Preparation method and application of controllable multi-level cross-linked injectable thermally induced phase change hydrogel

A technology of thermally induced phase change and hydrogel, which is applied in the direction of medical preparations, pharmaceutical formulas, and prostheses of non-active ingredients, which can solve the problems of poor mechanical properties of hydrogels and hinder applications, and achieve the goal of overcoming micro-gap and Poor fluidity, thermally sensitive response, and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

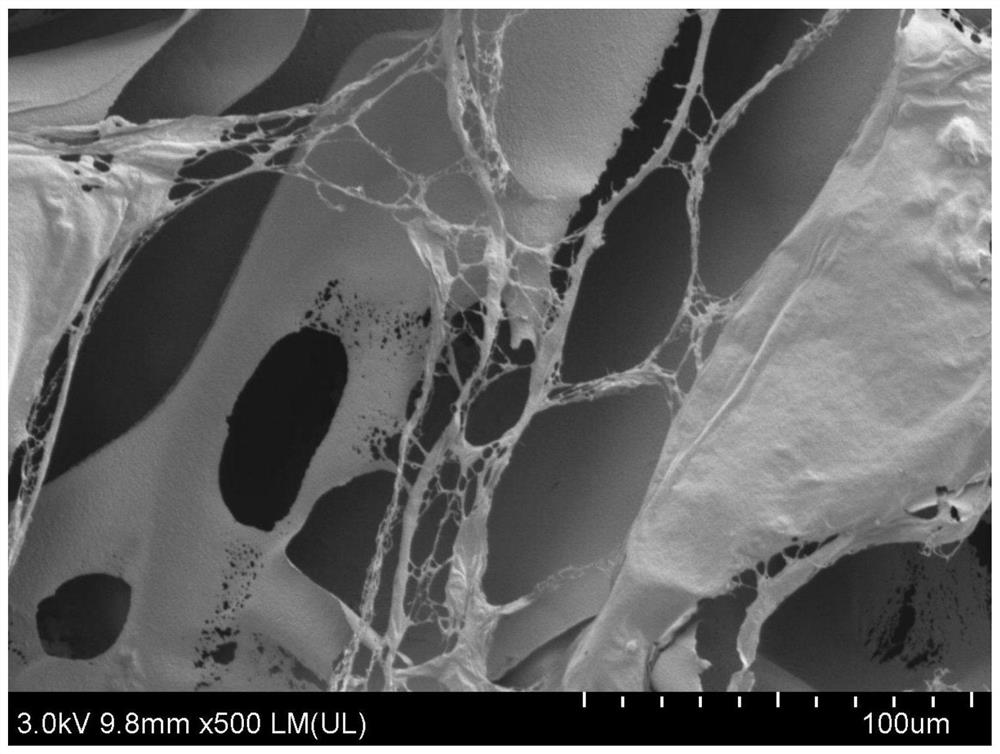

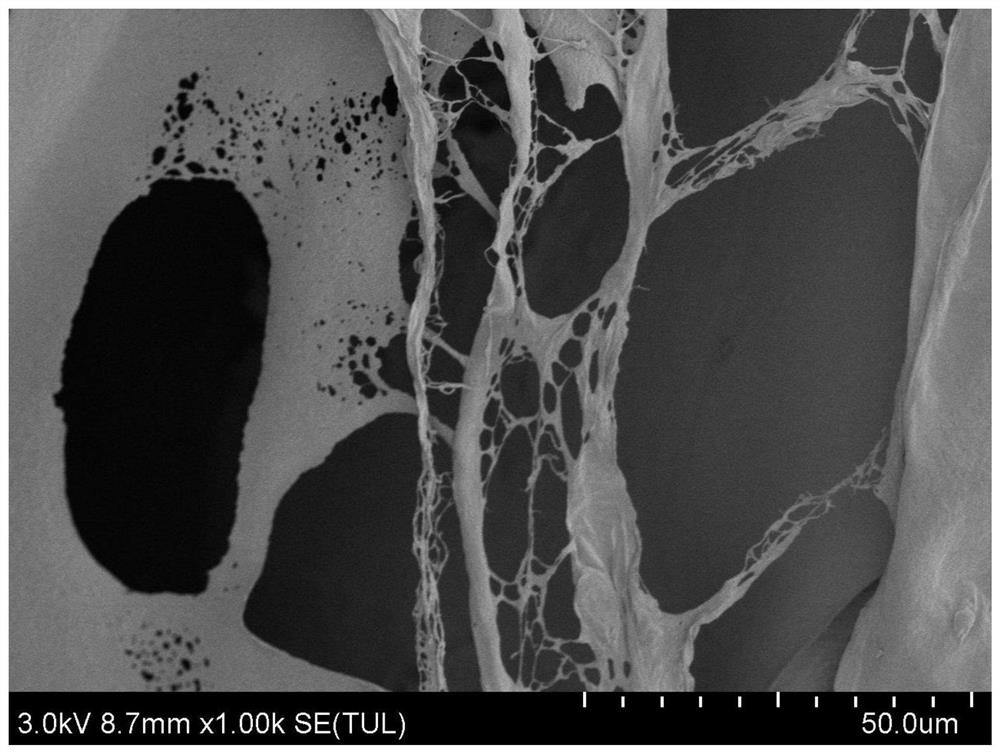

Image

Examples

example 1

[0038] Step 1: Dispersion of chitosan and its derivatives and preconditioning of reaction environment

[0039] Weigh the chitosan matrix phase and dissolve it in the buffer solution at a solute ratio of 50:1. Sonicate for 10 minutes, heat and stir for 1 hour to fully disperse in the solution.

[0040] Step 2: Nucleophilic Substitution of Matrix Phase

[0041] Add 10% amine salts to the uniformly dispersed composite hot solution as a reaction aid. Sonicate for 10 minutes, heat and stir to make it fully dissolved, keep stirring after 1 hour and slowly add 20% polyamine compound, speed up the speed, after the compound is fully dissolved, add acetic acid solution drop by drop, and use a pH meter to detect until The pH of the solution is adjusted to be weakly acidic, heated and stirred for 6 hours, and the multi-activation group amino group is grafted to the branch chain on the sixth or third carbon of the chitosan molecule through a nucleophilic substitution process.

[0042] S...

example 2

[0053] Example 2: Step 1: Preconditioning of the reaction environment and nucleophilic substitution of the matrix phase

[0054] Step 1: Dispersion of chitosan and its derivatives and preconditioning of reaction environment

