mentioned metal solution was also heated to 65°C, added to the reaction kettle under rapid stirring, the reaction time was 30 minutes, the pH value of the slurry was 7.5, and the coprecipitation was obtained by filtration and washing. Filter cake; Coprecipitation filter cake is added deionized water to beat again, add the potassium silicate water glass solution of 3.0kg (SiO 2 : 22.5wt%, K 2 O: 12.5 wt %), mix evenly, adjust the pH value of the slurry with nitric acid to 7.15, keep at 85° C. for 30 minutes, and filter to obtain a filter cake. The filter cake is re-slurried with water to obtain a co-precipitated filter cake. 1.0kg of 40wt% potassium-type stabilized sil...

Embodiment 2

[0034] Dissolve 5kg iron powder and 200g copper powder in 85L 60wt% nitric acid solution, and dilute to obtain a metal solution, in which the Fe content is 40g / L, and the Cu content is 1.6g / L; 2 CO 3 The aqueous solution was added to the reaction kettle and heated to 85°C; at the same time, the above-mentioned metal solution was also heated to 85°C, added to the reaction kettle under rapid stirring, the reaction time was 15 minutes, the pH value of the slurry was 6.0, and the precipitation was obtained by filtration and washing. The filter cake is precipitated. The co-precipitation filter cake was added with deionized water to form a slurry, and then 1.5 kg of potassium silicate water glass solution (SiO 2 : 26.5wt%, K 2 O: 13.5 wt %), mixed uniformly to obtain a co-precipitated filter cake. 1.35 kg of 30 wt % potassium stabilized silica gel and 0.125 kg of diatomaceous earth were mixed to form a mixed slurry. The mixed slurry was added to the co-precipitation filter cake,...

Embodiment 3

[0036] Prepare a metal solution with ferric nitrate and copper nitrate, wherein the Fe content is 50g / L, and the Cu content is 3.0g / L; 1.2mol / LNa 2 CO 3 The aqueous solution was added to the reaction kettle and heated to 50°C; meanwhile, the above-mentioned metal solution was also heated to 50°C, added to the reaction kettle under rapid stirring, the reaction time was 60 minutes, the pH value of the slurry was 8.0, and the coprecipitation was obtained by filtration and washing. filter cake. The co-precipitation filter cake is added deionized water to beating again, and then 6.5kg of potassium silicate water glass solution (SiO 2 : 27.0wt%, K 2 O: 13.0 wt%), mix well, adjust the pH of the slurry with nitric acid to 7.4, react at 50° C. for 20 minutes, and filter to obtain a filter cake. The filter cake was reslurried to obtain a coprecipitated filter cake. 0.55 kg of montmorillonite was added to 11.0 kg of 30 wt % potassium stabilized silica gel to form a mixed slurry. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com