Treatment technology for strengthening dehydration performance of printing and dyeing sludge through hydrothermal carbonization

A treatment process, printing and dyeing sludge technology, applied in the field of resources and environment, can solve problems such as Maillard phenomenon, affecting sludge dewatering performance, etc., achieve the effect of low price, low equipment requirements, and reduce moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

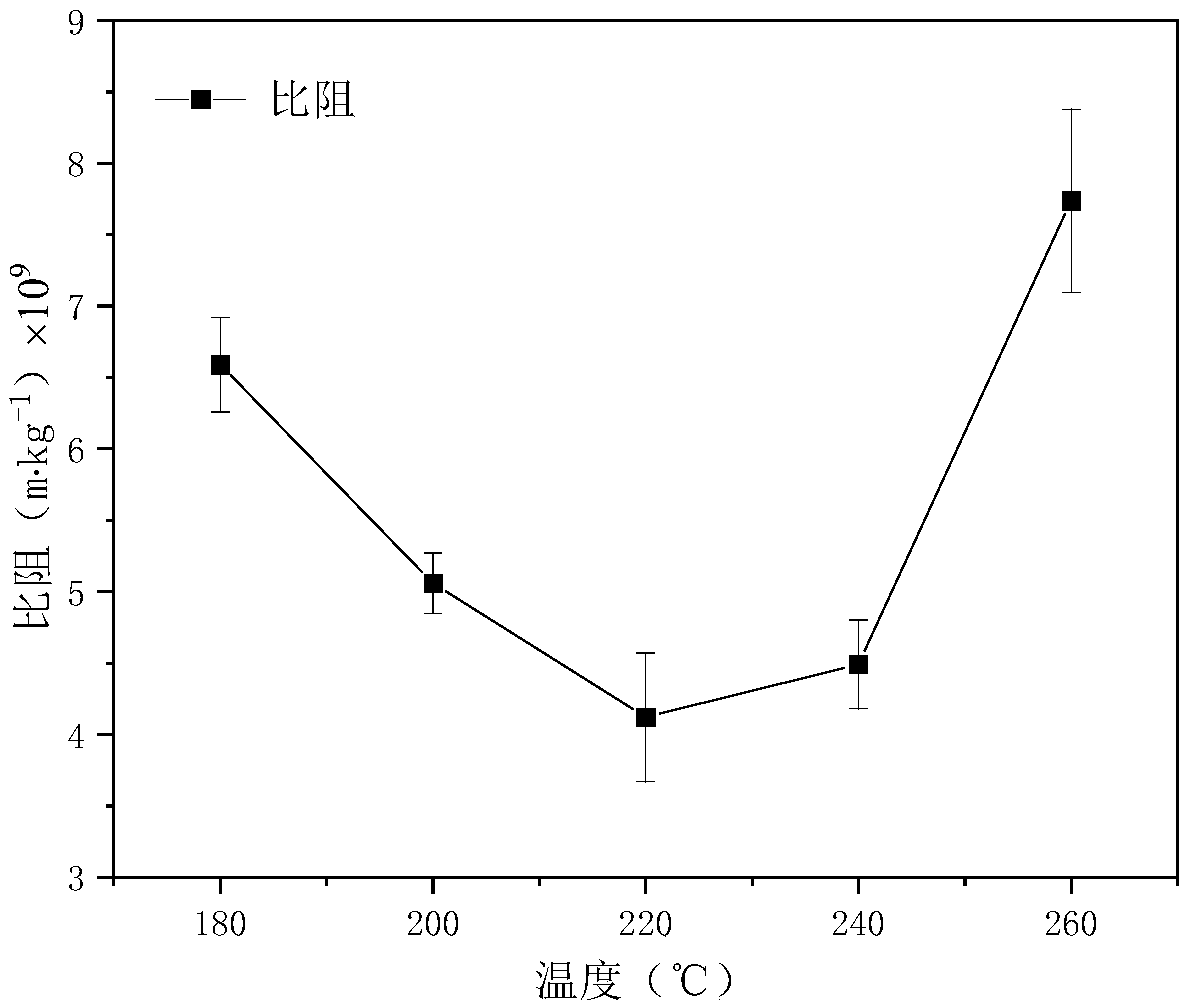

[0034] In the hydrothermal reactor, the solid content is 17.29%, and the CST, viscosity and SRF are 274s, 2850mPa·s and

[0035] 5.89×10 10 m·kg -1 The printed and dyed sludge was added with ferric sulfate and mixed evenly. The amount of ferric sulfate added was 0.2 based on the weight of solids in the sludge. Stir at 160rpm for 15 minutes, and nitrogen was introduced for 5 minutes to discharge the air. The hydrothermal temperature is controlled at 220°C, 200-240r / min stirring and reacting, after the reaction time is 120min, the activated sludge is discharged from the reactor, and input into a plate and frame filter press (BAMA 0.6 / 315-UBK type) for press filtration, the obtained sludge The moisture content of the mud is 50.4%. CST decreased from 274s to 55s; viscosity decreased from 2850mPa·s to 64mPa·s; SRF5.89×10 10 by m·kg -1 Reduced to 4.12×

[0036] 10 9 m·kg -1 . The dehydration performance is greatly improved.

