Preparation method of dicyclohexylcarbodiimide

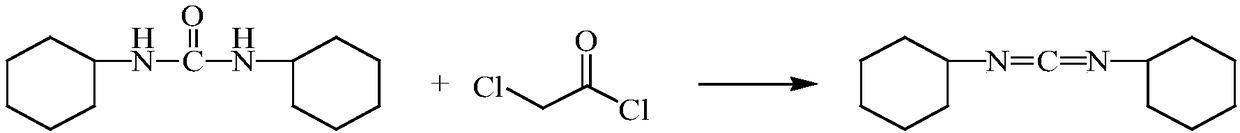

A technology of dicyclohexylcarbodiimide and dicyclohexylurea, which is applied in the field of preparation of dicyclohexylcarbodiimide, can solve the problems of unstable industrial production, large potential safety hazards, etc., and achieves improved stability and product yield. efficiency, easy operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Put 50g of DCU, 300mL of dichloromethane, and 0.1g of pyridine into a dry 500mL three-necked flask, stir evenly, dissolve 37.8g of chloroacetyl chloride in 100mL of dichloromethane and add it dropwise to the three-necked flask, and control the dropping time to 3h. The dropwise addition temperature is 5-10°C. After the dropwise addition, raise the temperature to 60°C and keep stirring for 5 hours. After the reaction, pass through ammonia gas to adjust the pH to neutral, and then filter with suction. Distilled under reduced pressure at a pressure of 1.54KPa, collected fractions at 153-156°C, and vacuum-dried to obtain the product with a purity of 97.1% and a yield of 92.8%.

Embodiment 2

[0024] Put 50g of DCU, 300mL of acetonitrile, and 0.15g of pyrrole into a dry 500mL three-necked flask, stir evenly, dissolve 37.8g of chloroacetyl chloride in 100mL of acetonitrile, and drop them into the three-necked flask. The dropping time is controlled to be 3 hours, and the dropping temperature is 5-10°C, after the dropwise addition, raise the temperature to 60°C and keep stirring for 5 hours. After the reaction, pass through ammonia gas to adjust the pH to neutral, and then filter with suction. Distill under reduced pressure, collect fractions at 153-156°C, and vacuum dry to obtain the product with a purity of 92.7% and a yield of 85.4%.

Embodiment 3

[0026] Put 50g of DCU, 300mL of acetone, and 0.15g of pyridine into a dry 500mL three-necked flask, stir evenly, dissolve 37.8g of chloroacetyl chloride in 100mL of acetone, and drop them into the three-necked flask. The dropping time is controlled to be 3 hours, and the dropping temperature is 5-10°C, after the dropwise addition, raise the temperature to 60°C and keep stirring for 5 hours. After the reaction, pass through ammonia gas to adjust the pH to neutral, and then filter with suction. Distill under reduced pressure, collect fractions at 153-156°C, and vacuum dry to obtain the product with a purity of 93.2% and a yield of 90.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com