Preparation method of antibacterial and antistatic coating

An anti-static coating and a technology for preparation steps are applied in conductive coatings, anti-fouling/underwater coatings, and biocide-containing paints, etc., and can solve the problems that it is difficult to achieve antibacterial and anti-static effects for a long time, and the anti-static coatings are easy to fall off. Achieve the effect of increasing electrical conductivity, good mechanical and electrical properties, good electrical conductivity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

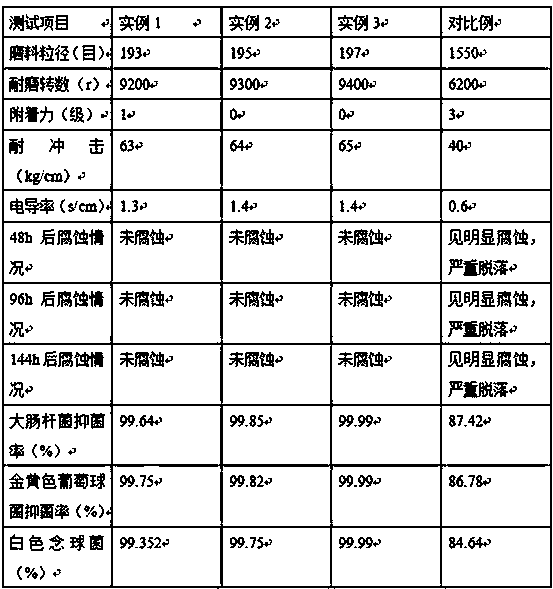

Examples

example 1

[0025] Mix montmorillonite and marble at a mass ratio of 2:3, put them into a pulverizer and pulverize for 1 hour, pass through a 150-mesh sieve after pulverization, and collect the sifted powder; According to the mass ratio of 2:1:1, the mixture is obtained and added to the fermenter, and the concentration of 7% of the mixture mass is added at the same time as 10 7 cfu / mL yeast suspension, seal the fermenter, and adjust the temperature in the fermenter to 30°C, and ferment for 2 weeks, the obtained fermentation product is the modified inorganic mineral, ready for use; Add ammonia water with a concentration of 0.8mol / L into the solution until the precipitate is completely dissolved to obtain a cuproammonia solution. The obtained cuproammonia solution is mixed at 38°C at a rate of 2mL / cm 2 Spray the cuproammonia solution onto the surface of the carbon nanotube powder. After the surface of the carbon nanotube powder is completely wetted, quickly spray the cuproammonia solution a...

example 2

[0027] Mix montmorillonite and marble at a mass ratio of 2:3, put them into a pulverizer and pulverize for 1.5 hours, pass through a 150-mesh sieve after pulverization, and collect the sifted powder; The sugar is mixed according to the mass ratio of 2:1:1 to obtain the mixture and added to the fermenter. At the same time, the concentration of 8% of the mass of the mixture is 10 7 cfu / mL yeast suspension, seal the fermenter, and adjust the temperature in the fermenter to 35°C, and ferment for 2 weeks, the obtained fermentation product is the modified inorganic mineral, ready for use; Add ammonia water with a concentration of 0.8mol / L to the solution until the precipitate is completely dissolved to obtain a cuproammonia solution. The obtained cuproammonia solution is heated at 39°C at a rate of 2mL / cm 2Spray the cuproammonia solution onto the surface of the carbon nanotube powder. After the surface of the carbon nanotube powder is completely wetted, quickly spray the cuproammoni...

example 3

[0029] Mix montmorillonite and marble at a mass ratio of 2:3, put them into a pulverizer and pulverize them for 2 hours, pass through a 150-mesh sieve after pulverization, and collect the sifted powder; According to the mass ratio of 2:1:1, the mixture is obtained and added to the fermenter, and the concentration of 10% of the mass of the mixture is added at the same time as 10 7 cfu / mL yeast suspension, seal the fermenter, and adjust the temperature in the fermenter to 40°C, and ferment for 3 weeks, the obtained fermentation product is the modified inorganic mineral, ready for use; Add ammonia water with a concentration of 0.8mol / L into the solution until the precipitate is completely dissolved to obtain a cuproammonia solution. The obtained cuproammonia solution is mixed at 40°C at a rate of 3mL / cm 2 Spray the cuproammonia solution onto the surface of the carbon nanotube powder, after the surface of the carbon nanotube powder is completely wetted, quickly spray it with 3mL / c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com