Image sensor and forming method thereof

An image sensor and ion implantation technology, which is used in the manufacture of electrical solid-state devices, semiconductor devices, and semiconductor/solid-state devices. The ability to store photoelectrons, the effect of increasing the full well capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

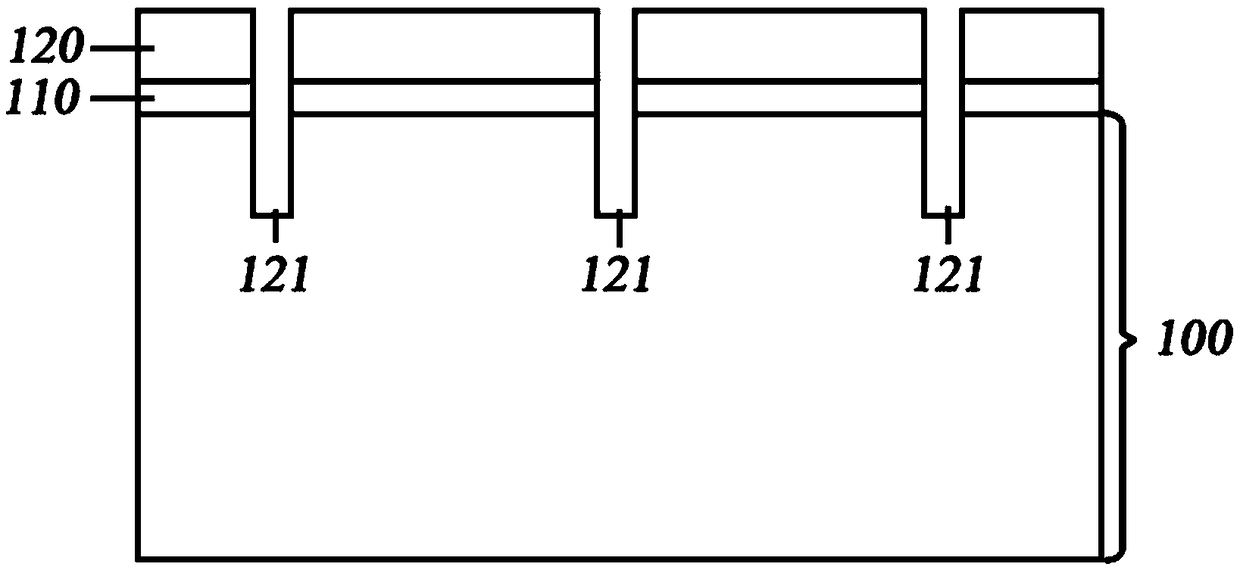

[0031] Figure 2-Figure 7 Provided is a method for forming a partial device layer structure of a back-illuminated CMOS image sensor.

[0032] refer to figure 2 , providing a semiconductor substrate 100 and forming a protection layer 110 covering the semiconductor substrate 100 .

[0033] In a specific implementation, the semiconductor substrate 100 may be a silicon substrate, or the material of the semiconductor substrate 100 may also be germanium, silicon germanium, silicon carbide, gallium arsenide, or gallium indium. The bottom 100 may also be a silicon substrate on an insulator surface or a germanium substrate on an insulator surface, or a substrate grown with an epitaxial layer (Epitaxy layer, Epi layer).

[0034] Preferably, the semiconductor substrate 100 is a lightly doped semiconductor substrate, and the doping type is opposite to that of the photodiodes formed in the semiconductor substrate 100 in subsequent processes. Specifically, deep well implantation (Deep W...

Embodiment 2

[0060] This embodiment is relatively close to Embodiment 1, but slightly different. The difference is that in this embodiment, after the buried layer 132 of the photodiode is formed through the first doping, the buried layer 132 is doped by using different ion implantation processes.

[0061] refer to Figure 9 , remove the second mask layer 130, re-form a third mask layer 140 on the protective layer 110, pattern the third mask layer 140, and expose the edge region 142 of the buried layer 132; In the third ion implantation process, a third doping is performed on the edge region 142 of the buried layer 132 .

[0062] The third doping uses the same type of doping ions as the first doping. In this embodiment, the doping ions used in the first ion implantation process are N-type ions As, and the third ions The dopant ions used in the implantation process are also As, and the energy is about 50-300 KeV higher than the ion energy used in the first ion implantation process. In thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com