Mxene/PNIPAM/alginate composite thermal response hydrogel as well as preparation and application thereof

An alginate and hydrogel technology, applied in functional hydrogel materials and their preparation and application fields, can solve the problems of poor mechanical properties of PNIPAM hydrogels, and achieve excellent thermal response performance, strong bio-friendliness, high The effect of infrared absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

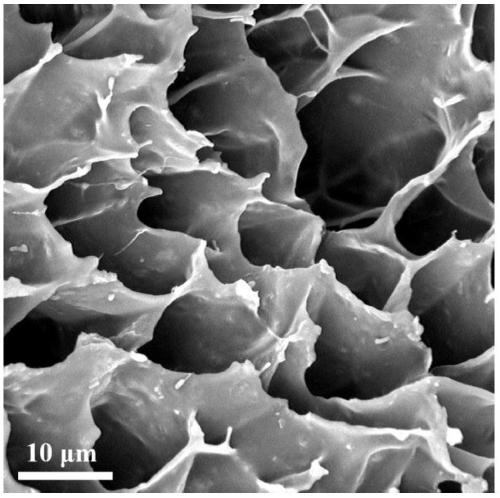

[0032] (1) Using deionized water as a solvent, add components in the following proportions: the NIPAM monomer mass is 20% of the deionized water quality, the MXene quality is 1% of the NIPAM quality, and the sodium alginate quality is 1% of the NIPAM quality, The quality of the crosslinking agent (N, N-methylenebisacrylamide) is 0.1% of the quality of NIPAM, the quality of the initiator (ammonium persulfate) is 1% of the quality of NIPAM, and the quality of the accelerator (tetramethylethylenediamine) is 1% of NIPAM mass to obtain a composite solution.

[0033] (2) Pour the composite solution in step (1) into a glass mold with a cavity thickness of 0.5 mm for in-situ polymerization and solidification molding at a temperature of 10° C. for 48 hours. The hydrogel was taken out from the mold, put into a 1% calcium chloride solution for post-treatment for 48 hours at a temperature of 10°C, and then placed in deionized water for 48 hours at a temperature of 10°C. The obtained comp...

Embodiment 2

[0039] (1) Using deionized water as a solvent, add components in the following proportions: the NIPAM monomer mass is 15% of the deionized water quality, the MXene quality is 3% of the NIPAM quality, and the sodium alginate quality is 1.5% of the NIPAM quality, The quality of the crosslinking agent (N, N-methylenebisacrylamide) is 0.3% of the quality of NIPAM, the quality of the initiator (ammonium persulfate) is 1% of the quality of NIPAM, and the quality of the accelerator (tetramethylethylenediamine) is 1% of NIPAM mass to obtain a composite solution.

[0040] (2) Pour the composite solution in step (1) into a glass mold with a cavity thickness of 1 mm for in-situ polymerization and solidification molding at a temperature of 20° C. for 36 hours. The hydrogel was taken out from the mold, put into a 3% calcium chloride solution for post-treatment for 36 hours at a temperature of 20°C, and then placed in deionized water for 36 hours at a temperature of 20°C. The obtained comp...

Embodiment 3

[0042] (1) Using deionized water as a solvent, add components in the following proportions: the NIPAM monomer mass is 10% of the deionized water quality, the MXene quality is 5% of the NIPAM quality, and the sodium alginate quality is 2% of the NIPAM quality, The quality of the crosslinking agent (N, N-methylenebisacrylamide) is 0.5% of the quality of NIPAM, the quality of the initiator (ammonium persulfate) is 1% of the quality of NIPAM, and the quality of the accelerator (tetramethylethylenediamine) is 1% of NIPAM mass to obtain a composite solution.

[0043] (2) Pour the composite solution in step (1) into a glass mold with a cavity thickness of 2 mm for in-situ polymerization and solidification molding at a temperature of 30° C. for 24 hours. The hydrogel was taken out from the mold, put into a 5% calcium chloride solution for post-treatment for 24 hours at a temperature of 30°C, and then placed in deionized water for 48 hours at a temperature of 30°C. The obtained compos...

