Lubricant prepared from nanomaterials and preparation method thereof

A technology of nanomaterials and lubricants, applied in the direction of mixing methods, lubricating compositions, chemical instruments and methods, etc., can solve the problem that lubricants do not have anti-oxidation and stability properties, extend the shelf life of base oil, and cannot reduce energy consumption, etc. problems, achieve good oxidation resistance and stability, good anti-wear extreme pressure, and reduce wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

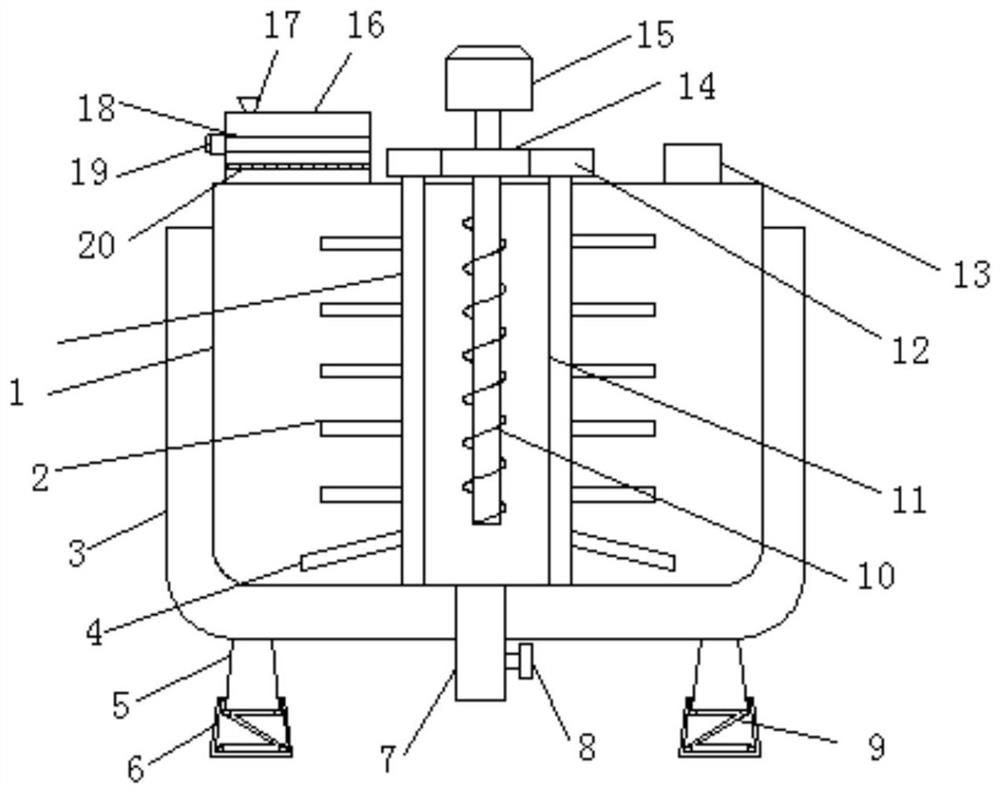

Method used

Image

Examples

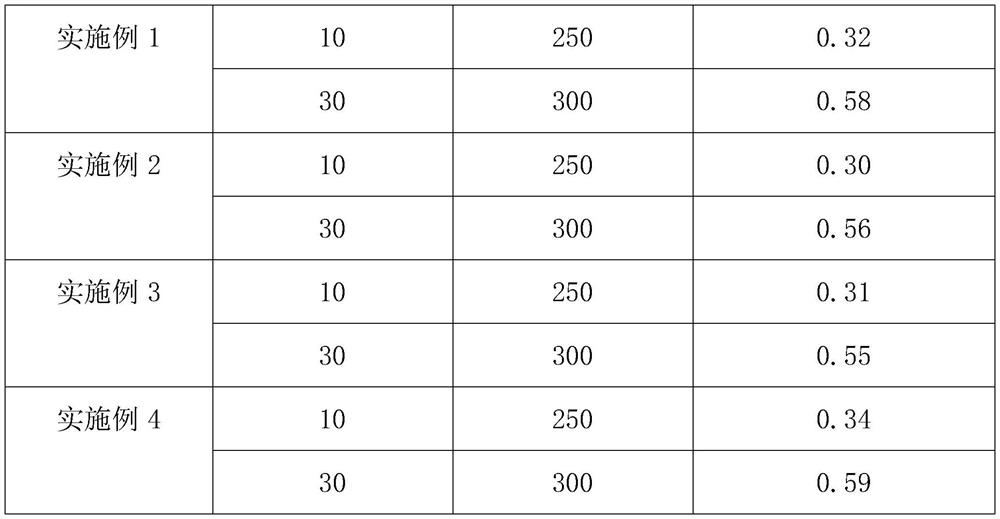

Embodiment 1

[0032] A lubricant prepared from nanomaterials, the raw materials are 20 parts by weight of nanoparticles, 45 parts of base oil, 1 part of rust remover, 3 parts of modified anti-wear extreme pressure agent and 2 parts of modified surface modifier;

[0033] Among them, the parts by weight of the raw materials in the modified anti-wear extreme pressure agent are 15 parts of diisotridecylamine, 17 parts of molybdenum oxide, 1 part of sodium benzoate, 3 parts of emulsified silicone oil and isopropyl-α-methylbenzene Propionaldehyde 1 part;

[0034] The preparation method of the modified antiwear extreme pressure agent comprises the following steps:

[0035] 1) Add diisotridecylamine, molybdenum oxide and sodium benzoate into the reaction container in sequence, stir evenly for 2-3 hours, and react to prepare the molybdenum amine complex precursor, wash the precursor with alcohol, and dry for 30 minutes; then Add a certain amount of water solvent to the precursor, then stir for 1 ho...

Embodiment 2

[0045] A lubricant prepared from nanomaterials, the raw materials are 25 parts by weight of nanoparticles, 50 parts of base oil, 5 parts of rust remover, 8 parts of modified anti-wear extreme pressure agent and 7 parts of modified surface modifier;

