A kind of high-efficiency composite gypsum retarder and preparation method thereof

A gypsum retarder and composite technology, which is applied in the field of high-efficiency composite gypsum retarder and its preparation, can solve the problems of poor controllability of setting time, limited retarding time, large strength loss, etc., and achieve low construction efficiency , change the coagulation mechanism, the effect of small strength loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

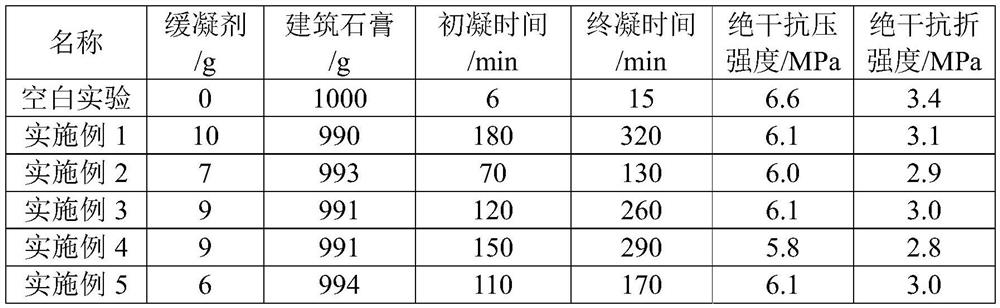

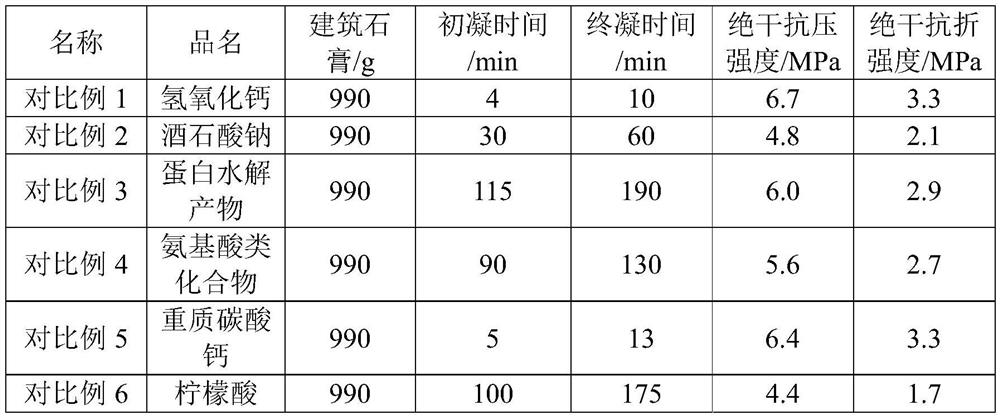

Embodiment 1

[0021] A high-efficiency composite gypsum retarder, composed of 4 parts of calcium hydroxide, 2 parts of sodium tartrate, 2 parts of protein hydrolyzate, 1 part of amino acid compounds and 1 part of heavy calcium carbonate in parts by weight. Coagulant; 990 parts of building gypsum and 10 parts of composite gypsum retarder are made into a mixture with a water-to-material ratio of 0.65, molded, and tested for setting time and strength properties.

Embodiment 2

[0023] A high-efficiency composite gypsum retarder, composed of 1 part of calcium hydroxide, 2 parts of sodium tartrate, 2 parts of protein hydrolyzate, 1 part of amino acid compounds and 1 part of heavy calcium carbonate in parts by weight. Coagulant: 993 parts of building gypsum and 7 parts of composite gypsum retarder are made into a mixture with a water-to-material ratio of 0.63, molded, and tested for setting time and strength properties.

Embodiment 3

[0025] A high-efficiency composite gypsum retarder, composed of 4 parts of calcium hydroxide, 1 part of sodium tartrate, 2 parts of protein hydrolyzate, 1 part of amino acid compounds and 1 part of heavy calcium carbonate in parts by weight. Coagulant; 991 parts of building gypsum and 9 parts of composite gypsum retarder are made into a mixture with a water-to-material ratio of 0.65, molded, and tested for setting time and strength properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com