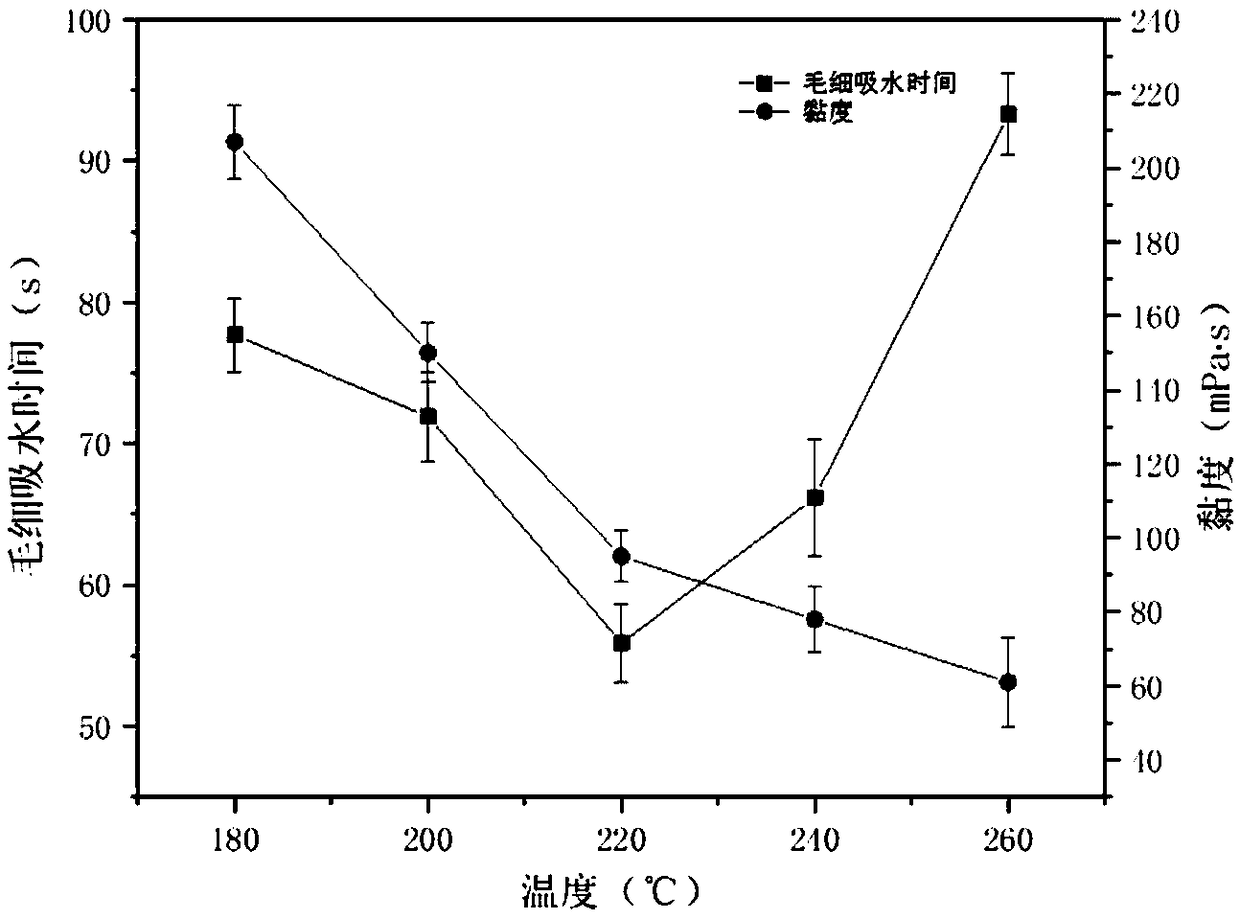

[0037] The method is the same as above, and the hy...

Embodiment 2

[0039] Same as Example 1, the solid content rate is 15.77%, CST, viscosity and SRF are 60s, 2697mPa·s and 5.59×10 respectively 10 m·kg -1 For the printing and dyeing sludge, ferric sulfate was added. The amount of ferric sulfate was 0.25 based on the weight of solids in the sludge. The hydrothermal temperature was controlled at 210°C. The stirring reaction was uniform. The sludge is discharged from the reaction kettle and input into a plate and frame filter press (BAMA 0.6 / 315-UBK type) for pressure filtration, and the moisture content of the obtained sludge is 55.2%. CST decreased from 260s to 42s; viscosity decreased from 2697mPa·s to 71mPa·s; SRF decreased from 5.59×10 10 m·kg -1 Reduced to 3.51×109m·kg-1.