[0046] Among them, the parts by weight of the raw materials in the modified anti-wear extreme pressure agent are 20 parts of diisotridecylamine, 20 parts of molybdenum oxide, 2 parts of sodium benzoate, 5 parts of emulsified silicone oil and isopropyl-α-methylbenzene 5 parts of propionaldehyde;

[0047] The preparation method of the modified antiwear extreme pressure agent comprises the following steps:

[0048] 1) Add diisotridecylamine, molybdenum oxide and sodium benzoate into the reaction vessel in turn, stir evenly for 2.5 hours, and react to prepare the molybdenum amine complex precursor, wash the precursor with alcohol, and dry for 30 minutes; Add a certain amount of water solvent to the system and then stir for 1.5 hours,...

Embodiment 3

[0058] A lubricant prepared from nanomaterials, the raw materials are 35 parts by weight of nanoparticles, 60 parts of base oil, 8 parts of rust remover, 15 parts of modified anti-wear extreme pressure agent and 11 parts of modified surface modifier;

[0059] Among them, the parts by weight of the raw materials in the modified anti-wear extreme pressure agent are 30 parts of diisotridecylamine, 25 parts of molybdenum oxide, 3 parts of sodium benzoate, 11 parts of emulsified silicone oil and isopropyl-α-methylbenzene 8 parts of propionaldehyde;

[0060] The preparation method of the modified antiwear extreme pressure agent comprises the following steps:

[0061] 1) Add diisotridecylamine, molybdenum oxide and sodium benzoate into the reaction container in turn, stir evenly for 3 hours, and react to prepare the molybdenum amine complex precursor, wash the precursor with alcohol, and dry for 30 minutes; Add a certain amount of water solvent to the system and then stir for 2 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com