Composite exterior wall panel

A technology of composite exterior wall panels and plates, applied in the field of composite exterior wall panels, can solve the problems of unfavorable stress on the main structure, high bearing capacity requirements, high quality of the overall wall panels, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

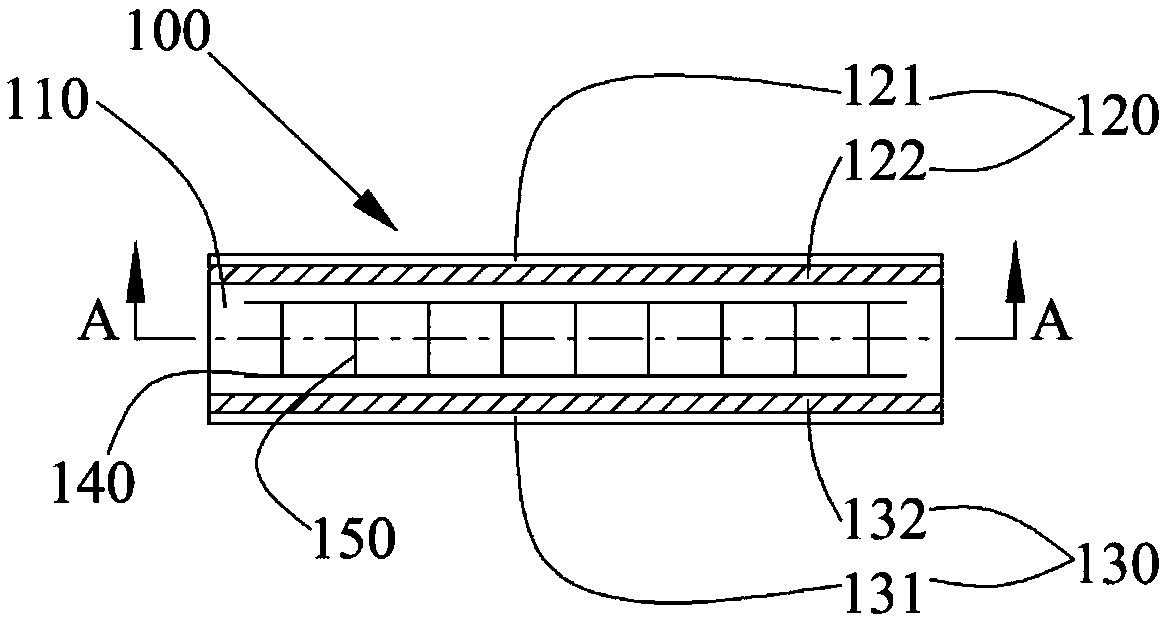

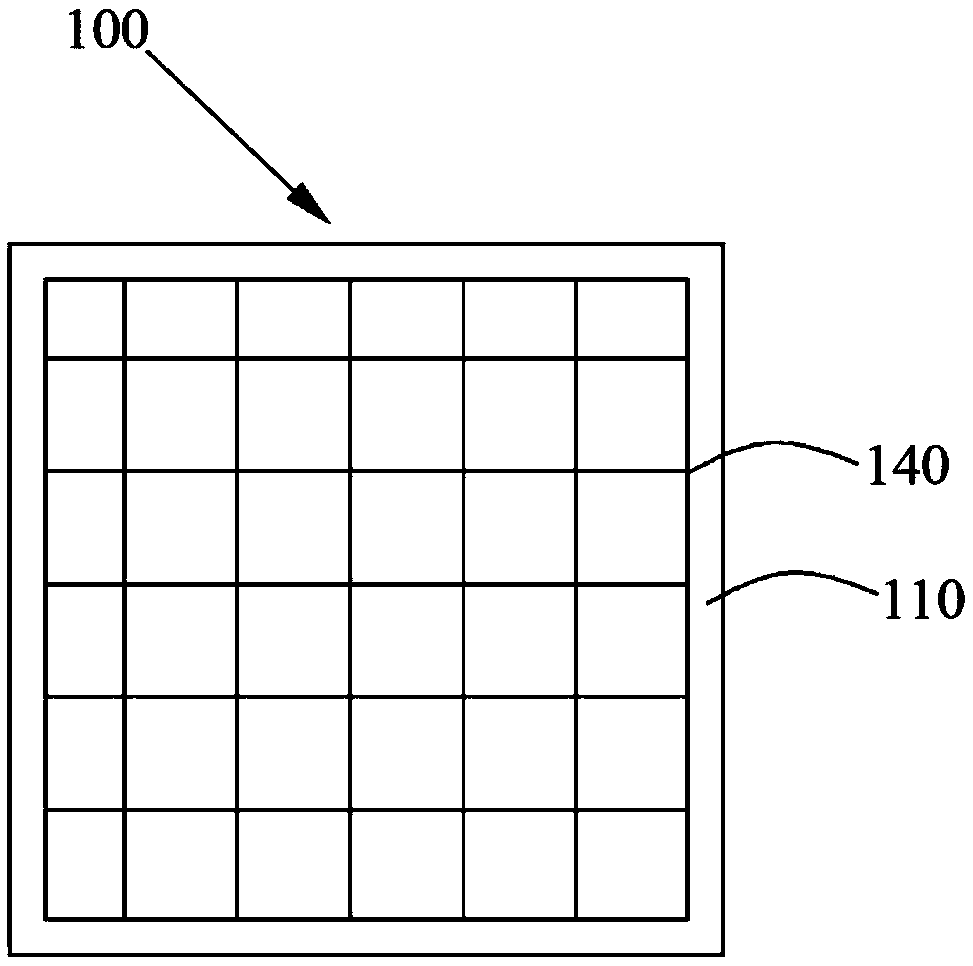

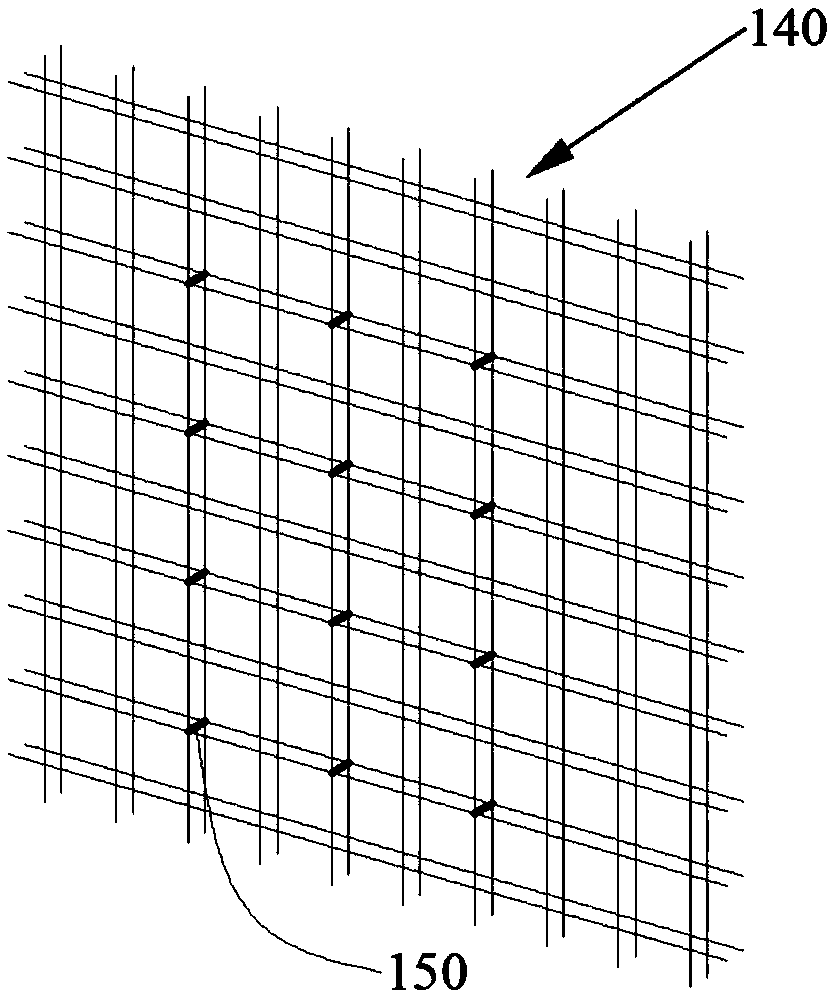

[0023] Please refer to Figure 1 to Figure 3 This embodiment 1 provides a composite exterior wall panel 100, which includes a concrete wall 110 prepared by adding heat-insulating materials to Portland cement, and an exterior decorative layer 120 adhered to the inner and outer sides of the concrete wall 110, respectively. And the interior decoration layer 130, the interior of the concrete wall 110 is provided with a double-layer two-way steel mesh 140, and the double-layer two-way steel mesh 140 includes a first layer of steel mesh and a second layer of steel mesh arranged at intervals, and is connected to the The tie bars 150 between the first layer of reinforcement mesh and the second layer of reinforcement mesh. Wherein the concrete wall body 110 can be fixedly connected with the interior and exterior decoration layers in other ways.

[0024] The composite exterior wall panel 100 provided in this embodiment 1 is manufactured by industrial production, thus forming a light-we...

Embodiment 2

[0037] The difference between the second embodiment and the first embodiment is that the material of the decorative surface 121 of the outer decorative layer and the decorative surface 131 of the inner decorative layer can be fluorocarbon paint or paint layer, and the fluorocarbon paint can be used in harsh environments. No pulverization and no falling off, waterproof and dustproof, can guarantee decoration and adhesion for a long time, and has excellent flexibility, full color and good texture.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com