High-thermal-conductivity polymer material composite film with thermal response performance and preparation method of high-thermal-conductivity polymer material composite film

A technology of polymer materials and composite membranes, applied in chemical instruments and methods, layered products, synthetic resin layered products, etc. The effect of large tonality, improved application range and low material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

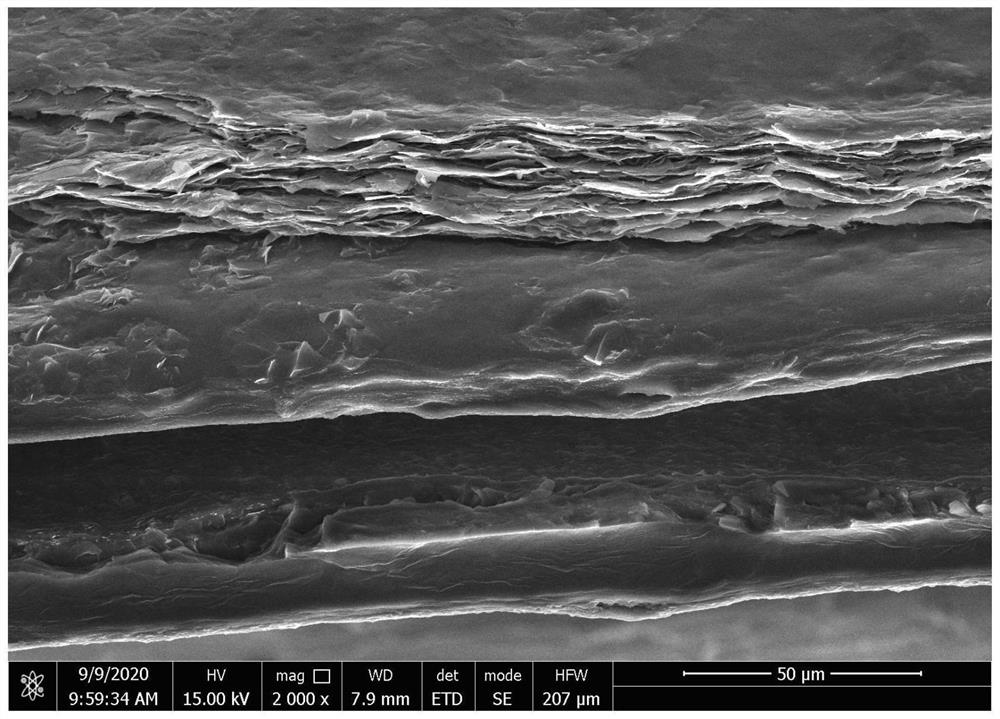

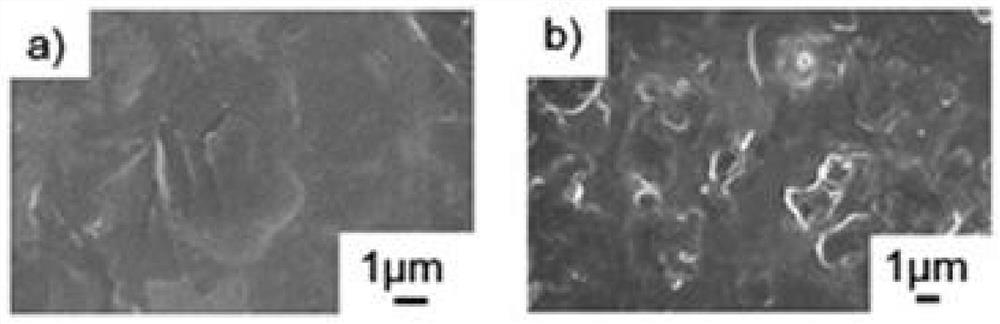

Image

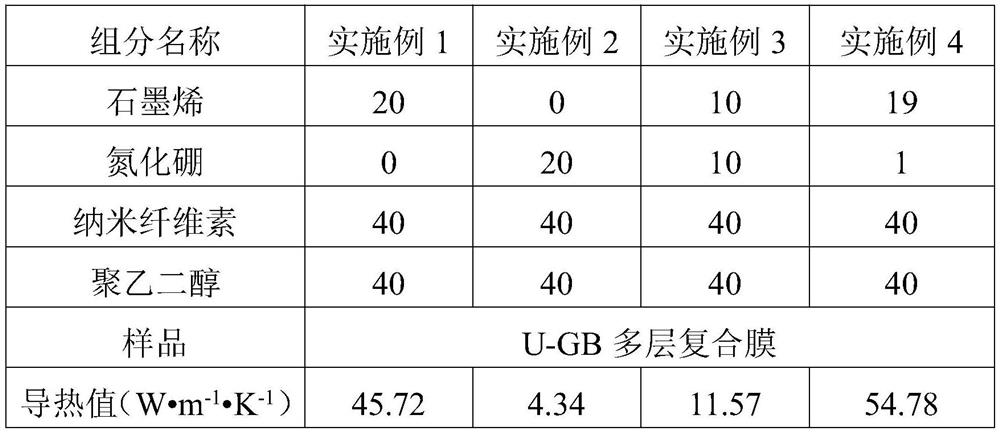

Examples

preparation example Construction

[0029] The preparation method of the high thermal conductivity polymer material composite film with thermal response performance is characterized in that it comprises the following steps:

[0030] (1) Add boron nitride, graphene, nanocellulose and polyethylene glycol into the dispersant respectively, stir for 0.5-1 hour, and sonicate for 5-10 minutes to prepare a boron nitride dispersion with a concentration of 1-5 mg / mL, Graphene dispersion, nanocellulose dispersion and polyethylene glycol dispersion;

[0031] (2) Mix the boron nitride dispersion, graphene dispersion, nanocellulose dispersion and polyethylene glycol dispersion obtained in step (1) according to the set weight ratio, stir for 0.5-1h, and ultrasonically for 5-10min , to obtain boron nitride-nanocellulose-polyethylene glycol mixed solution, graphene-nanocellulose-polyethylene glycol mixed solution and graphene / boron nitride-nanocellulose- Polyethylene glycol mixture;

[0032] (3) Mixing the nanocellulose disper...

specific Embodiment 1

[0037] The high thermal conductivity polymer material composite film with thermal response performance provided in this embodiment is a multi-layer high thermal conductivity polymer material composite film with heat-driven shape memory performance, which is composed of graphene, boron nitride, polyethylene Composed of alcohol and nanocellulose, the mass percent of graphene in the composite film is 19%, the mass percent of boron nitride is 1%, the mass percent of nanocellulose is 40%, and the mass percent of polyethylene glycol is 40%. The average horizontal size of the graphene is 10-20 microns, and the average thickness is 5-10 layers; the average size of the boron nitride is 3-5 microns. The diameter of the nanocellulose is 5-100nm, the aspect ratio is 100-1000; the molecular weight of polyethylene glycol is 10000.

[0038] The preparation method of the heat-driven shape memory multi-layer high thermal conductivity polymer material composite film provided in this embodiment ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com