Synthetic method of ultra-high molecular weight polyethylene

A technology of ultra-high molecular weight and synthesis method, applied in the field of synthesis of ultra-high molecular weight polyethylene, can solve the problems of complex preparation process of catalysts and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

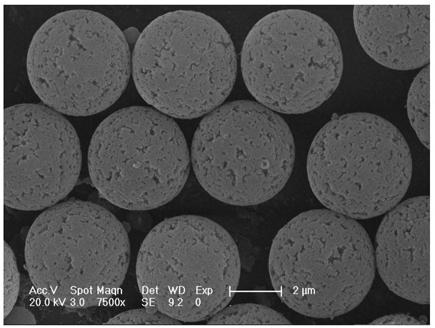

[0026] Embodiment 1 prepares supported catalyst

[0027] Under anhydrous and oxygen-free conditions, add 2 mL of methylmagnesium chloride Grignard reagent to 0.5 g of the carrier, stir for 2 hours and then filter for the first time, wash the filter cake with toluene three times, and then mix with 2 mL of TiCl 4 After mixing and stirring for 2 hours, a second filtration was performed, and the filter cake was dried to obtain 1.2 g of supported catalyst.

Embodiment 2

[0028] Embodiment 2 catalytic ethylene polymerization

[0029] In a 1L stainless steel autoclave, add 35 mg of supported catalyst, 600 ml of n-hexane solvent, and add triisobutylaluminum (TIBA) according to the Al / Ti molar ratio of 100, at a polymerization temperature of 50 ° C, under 5 atmospheres of ethylene , reacted for 30 minutes, and the viscosity average molecular weight of the obtained polyethylene was 2.28 million.

Embodiment 3

[0030] Embodiment 3 catalytic ethylene polymerization

[0031] In a 1L stainless steel autoclave, add 33 mg of supported catalyst, 600 ml of n-hexane solvent, and add triisobutylaluminum (TIBA) according to the Al / Ti molar ratio of 100. , reacted for 30 minutes, and the viscosity-average molecular weight of the obtained polyethylene was 1.71 million.

PUM

| Property | Measurement | Unit |

|---|---|---|

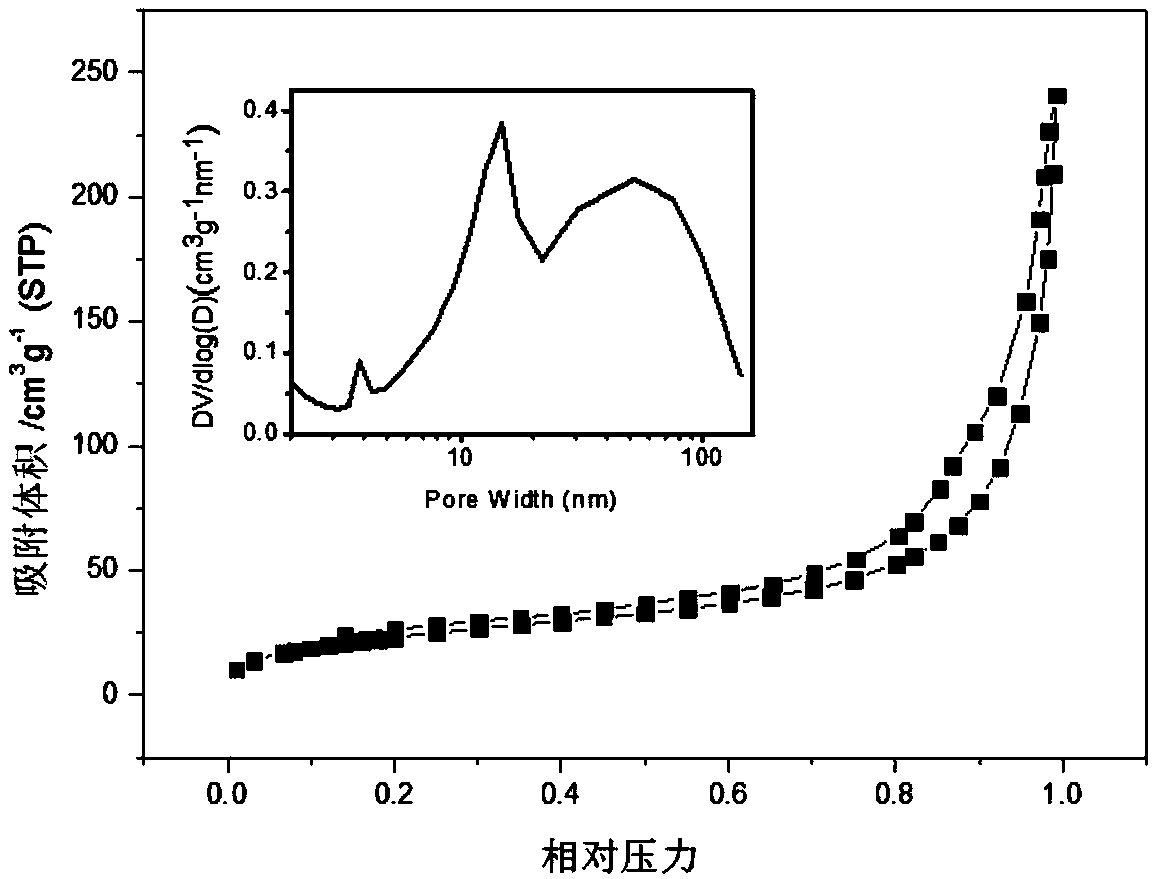

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com