A modular farmland drainage cascade purification total nitrogen removal system and method thereof

A purification system and farmland drainage technology, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of lack of pertinence in total nitrogen removal, large area of constructed wetland, High operating costs and other issues, to optimize the population structure of denitrifying bacteria, improve denitrification effect, low investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

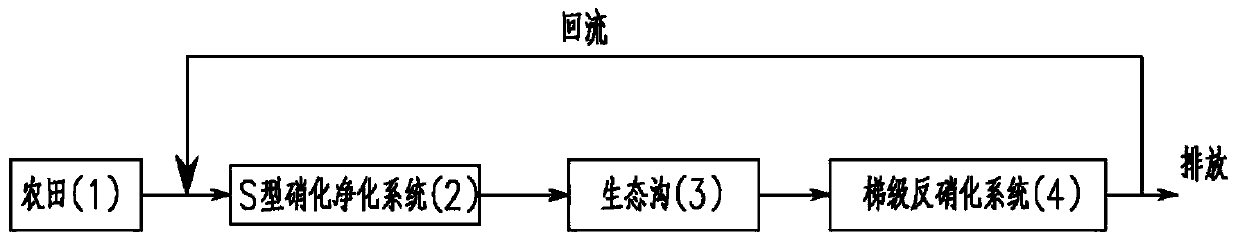

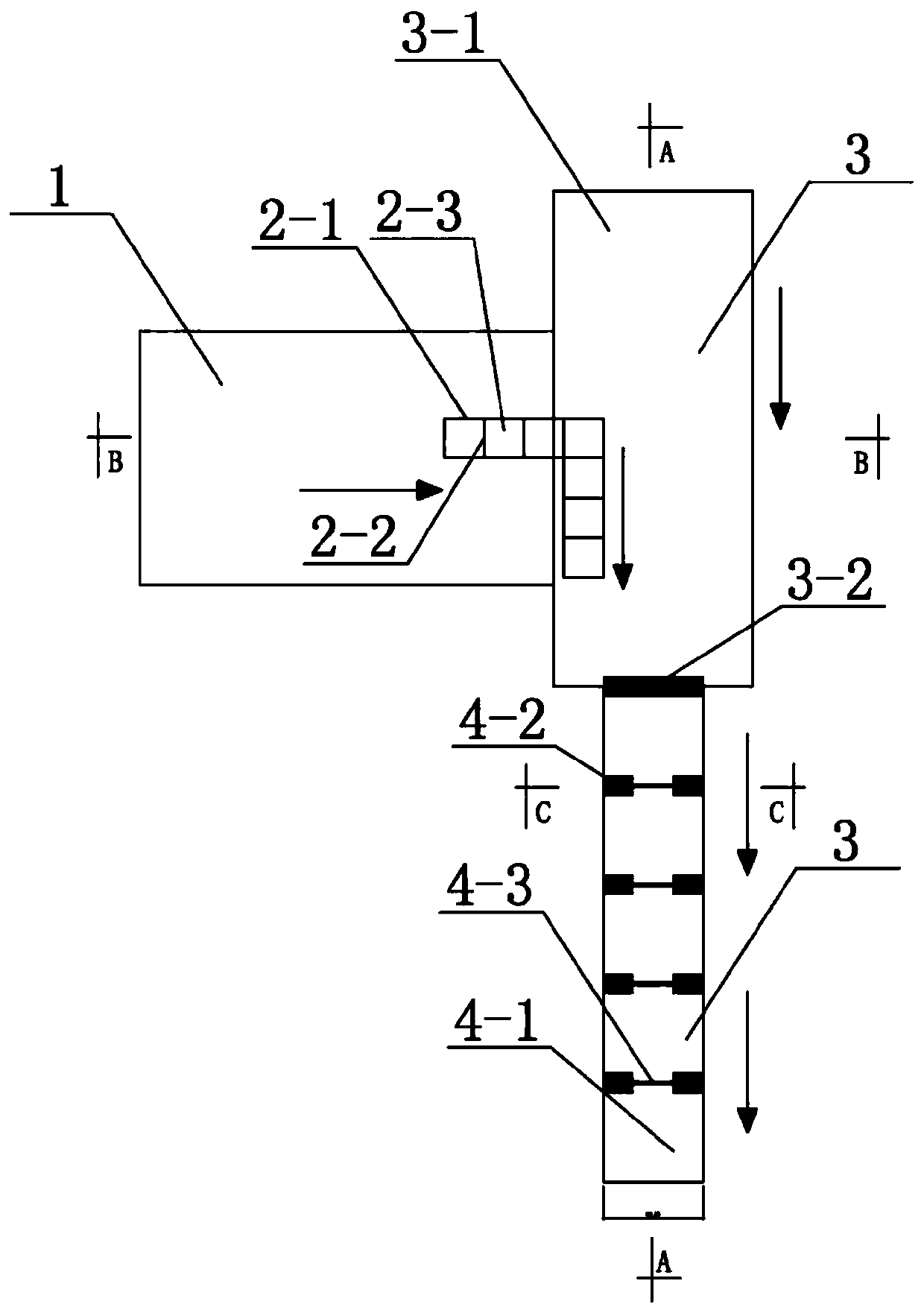

[0040] refer to Figure 1-5 , a modular farmland drainage cascade purification total nitrogen removal system, comprising a farmland 1, an S-type modular denitrification purification system 2, an ecological ditch 3 and a cascade nitrification purification system 4 connected in sequence.

[0041] The S-type modular denitrification purification system 2 includes a side baffle 2-1, a middle partition 2-2, and a denitrification purification area 2-3; the side baffle 2-1 encloses an S-shaped modular denitrification purification system , multiple intermediate partitions 2-2 divide the S-type module denitrification purification system into multiple denitrification purification zones 2-3. The section of the S-type module denitrification purification system is "L"-shaped (including two parts perpendicular to the farmland direction and along the water flow direction), arranged in steps according to the water flow direction, and descending in turn. The total length is 6-8m, of which the ...

Embodiment 2

[0066] Others are the same as embodiment 1.

[0067] 25mg / L≤TN<35mg / L, using S-type modular denitrification purification system 2, a total of 2 groups; the water quality before and after treatment is shown in Table 2.

[0068] Table 2 embodiment 2 water quality situation before and after treatment

[0069] index pH Total nitrogen content TN(mg / L) NH 3 -N (mg / L)

Embodiment 3

[0071] Others are the same as embodiment 1.

[0072] 35mg / L≤TN<40mg / L, using S-type modular denitrification purification system 2, a total of 3 groups; the water quality before and after treatment is shown in Table 3.

[0073] Table 3 embodiment 3 water quality situation before and after treatment

[0074]

[0075]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com