[0055] Weigh the chitosan matrix phase and dissolve it in the buffer solution at a solute ratio of 50:1. Sonicate for 20 minutes, heat and stir for 2 hours to fully disperse in the solution.

[0056] Step 2: Nucleophilic Substitution of Matrix Phase

[0057] Add 2% amine salts to the uniformly dispersed composite hot solution as a reaction aid. Sonicate for 30 minutes, heat and stir to make it fully dissolved, keep stirring after 2 hours and slowly add 50% polyol compound, etc., speed up the speed, after the compound is fully dissolved, add acetic acid solution drop by drop, and use an acidity meter to detect, Until the pH of the solution is adjusted to be weakly acidic, heat and stir for 3 hours, and through a nucleophilic substitution process, multip...

example 3

[0070] Step 1: Dispersion of chitosan and its derivatives and preconditioning of reaction environment

[0071] A pH buffer solution of a certain concentration is prepared, and the chitosan matrix phase with a solute ratio of 50:1 is weighed and dissolved in the buffer solution. Sonicate for 20 minutes, heat and stir for 2 hours to fully disperse in the solution.

[0072] Step 2: Nucleophilic Substitution of Matrix Phase

[0073] Add 5% amine salts to the uniformly dispersed composite hot solution as a reaction aid. Sonicate for 30 minutes, heat and stir to make it fully dissolved, keep stirring after 2 hours and slowly add 20% polyamine compound, etc., speed up the speed, after the compound is fully dissolved, add acetic acid solution drop by drop, and use an acidity meter to detect, Until the pH of the solution is adjusted to be weakly acidic, heat and stir for 3 hours, and multiple activated groups such as amino groups are grafted to the branched chain on the sixth or thir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com