A dye sensitized battery electrode, a preparation method thereof and the application of MIL-47 material

A MIL-47, dye-sensitized technology, applied in the field of dye-sensitized battery electrodes and their preparation, can solve the problems of easy corrosion and high electrode cost, and achieve the effects of low cost, simple preparation process and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

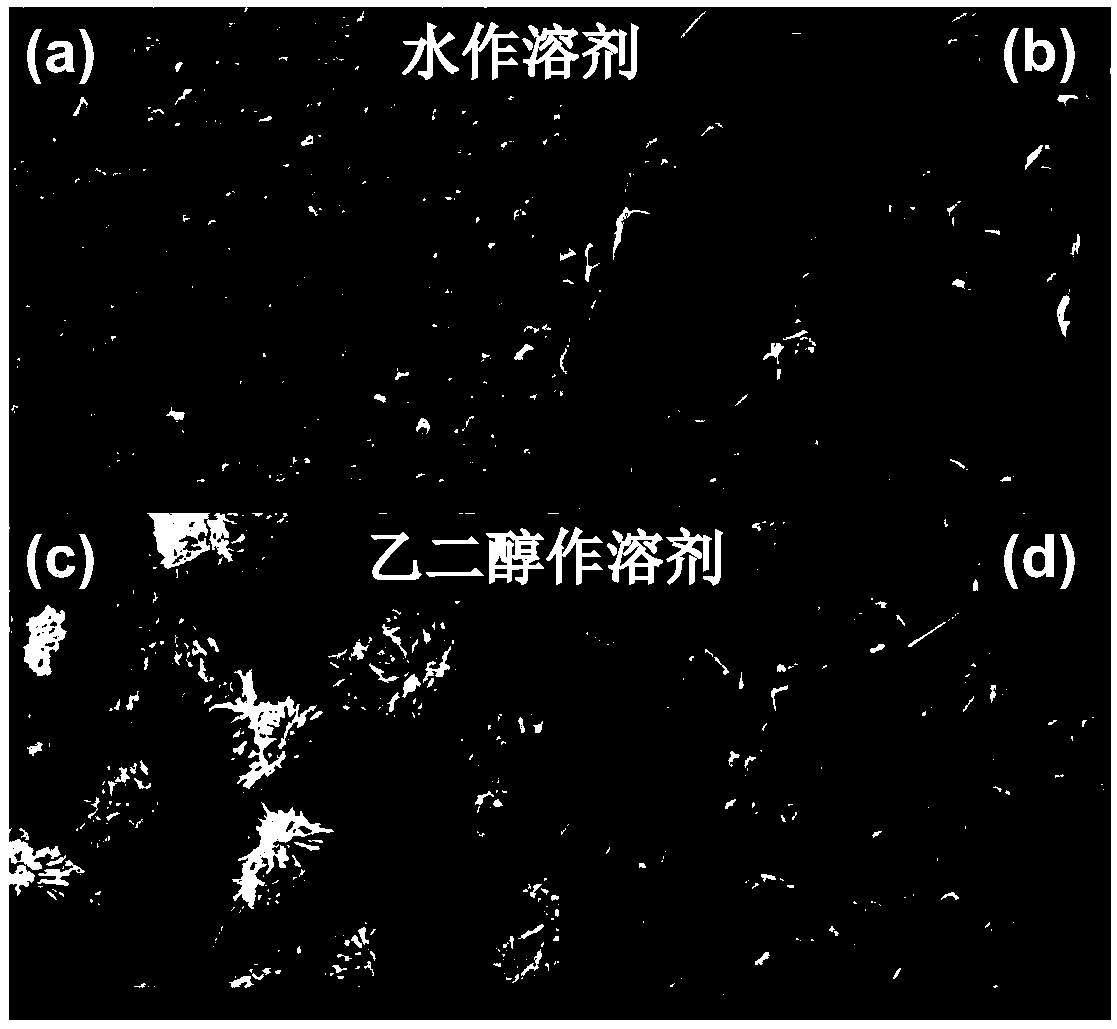

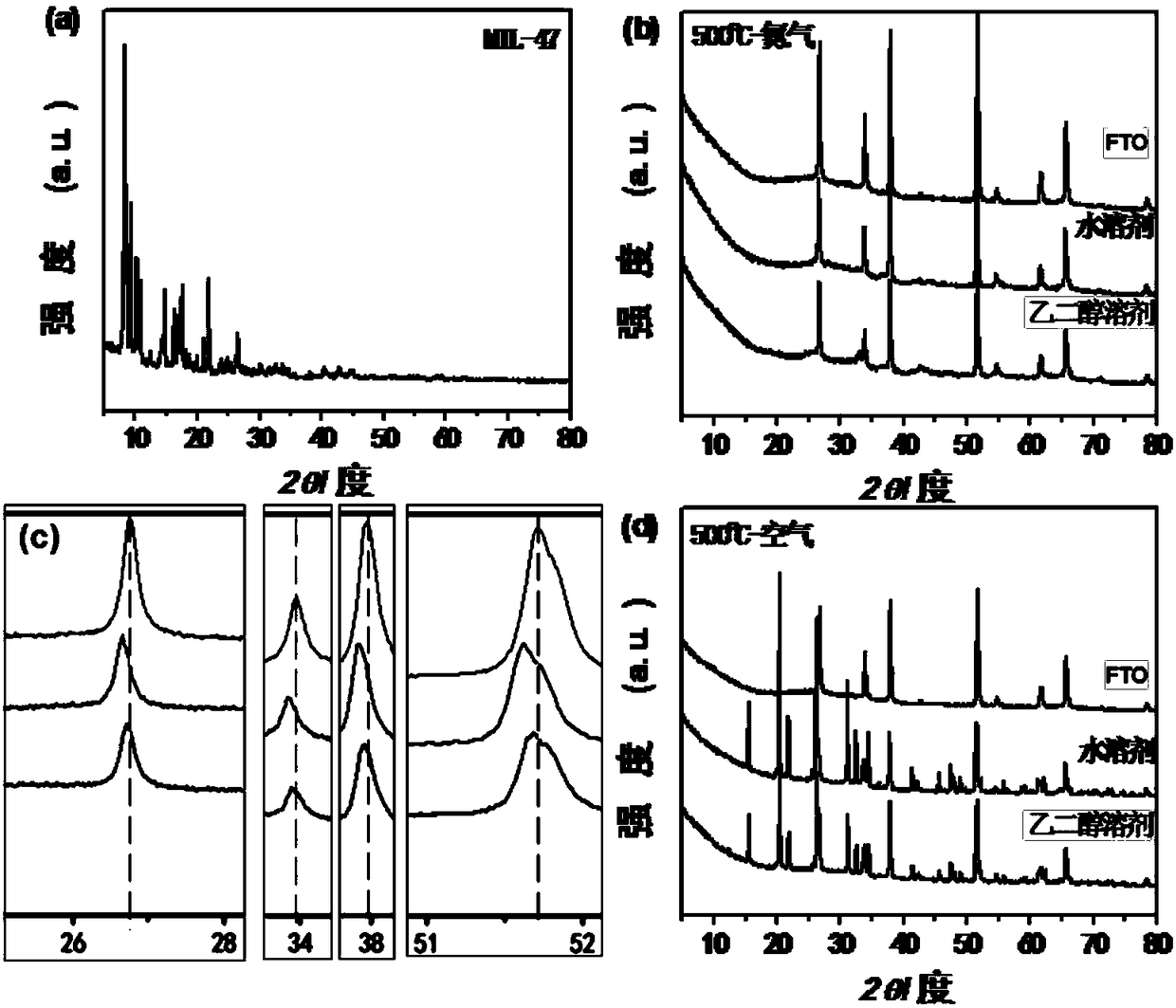

[0054] Example 1, a MIL-47 metal-organic framework material and its preparation method