PUM

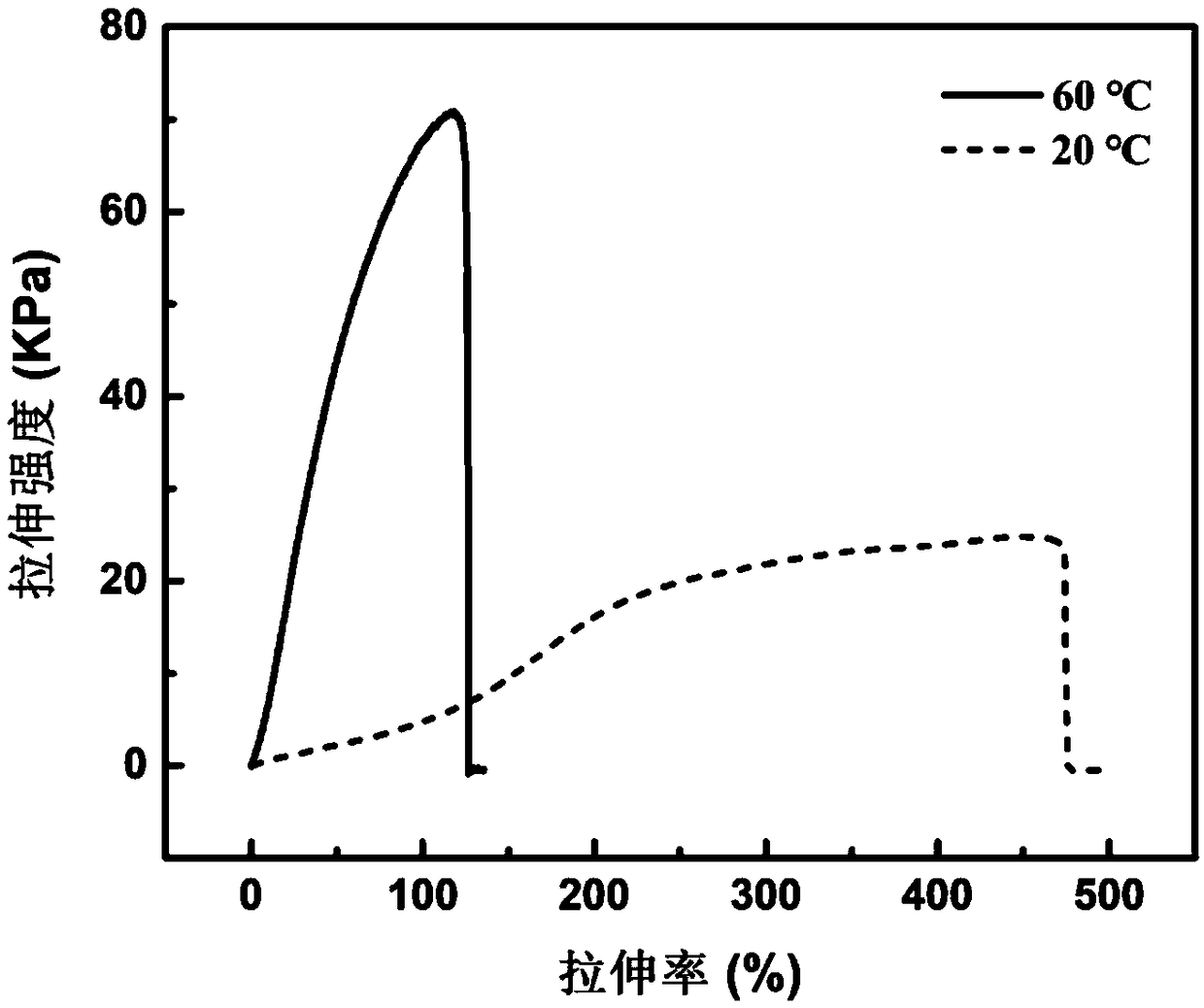

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com