Organic nutrient type potassium sulfate dissolution accelerator as well as preparation and application thereof

An organic nutrition, potassium sulfate technology, applied in the preparation of organic nutrition potassium sulfate dissolution accelerator, the field of organic nutrition potassium sulfate dissolution accelerator, can solve the problem of affecting fertilizer efficiency, slow dissolution speed, increase time cost, labor cost and energy cost And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

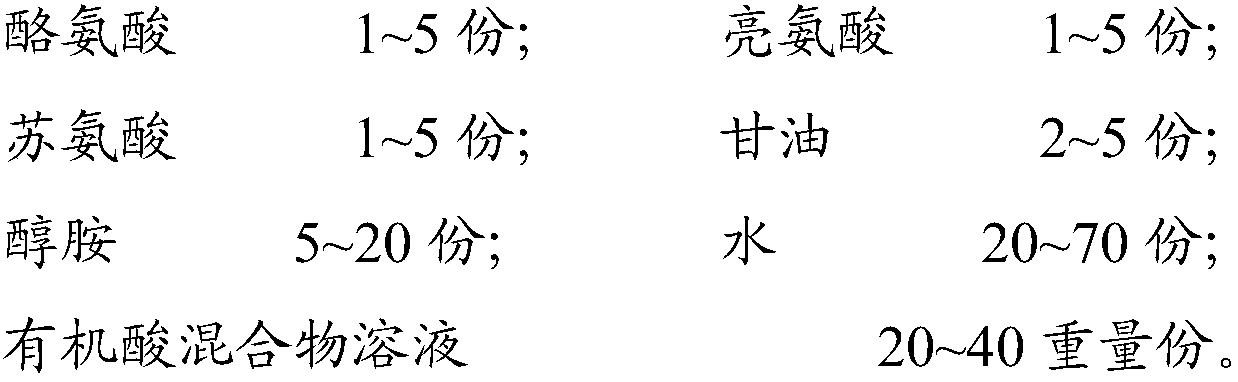

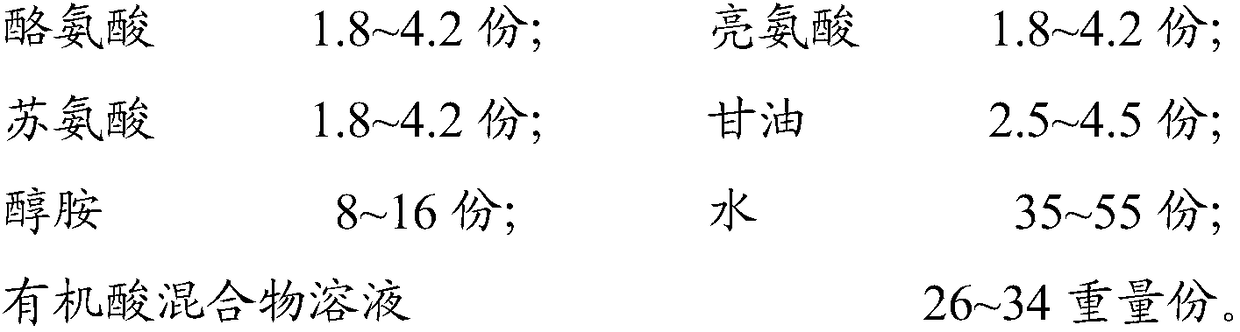

Method used

Image

Examples

Embodiment 1

[0067] Embodiment 1: preparation of organotrophic potassium sulfate dissolution accelerator of the present invention

[0068] The implementation steps of this embodiment are as follows:

[0069] A. Preparation of organic acid mixture solution

[0070] Add 20 parts by weight of glacial acetic acid, 2.8 parts by weight of salicylic acid and 1 part by weight of ethylenediaminetetraacetic acid to 72 parts by weight of a product sold by Dongying Runyi Biotechnology Co., Ltd. under the trade name wood vinegar, mix evenly, and then Heating to a temperature of 70°C, stirring at this temperature until the organic acids are completely dissolved, and then cooling to obtain the organic acid mixture solution;

[0071] B, the preparation of organotrophic potassium sulfate dissolution accelerator

[0072] Add 20 parts by weight of the organic acid mixture solution obtained in step A, 1.8 parts by weight of tyrosine, 1 part by weight of leucine, 1 part by weight of threonine and 4.5 parts b...

Embodiment 2

[0073] Embodiment 2: preparation of organotrophic potassium sulfate dissolution accelerator of the present invention

[0074] The implementation steps of this embodiment are as follows:

[0075] A. Preparation of organic acid mixture solution

[0076] Add 20 parts by weight of glacial acetic acid, 4.2 parts by weight of salicylic acid and 3 parts by weight of ethylenediaminetetraacetic acid to 74 parts by weight of the product sold by Zhengzhou Yinong Biotechnology Co., Ltd. under the trade name bamboo vinegar, mix evenly, and then Heating to a temperature of 50°C, stirring at this temperature until the organic acids are completely dissolved, and then cooling to obtain the organic acid mixture solution;

[0077] B, the preparation of organotrophic potassium sulfate dissolution accelerator

[0078] Add 26 parts by weight of the organic acid mixture solution obtained in step A, 4.2 parts by weight of tyrosine, 5 parts by weight of leucine, 1.8 parts by weight of threonine and ...

Embodiment 3

[0079] Embodiment 3: preparation of organotrophic potassium sulfate dissolution accelerator of the present invention

[0080] The implementation steps of this embodiment are as follows:

[0081] A. Preparation of organic acid mixture solution

[0082] Add 20 parts by weight of glacial acetic acid, 2 parts by weight of salicylic acid and 1.6 parts by weight of ethylenediaminetetraacetic acid to 75 parts by weight of the product sold by Jinan Kunhong Biological Company under the trade name wood vinegar, mix well, and then heat to The temperature is 60°C, stirred at this temperature until these organic acids are completely dissolved, and then cooled to obtain the organic acid mixture solution;

[0083] B, the preparation of organotrophic potassium sulfate dissolution accelerator

[0084] Add 34 parts by weight of the organic acid mixture solution obtained in step A, 1 part by weight of tyrosine, 1.8 parts by weight of leucine, 4.2 parts by weight of threonine and 2.5 parts by w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com