Preparation method of corrosion-resistant super-hydrophobic aluminum surface

A super-hydrophobic, aluminum surface technology, applied in welding equipment, manufacturing tools, laser welding equipment, etc., can solve the problems of weak hydrophobic performance and corrosion resistance, high cost, and achieve good hydrophobic performance, short processing time, and easy availability of raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

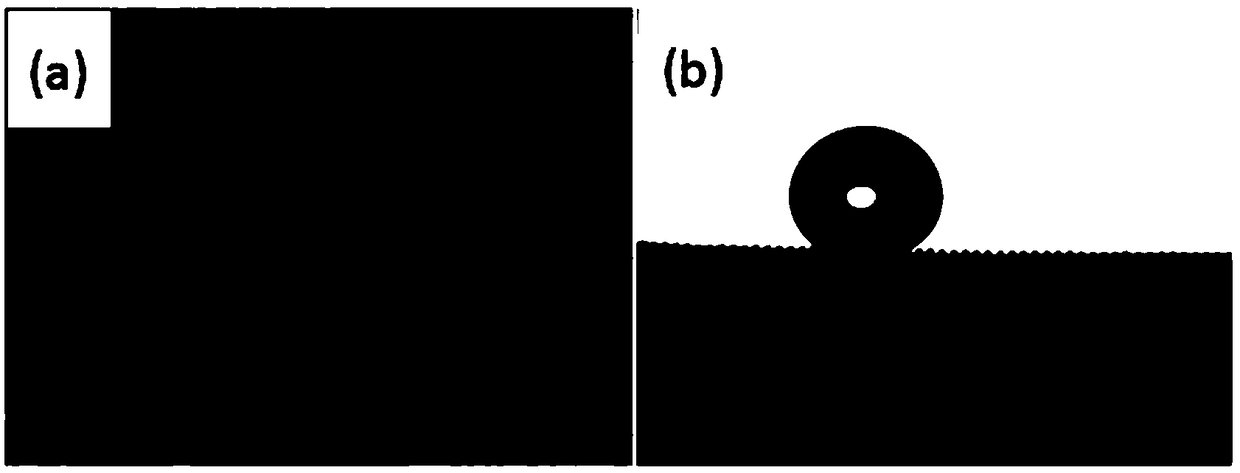

Embodiment 1

[0033] The preparation method of the superhydrophobic aluminum surface of the present embodiment, comprises the steps:

[0034] (1) Pretreatment: 1060 aluminum samples of 20mm×20mm×2mm were ultrasonically cleaned with anhydrous ethanol and distilled water in sequence, with a single cleaning time of 4min and a power of 36kHz, and dried in a constant temperature oven at 110°C for 15min to obtain clean aluminum slice sample;

[0035] (2) Infrared laser processing: use an infrared laser marking machine to etch the surface of the pretreated aluminum sheet sample. The process parameters of laser etching are as follows: the laser frequency is 20kHz, the maximum laser output power is 20W, and the laser wavelength is 1064nm. The speed is 50mm·s -1 , The scanning distance is 200μm, the single exposure time is 5ms, and the grating-like microstructure is etched;

[0036] (3) Reprocessing: Ultrasonic cleaning is performed on the processed samples using absolute ethanol and distilled wate...

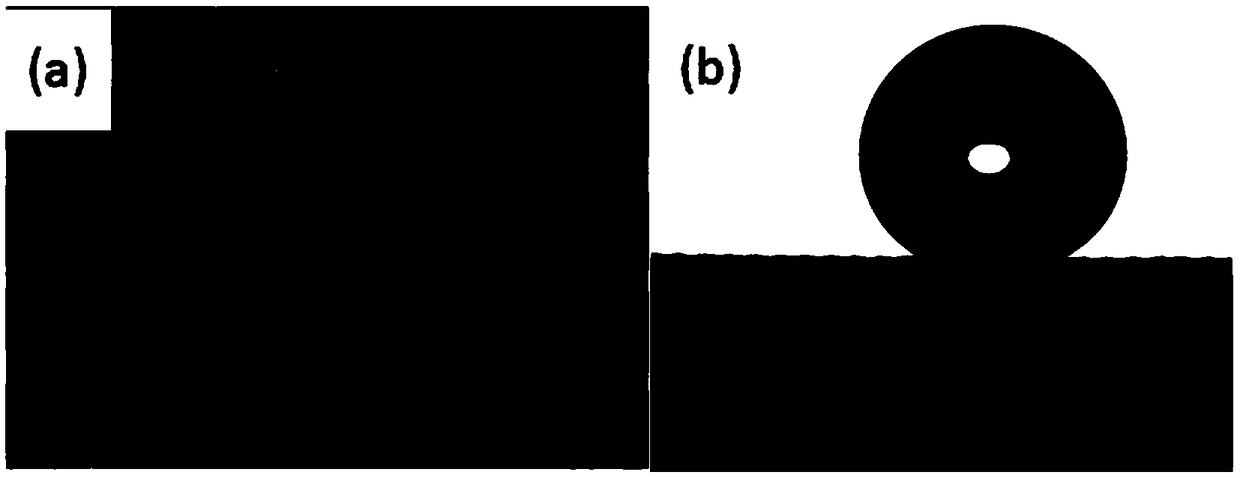

Embodiment 2

[0045] The preparation method of the superhydrophobic aluminum surface of the present embodiment, comprises the steps:

[0046] (1) Pretreatment: 1060 aluminum sheet samples of 20mm×20mm×2mm were ultrasonically cleaned with anhydrous ethanol and distilled water in sequence, once cleaned for 4min, with a power of 36kHz, and dried in a constant temperature oven at 110°C for 15min to obtain a clean Aluminum sheet samples;

[0047] (2) Infrared laser processing: use an infrared laser marking machine to etch the surface of the pretreated aluminum sheet sample. The process parameters of the laser etching are: the laser frequency is 20kHz, the maximum laser output power is 20W, and the laser wavelength is 1064nm. The speed is 50mm·s -1 , The scanning distance is 200μm, the single exposure time is 5ms, and the grating-like microstructure is etched;

[0048](3) Reprocessing: Ultrasonic cleaning is performed on the processed samples using absolute ethanol and distilled water in sequen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com