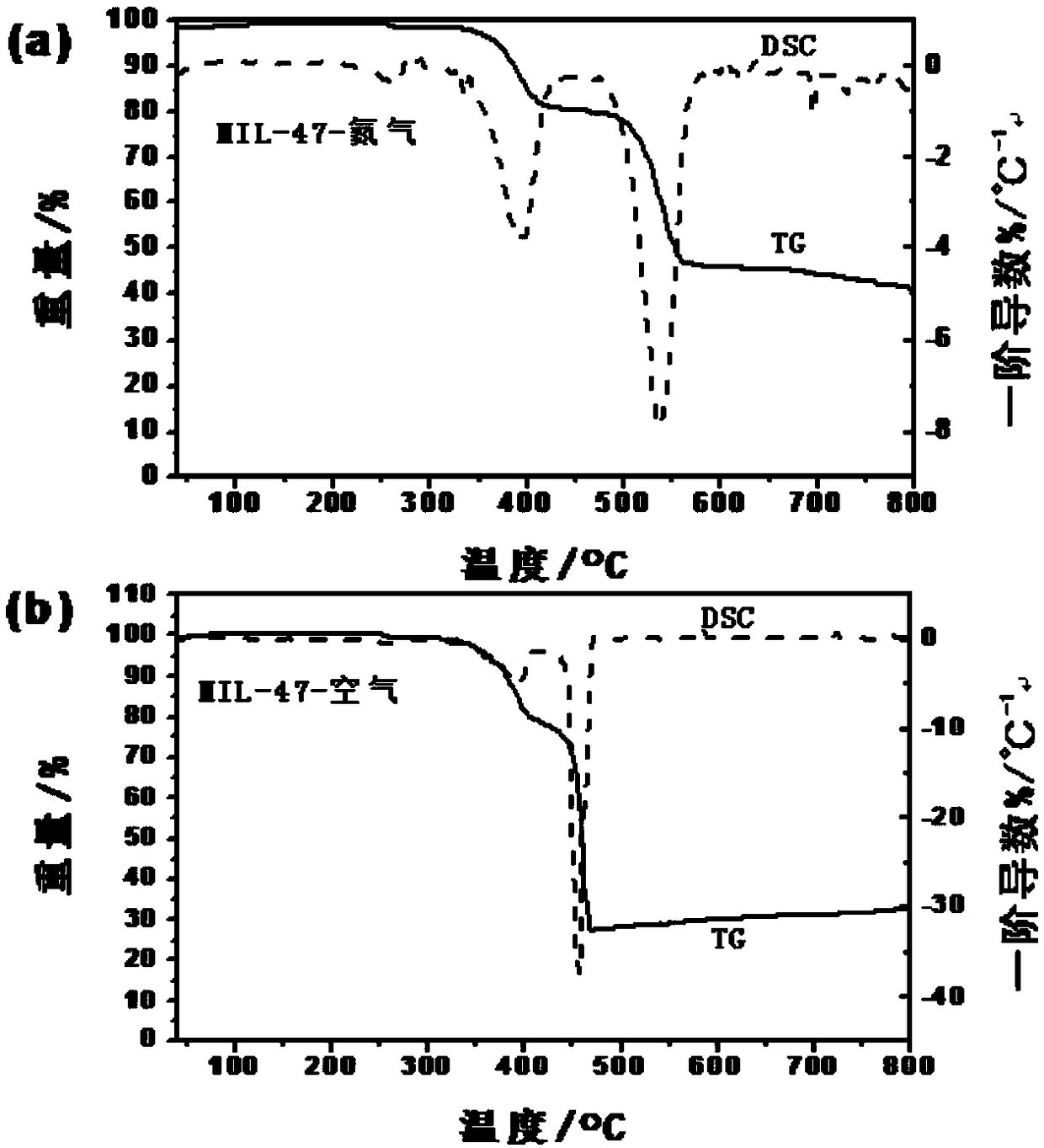

[0055] (1) Preparation of MIL-47 frame material, the preparation process is: respectively weigh 1.3g-1.6g of vanadium trichloride and 0.2g-0.4g of 1,4-phthalic acid; Put into 12g~15g deionized water solvent, and stir for 15~30min; transfer the stirred solution to a reaction kettle with polytetrafluoroethylene lining, keep it at 180~200℃ for 4~5 days, then cool to room temperature; (4) use vacuum filtration to remove the liquid, and then wash the obtained solid with 100-200 mL of acetone for 3-5 times to obtain a light green solid.

[0056] (2) Remove the guest molecule (i.e. free 1,4-phthalic acid ligand) in MIL-47. The operation steps are: roast the above-mentioned light green solid at 200-220°C for 1-2 hours, and then bake it at 250-220°C for 1-2 hours. Roasting at 400°C for 10-24 hours, the roasting apparatus is one of tube furnace or muffle furnace, and the MIL-47 metal-organic framew...

Embodiment 2

[0060] Example 2, a MIL-47 metal-organic framework material and its preparation method

[0061] Except that 13g of deionized water described in step (1) of Example 1 was replaced by 13g of ethylene glycol, other processes were consistent with those described in Example 1.

Embodiment 3

[0062] Example 3, a MIL-47 metal-organic framework material and its preparation method

[0063] Except that 13 g of deionized water described in step (1) of Example 1 was replaced with 13 g of ethanol, other processes were consistent with those described in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com