Zirconia ceramic powder and preparation method thereof

A zirconia ceramic and zirconia technology, which is applied in the field of multi-stabilizer zirconia ceramic powder and its preparation, can solve the problem of difficulty in manufacturing dense sintering, and achieve suitable mass production, wide solid solution range, and improved stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

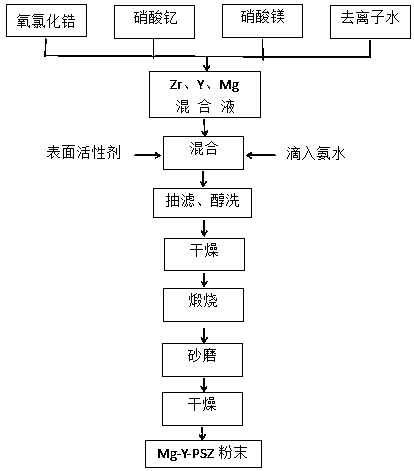

Method used

Image

Examples

Embodiment 1

[0028] A kind of preparation method of zirconia ceramic powder, with yttrium nitrate hexahydrate Y (NO 3 ) 3 ·6H 2 O, 97mol of zirconium oxychloride octahydrate ZrOCl 2 ·8H 2 O was added to deionized water, and yttrium-stabilized zirconia Y-TZP powder was prepared by co-precipitation method. After forming, sintering, polishing and other processes, 1.5mm zirconia grinding balls are made. Wherein, the sintering temperature is 1500-1530°C.

[0029] Then test the physical properties of the zirconia balls as follows (abrasion test conditions: bedroom test sand mill 1L, continuous test for 7 days, test temperature 60°C):

[0030] Density; 6.06g / cm 3

[0031] Average compressive crushing strength: 700Mpa.

[0032] Abrasion: 80ppm.

Embodiment 2

[0034] A kind of preparation method of zirconia ceramic powder, with the magnesium nitrate Mg of 2mol (NO 3 ) 2 ·6H 2 O, 3mol of Y (NO 3 ) 3 ·6H 2 O, 95mol of ZrOCl 2· ·8H 2 O was added to deionized water, and Mg and Y co-stabilized zirconia Y-Mg-PSZ powder was prepared by co-precipitation method. After forming, sintering, polishing and other processes, 1.5mm zirconia grinding balls are made. Then test the physical properties of the zirconia balls as follows (abrasion test conditions: bedroom test sand mill 1L, continuous test for 7 days, test temperature 60°C):

[0035] The best sintering temperature: 1490-1530℃.

[0036] Density; 6.02g / cm 3

[0037] Average compressive crushing strength: 615Mpa.

[0038] Abrasion: 135ppm.

Embodiment 3

[0040] A kind of preparation method of zirconia ceramic powder, with 1mol of Mg (NO 3 ) 2 ·6H 2 O, 3mol of Y (NO 3 ) 3 ·6H 2 O, 96mol of ZrOCl 2· ·8H 2 O was added to deionized water, and the co-stabilized zirconia powder was prepared by co-precipitation method. After forming, sintering, polishing and other processes, 1.5mm zirconia grinding balls are made. Then test the physical properties of the zirconia balls as follows (abrasion test conditions: bedroom test sand mill 1L, continuous test for 7 days, test temperature 60°C):

[0041] The best sintering temperature: 1460-1500℃.

[0042] Density; 6.07g / cm 3

[0043] Average compressive crushing strength: 685Mpa.

[0044] Abrasion: 70ppm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com