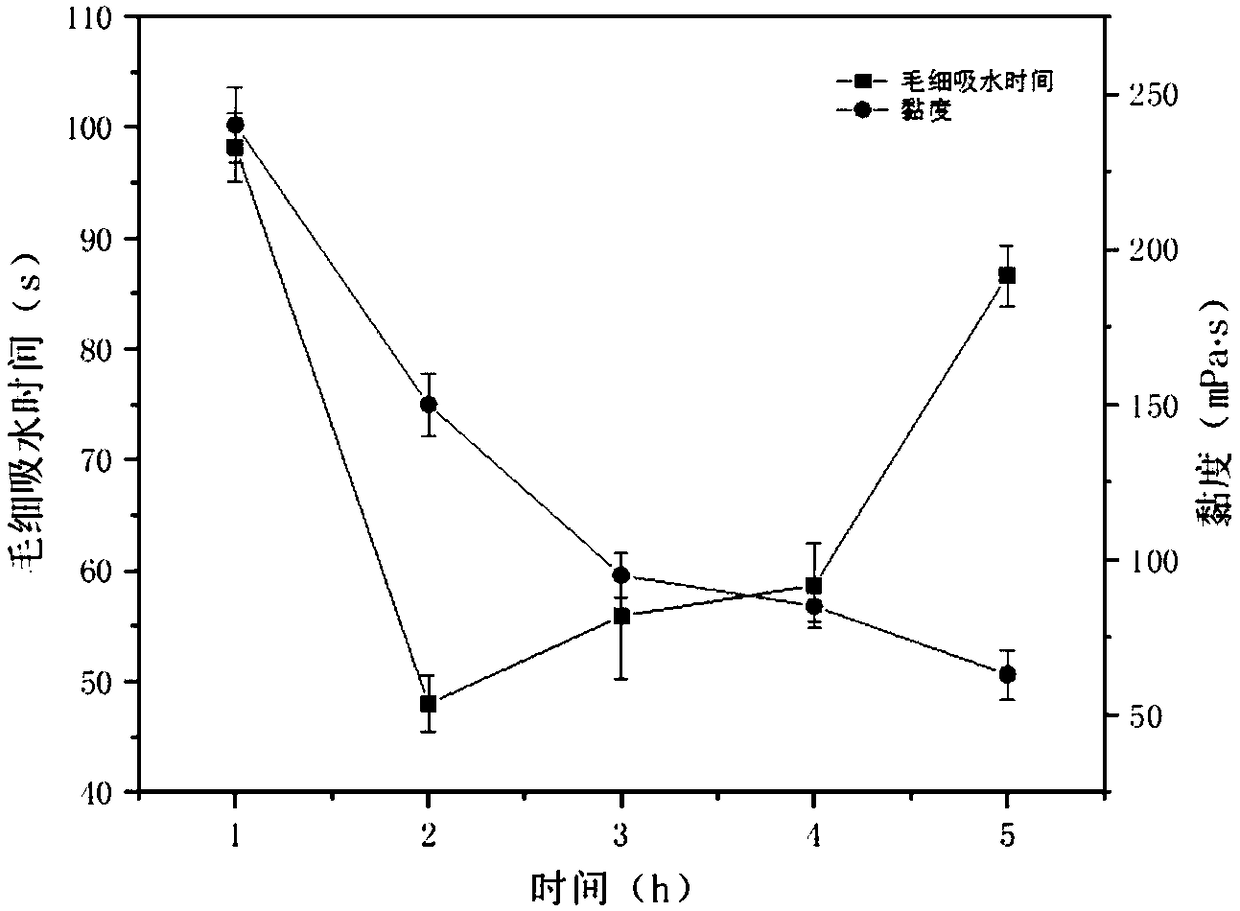

[0040] The method is the same as above, and the hydrothermal reaction time is changed between 60 and 300 minutes. image 3 and Figure 4 It reflects the change of its basic index with the reaction time. It can be seen that after 120 minutes of hydrothermal reactio...

Embodiment 3

[0042] Same as Example 1, the solid content rate is 16.13%, and the CST, viscosity and SRF are 286s, 2127mPa·s and 5.49×10 respectively 10 m·kg -1 For the printing and dyeing sludge, ferric sulfate was added. The amount of ferric sulfate was 0.5 based on the weight of the solids in the sludge. The mud is discharged from the reaction kettle, and is input into a plate and frame filter press (BAMA 0.6 / 315-UBK type) for pressure filtration, and the moisture content of the obtained sludge is 48.6%. CST decreased from 286s to 37s; viscosity decreased from 2127mPa·s to 31mPa·s; SRF decreased from 5.49×10 10 m·kg -1 Reduced to 1.46×10 9 m·kg -1 . The dehydration performance is greatly improved.

[0043] The method is the same as above, changing the dosage of the agent ferric sulfate, the mass part of the solid in the sludge is 1, and the dosage of the agent is 0, 0.1, 0.2, 0.5, 1.0 respectively. Depend on Figure 5 and Figure 6 It reflects the change of its basic index with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com