Methionine-intercalated magnalium hydrotalcite nanocontainer and preparation method thereof

A technology of magnesium aluminum hydrotalcite and methionine, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve difficult problems such as methionine intercalation, and achieve operability Strong, environment-friendly and low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

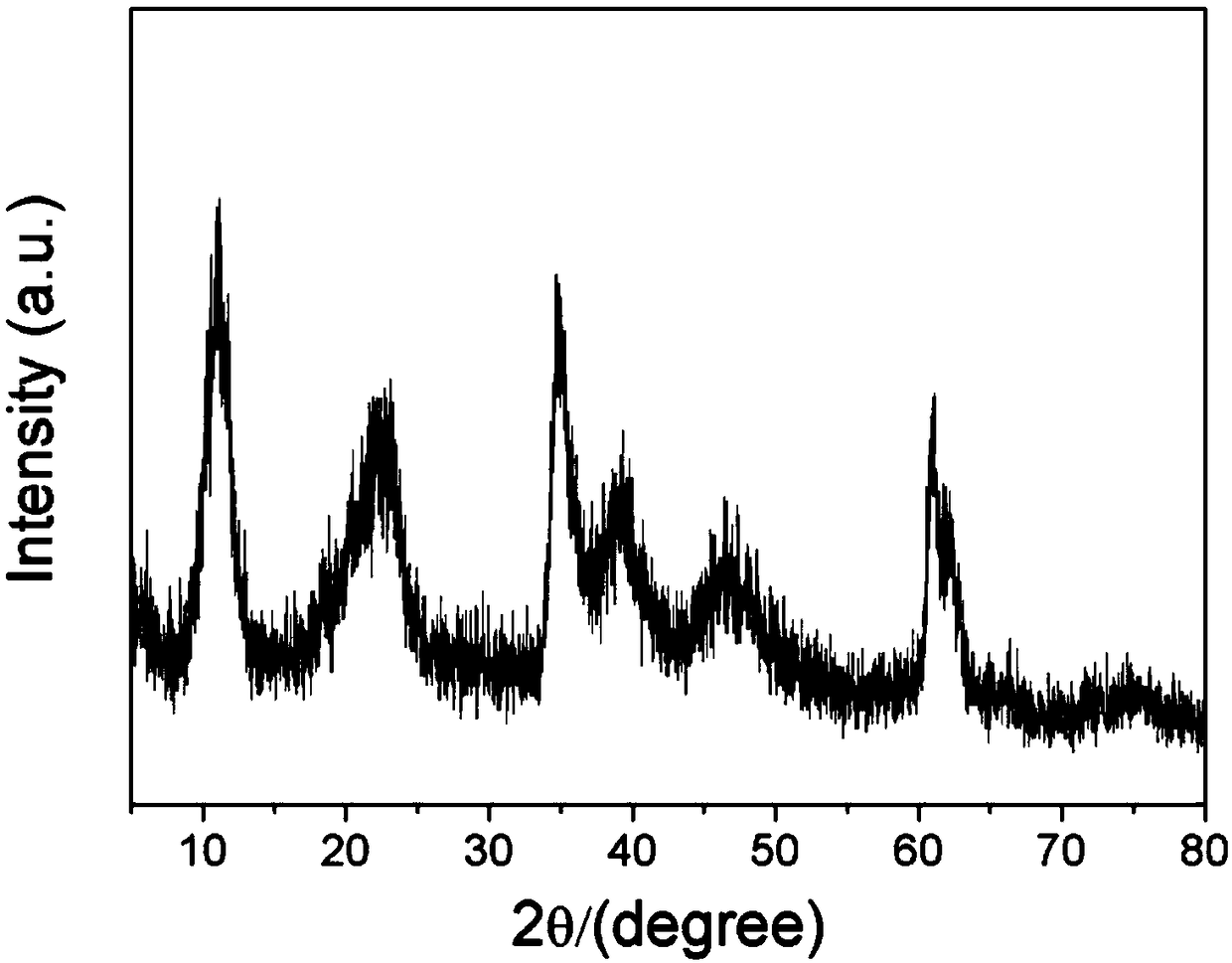

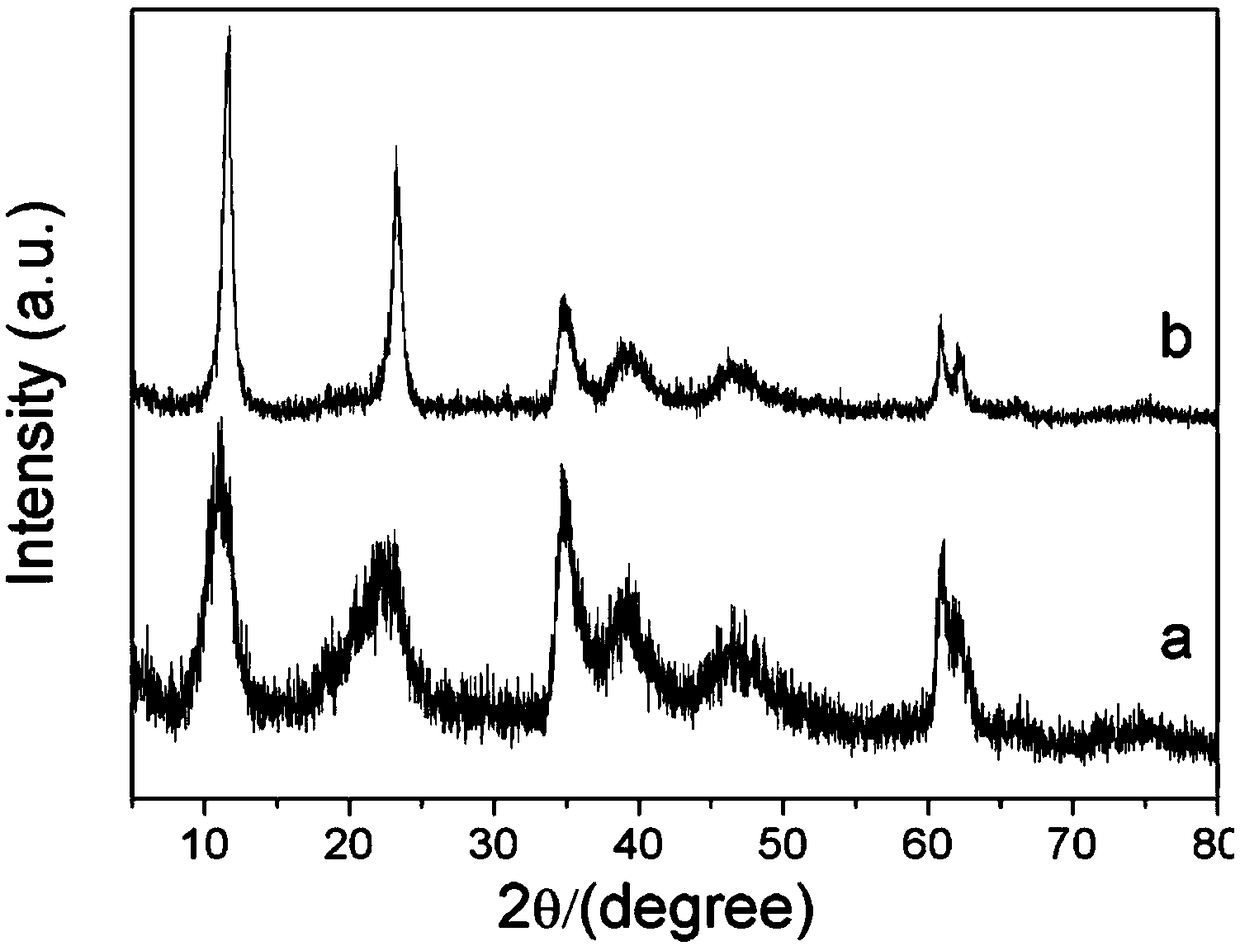

Embodiment 1

[0050] (1) Mg(NO 3 ) 2 ·6H 2 O and Al(NO 3 ) 3 9H 2 O according to n(Mg 2+ ) / n(Al 3+ )=2:1 uniformly dispersed in deionized water to form solution A. Dissolve NaOH in deionized water to make a NaOH solution with a NaOH concentration of 1 mol / L to form solution B.

[0051] (2) Dilute methionine according to methionine and Mg(NO 3 ) 2 ·6H 2 O molar ratio 2:5 was weighed and uniformly dispersed in deionized water, adjusted to pH 8.5-9.0 with NaOH to form solution C.

[0052] (3) Transfer solution C to a four-neck flask, put it into a water bath, keep the temperature at 30 degrees Celsius under the condition of feeding nitrogen, and keep stirring, and add solution A dropwise to solution C after 1 hour, And use solution B to adjust the pH to maintain it at 8.5-9.0, and the temperature in the whole process is maintained at 30 degrees Celsius.

[0053] (4) After the dropwise addition was completed, the mixed solution was stirred for 30 minutes to complete the reaction, an...

Embodiment 2

[0055] (1) Mg(NO 3 ) 2 ·6H 2 O and Al(NO 3 ) 3 9H 2 O according to n(Mg 2+ ) / n(Al 3+ )=2:1 uniformly dispersed in deionized water to form solution A. Dissolve NaOH in deionized water to make a NaOH solution with a NaOH concentration of 1.5 mol / L to form solution B.

