Anion-cation co-doped nickel-manganese-based material and application in sodium-ion battery positive electrode

An anion-cation and co-doping technology, applied in the field of material chemistry, can solve the problems of unfavorable industrial production, poor process stability, and high cost, and achieve the effects of improving cycle stability, low cost, and reducing phase transition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

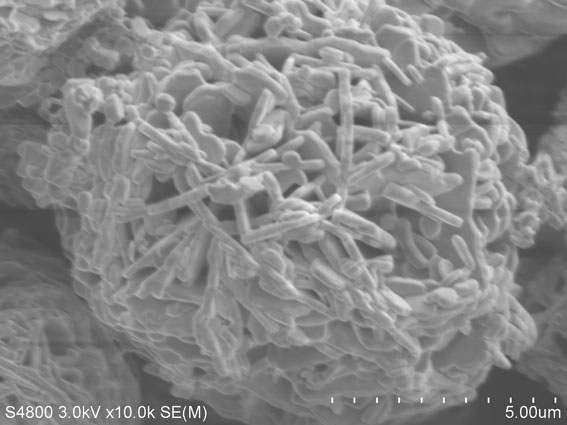

[0035] A preparation method of an anion-cation co-doped nickel-manganese-based material, comprising the following steps:

[0036] Step 1, configuration containing ammonia and NH 4 Mixed solution A of F, wherein the ammonia concentration is 1mol / L, NH 4 F concentration is 0.02mol / L;

[0037] Configure a mixed solution B containing nickel salt (nickel sulfate) and manganese salt (manganese sulfate), wherein the molar ratio of nickel sulfate and manganese sulfate is 0.25:0.75, and the total concentration of nickel sulfate and manganese sulfate is 4mol / L;

[0038] Configure the mixed solution C containing template agent and strong base: template agent selects methyl cellulose, strong base selects sodium hydroxide, and the methyl cellulose of 0.5wt% is dissolved in the sodium hydroxide solution that concentration is 2mol / L, A mixed solution C was obtained.

[0039]Step 2, configure the ammonia water with a concentration of 0.1 mol / L, adjust the pH value to 11.8 by using the mixe...

Embodiment 2

[0044] Compared with Example 1, only the weight of methyl cellulose in mixed solution C was changed to 2wt%, and other conditions remained unchanged.

Embodiment 3

[0046] Compared with Example 1, only the weight of methylcellulose in mixed solution C was changed to 0.1 wt%, and other conditions remained unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com