A method for the construction of intelligent reversible self-assembled structures based on core-shell phase-change cellulose nanocrystals under solid-state conditions

A nanocrystalline and cellulose technology, applied in the field of self-assembly of nanomaterials, to achieve excellent self-healing and thermal reversible properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0044] Specific Embodiment 1: In this embodiment, a method for constructing an intelligent reversible self-assembled structure based on core-shell phase-change cellulose nanocrystals under solid-state conditions is carried out in the following steps:

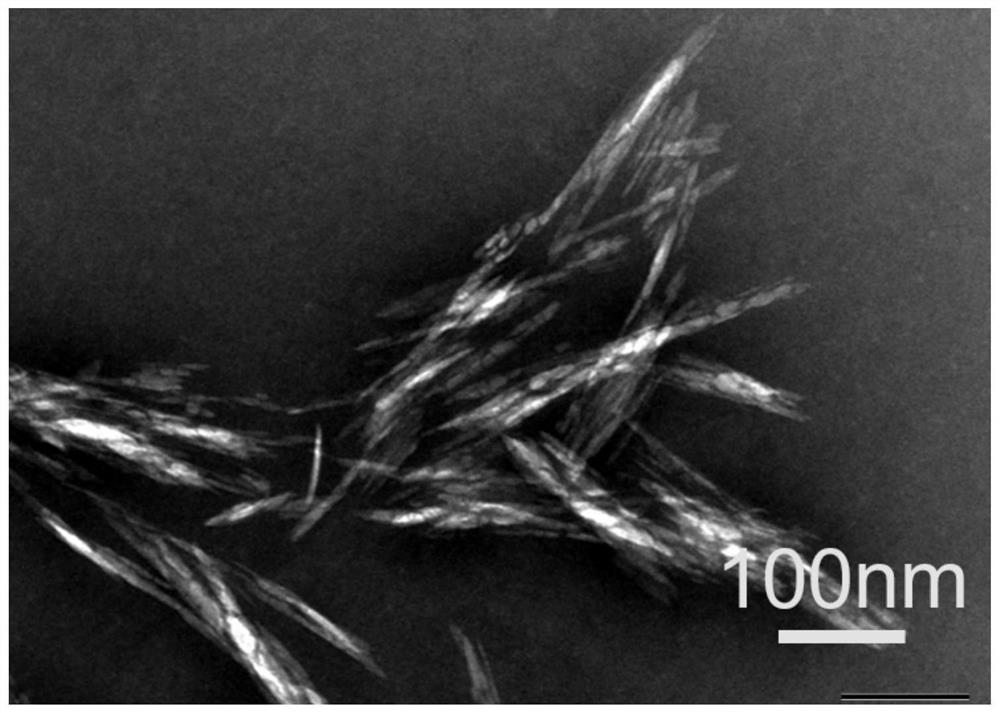

[0045] 1. Preparation of cellulose nanocrystals:

[0046] ①. Add microcrystalline cellulose to aqueous hydrochloric acid solution with a concentration of 5mol / L-8mol / L to obtain suspension A. Under the condition of a power of 60W-120W, ultrasonicate the suspension A in an ice-water bath for 10min-20min , and then stand at room temperature for 15h to 20h to obtain the mixture;

[0047] The volume ratio of the quality of the microcrystalline cellulose to the hydrochloric acid aqueous solution whose concentration is 5mol / L~8mol / L is 1g:(30~40)mL;

[0048] ②. Under the conditions of magnetic stirring speed of 200r / min-500r / min and temperature of 90℃-100℃, reflux the mixture for 3h-4h, and then naturally cool to room temperature to ...

specific Embodiment approach 2

[0076] Embodiment 2: This embodiment differs from Embodiment 1 in that the unsaturated fatty acid chloride described in Step 2 ② is an unsaturated fatty acid chloride with an aliphatic carbon chain length of 10-13. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0077] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the long-chain alkyl mercaptan described in step 3 ① is a long-chain alkyl mercaptan with a carbon chain length of 14-22. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com