[0056] (2) Dilute methionine according to methionine and Mg(NO 3 ) 2 ·6H 2 O molar ratio 2:5 was weighed and uniformly dispersed in deionized water, adjusted to pH 9.0-9.5 with NaOH to form solution C.

[0057] (3) Transfer solution C to a four-neck flask, put it into a water bath, keep the temperature at 35 degrees Celsius under the condition of nitrogen gas and keep stirring, and add solution A dropwise to solution C after 1 hour, And use solution B to adjust the pH so that it is maintained at 9.0-9.5, and the temperature of the whole process is maintained at 35 degrees Celsius.

[0058] (4) After the dropwise addition was completed, the mixed solution was stirred for 30 minutes to complete the react...

Embodiment 3

[0060] (1) Mg(NO 3 ) 2 ·6H 2 O and Al(NO 3 ) 3 9H 2 O according to n(Mg 2+ ) / n(Al 3+ )=3:1 uniformly dispersed in deionized water to form solution A. Dissolve NaOH in deionized water to make a NaOH solution with a NaOH concentration of 1 mol / L to form solution B.

[0061] (2) Dilute methionine according to methionine and Mg(NO 3 ) 2 ·6H 2 O molar ratio 3:5 was weighed and uniformly dispersed in deionized water, adjusted to pH 8.5-9.0 with NaOH to form solution C.

[0062] (3) Transfer solution C to a four-neck flask, put it into a water bath, keep the temperature at 30 degrees Celsius under the condition of feeding nitrogen, and keep stirring, and add solution A dropwise to solution C after 1 hour, And use solution B to adjust the pH to maintain it at 8.5-9.0, and the temperature in the whole process is maintained at 30 degrees Celsius.

[0063] (4) After the dropwise addition was completed, the mixed solution was stirred for 30 minutes to complete the reaction, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com