Microwave sensor based on substrate integrated waveguide and microfluidic technology

A substrate-integrated waveguide and microfluidic technology, applied in the field of sensors, can solve the problems of bulky sensors, unfavorable processing and integration, etc., and achieve the effect of light and thin volume, compact structure, and chemical inert expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to better describe the design process and purpose, the present invention will be further described below in conjunction with the embodiments and accompanying drawings:

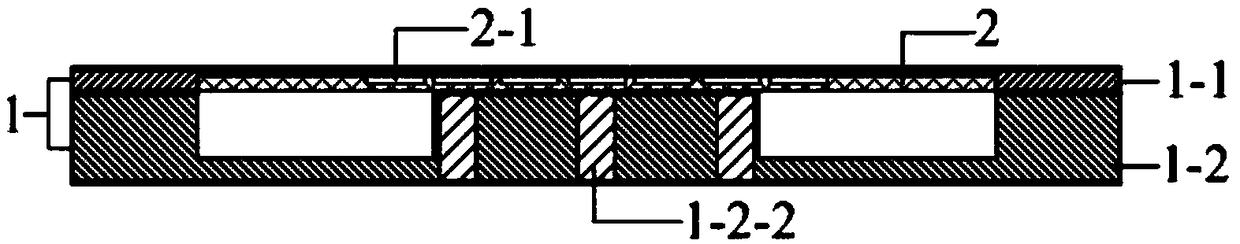

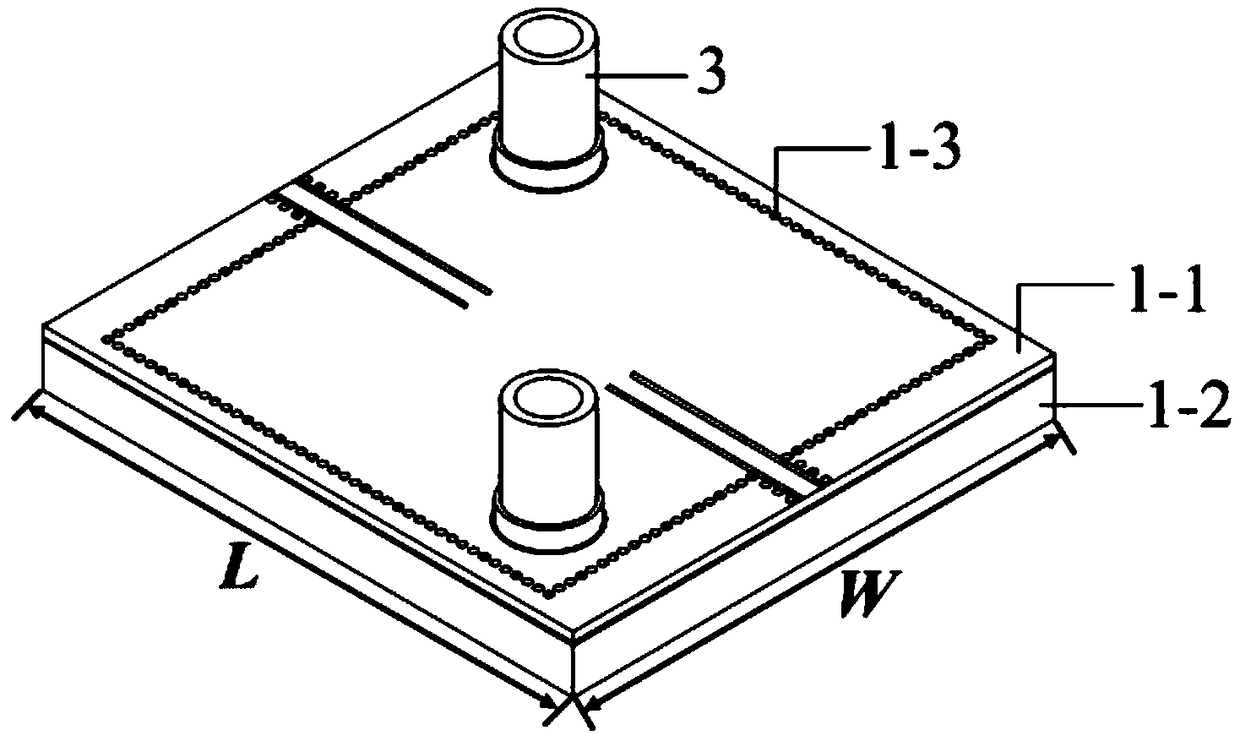

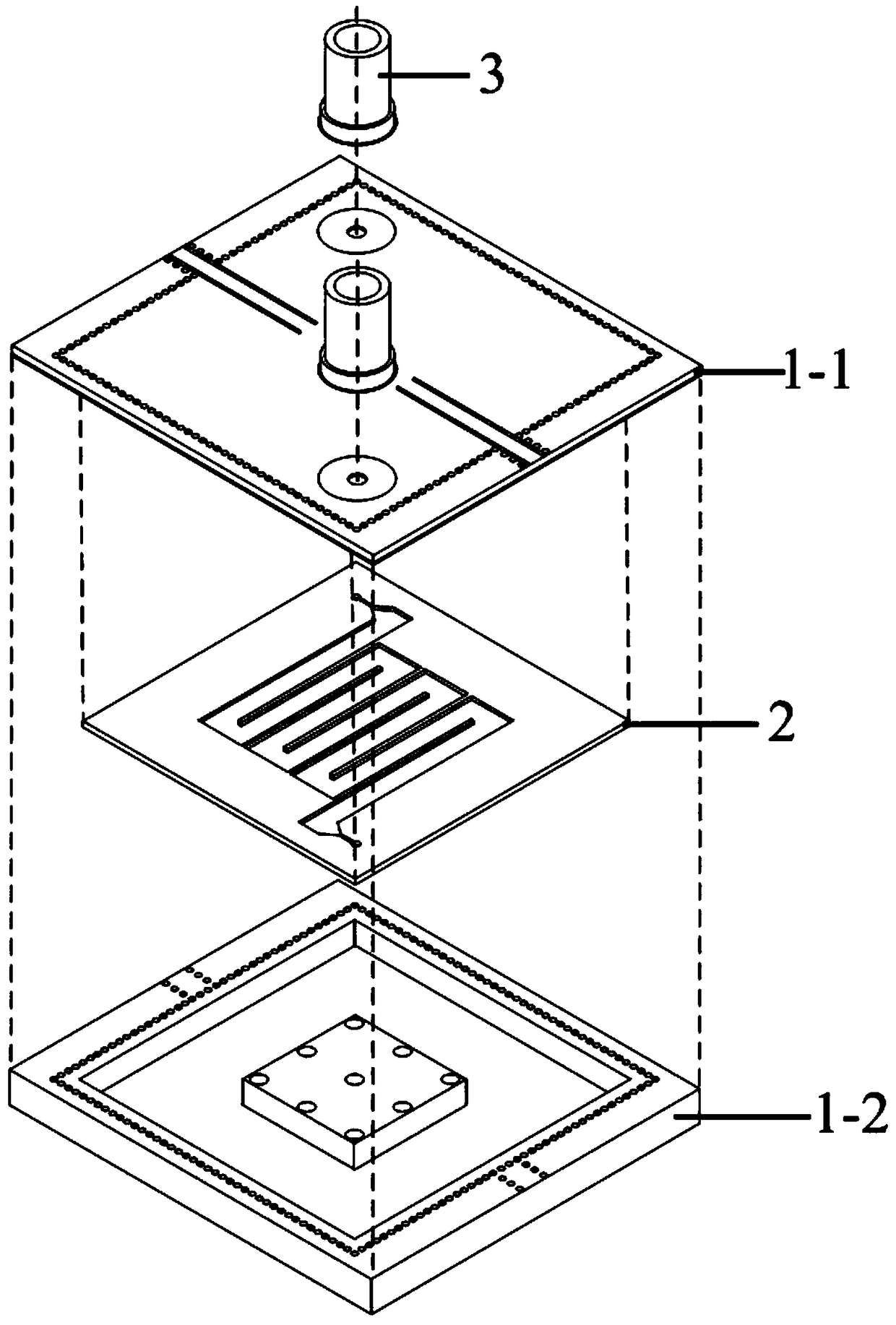

[0032] like Figure 1 to Figure 5(a) As shown in Fig. 5(b), the microwave sensor based on substrate-integrated waveguide re-entrant cavity and microfluidic technology proposed by the present invention includes a substrate-integrated waveguide re-entrant cavity 1 and a piece embedded in the cavity microfluidic chip2.

[0033] The resonant cavity 1 is composed of an upper cover plate 1-1 and a lower base 1-2. Both the upper cover plate 1-1 and the lower base 1-2 include a three-layer structure, namely a top metal layer, an intermediate dielectric layer and a bottom metal layer.

[0034] Wherein the bottom metal layer of the upper cover plate 1-1 has the same area as the top metal layer of the lower base 1-2, and the two are glued together with conductive glue.

[0035] The material of the inte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com