Biomass carbon and preparation method and application thereof

A technology of biochar and biomass, applied in the direction of carbon preparation/purification, chemical instruments and methods, applications, etc., which can solve problems such as consumption, inability to improve soil, weak processing capacity and raw material adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

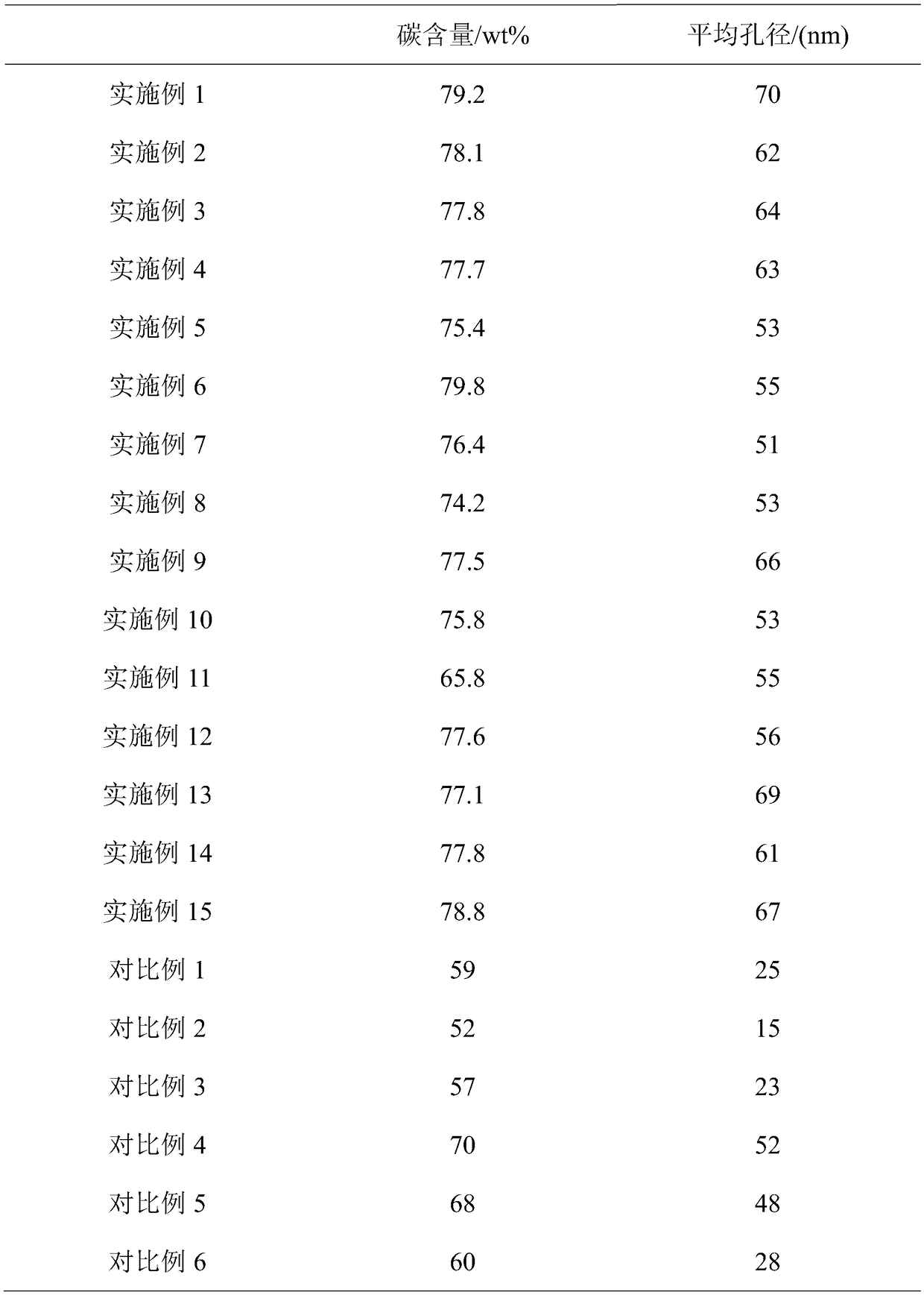

Examples

Embodiment 1

[0057] The present embodiment provides a preparation method of biomass charcoal, and the preparation method includes the following steps:

[0058] The biomass raw material used in the preparation method is rice straw;

[0059] (1) pulverize and handle biomass raw material, obtain the pulverized biomass raw material of length 0.2m;

[0060] (II) Preliminary thermal cracking treatment step (I) obtained pulverized biomass raw material, to obtain preliminary carbonized biomass, the heating rate of the preliminary thermal cracking treatment is 30 ° C / min, the temperature of the preliminary thermal cracking treatment is 200 ° C, the preliminary thermal cracking The incubation time of cracking treatment is 3min;

[0061] (III) Preliminary carbonized biomass described in step (II) deep thermal cracking treatment to obtain biomass char and undecomposed biomass raw materials, the heating rate of the deep thermal cracking treatment is 30°C / min, and the temperature of the deep thermal cr...

Embodiment 2

[0065] The present embodiment provides a preparation method of biomass charcoal, and the preparation method includes the following steps:

[0066] The biomass raw material used in the preparation method is corn stover;

[0067] (1) pulverize and handle biomass raw material, obtain the pulverized biomass raw material of length 0.3m;

[0068](II) Preliminary thermal cracking treatment step (I) obtained pulverized biomass raw material, to obtain preliminary carbonized biomass, the heating rate of the preliminary thermal cracking treatment is 20 ° C / min, the temperature of the preliminary thermal cracking treatment is 150 ° C, the preliminary thermal cracking The incubation time of cracking treatment is 2min;

[0069] (III) Preliminary carbonized biomass described in step (II) deep thermal cracking treatment to obtain biomass char and undecomposed biomass raw materials, the heating rate of the deep thermal cracking treatment is 15°C / min, and the temperature of the deep thermal cr...

Embodiment 3

[0073] The present embodiment provides a preparation method of biomass charcoal, and the preparation method includes the following steps:

[0074] The biomass raw material used in the preparation method is a mixture of tobacco straw and sorghum straw;

[0075] (1) pulverize and handle biomass raw material, obtain the pulverized biomass raw material of length 0.1m;

[0076] (II) Preliminary thermal cracking treatment step (I) obtained pulverized biomass raw material, to obtain preliminary carbonized biomass, the heating rate of the preliminary thermal cracking treatment is 10 ° C / min, the temperature of the preliminary thermal cracking treatment is 300 ° C, the preliminary thermal cracking The incubation time of cracking treatment is 5min;

[0077] (III) Preliminary carbonized biomass described in step (II) of deep thermal cracking treatment to obtain biomass char and undecomposed biomass raw materials, the heating rate of the deep thermal cracking treatment is 60°C / min, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com