A radial reactor and a process method of chemical chain reaction

A process method and reactor technology applied in the field of radial reactors to achieve the effects of simple process flow, uniform distribution of raw material gas, and short service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

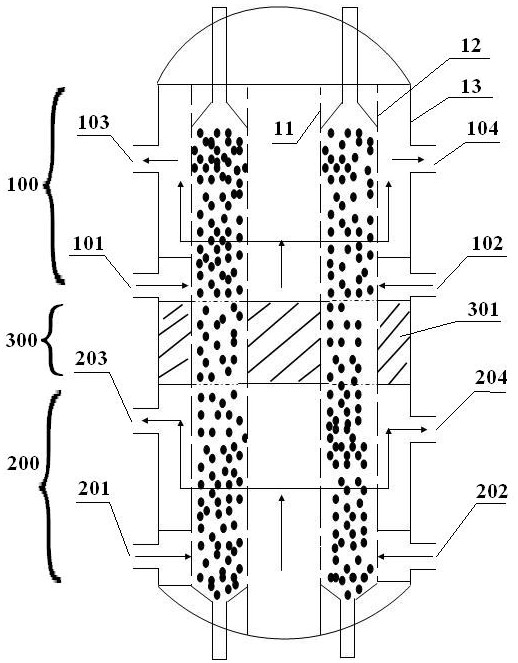

[0031] A radial reactor such as figure 1As shown, it includes three layers of inner cylinder 11, middle cylinder 12 and outer cylinder 13, several openings are uniformly distributed on the cylinder wall of the inner cylinder 11 and the middle cylinder 12, and the cylinder wall of the outer cylinder 13 is a closed entity; the reaction The device is divided into an upper reaction zone 100 and a lower reaction zone 200, and a closed zone 300 is set between the two reaction zones. The closed zone 300 is in the central space of the inner cylinder 11, and in the wall space of the middle cylinder 12 and the outer cylinder 13. There is a refractory brick filling section 301, two upper reaction zone inlets 101, 102 symmetrically distributed are arranged at the bottom of the upper reaction zone 100, and two upper reaction zone outlets 103, 104 symmetrically distributed are arranged at the top of the upper reaction zone 100; Yes, the lower reaction zone is also provided with lower reacti...

Embodiment 2

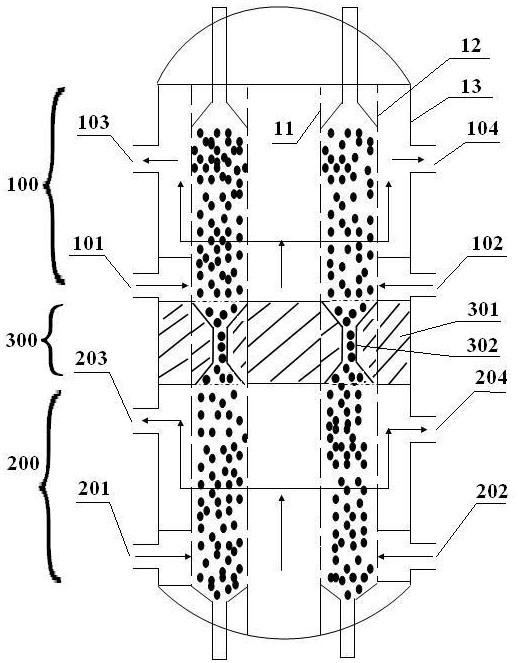

[0033] A radial reactor such as figure 2 As shown, it includes three layers of inner cylinder 11, middle cylinder 12 and outer cylinder 13, several openings are uniformly distributed on the cylinder wall of the inner cylinder 11 and the middle cylinder 12, and the cylinder wall of the outer cylinder 13 is a closed entity; the reaction The device is divided into an upper reaction zone 100 and a lower reaction zone 200, and a closed zone 300 is set between the two reaction zones. The closed zone 300 is in the central space of the inner cylinder 11, and in the wall space of the middle cylinder 12 and the outer cylinder 13. Each has a refractory brick filling section 301, a dumbbell-shaped buffer device 302 is provided between the inner cylinder and the middle cylinder corresponding to the closed area 300, and two upper reaction area inlets 101, 102 symmetrically distributed are arranged at the lower part of the upper reaction area 100 , the top of the upper reaction zone 100 is ...

Embodiment 3

[0035] A radial reactor such as figure 1 As shown, it includes three layers of inner cylinder 11, middle cylinder 12 and outer cylinder 13, several openings are uniformly distributed on the cylinder wall of the inner cylinder 11 and the middle cylinder 12, and the cylinder wall of the outer cylinder 13 is a closed entity; the reaction The device is divided into an upper reaction zone 100 and a lower reaction zone 200, and a closed zone 300 is set between the two reaction zones. The closed zone 300 is in the central space of the inner cylinder 11, and in the wall space of the middle cylinder 12 and the outer cylinder 13. There is a refractory brick filling section 301, two upper reaction zone inlets 101, 102 symmetrically distributed are arranged at the bottom of the upper reaction zone 100, and two upper reaction zone outlets 103, 104 symmetrically distributed are arranged at the top of the upper reaction zone 100; Yes, the lower reaction zone is also provided with lower react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com