A method for preparing α-tricalcium phosphate based on inositol molecule and its application

A technology of tricalcium phosphate and amorphous calcium phosphate, which is applied in the fields of materials science and biomedicine, can solve problems affecting product effects, and achieve the effects of shortening the preparation cycle, reducing energy consumption, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] 1) Accurately prepare 0.4mol / L Ca(NO 3 ) 2 Solution 200ml (solution A), and 0.266mol / L (NH 4 ) 2 HPO 4 Solution 200ml (Solution B).

[0060] 2) Add 2 g of inositol to solution A under 28°C water heating and magnetic stirring, stir for 30 minutes to obtain a uniform solution, then add ammonia water dropwise to raise the pH to 10.2-10.5, and then use a separatory funnel to dissolve Solution B was added dropwise to solution A, and the pH of the mixture was kept between 10.2 and 10.5 during the process. The dropwise addition was completed after 40 minutes, and stirring was continued for 30 minutes.

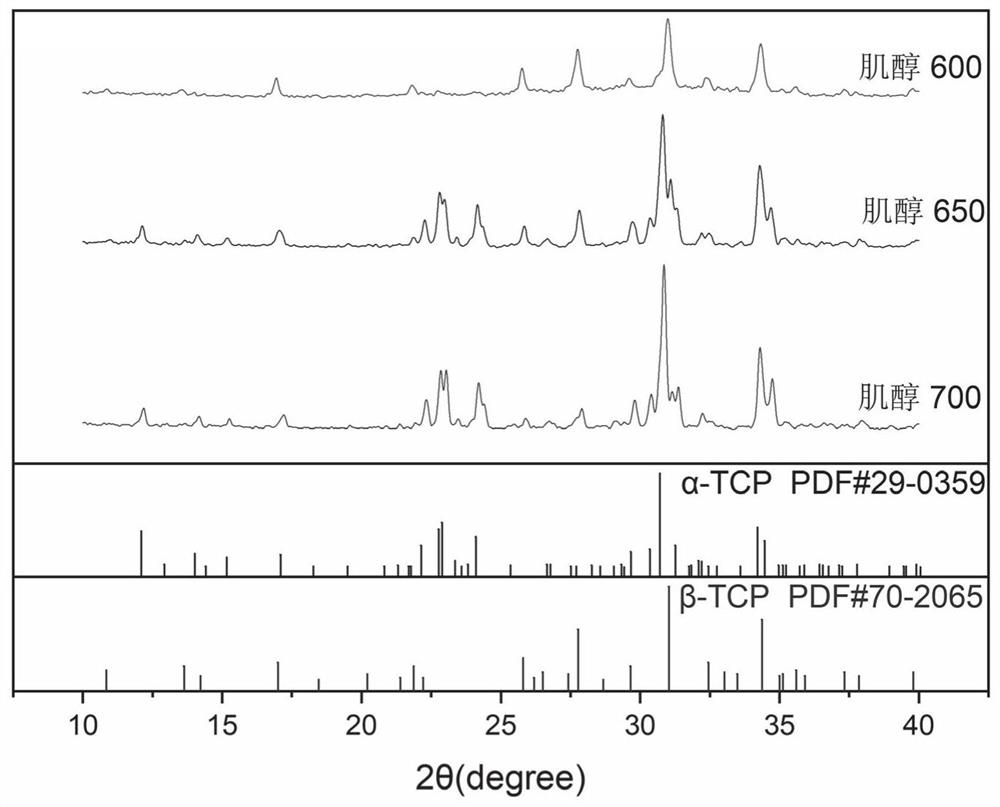

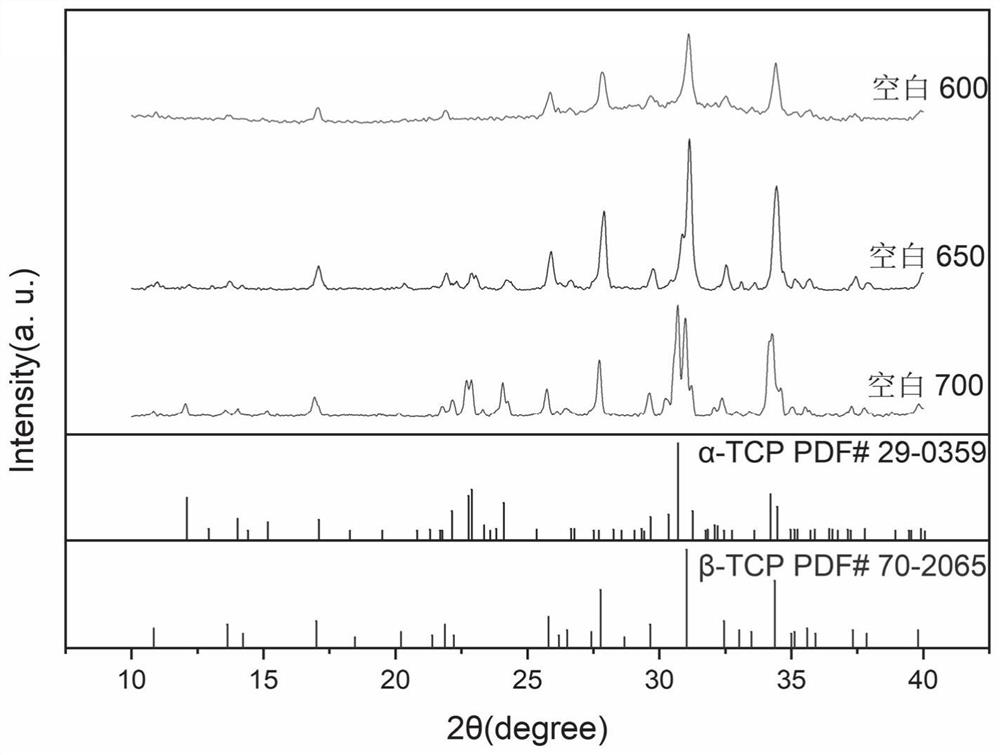

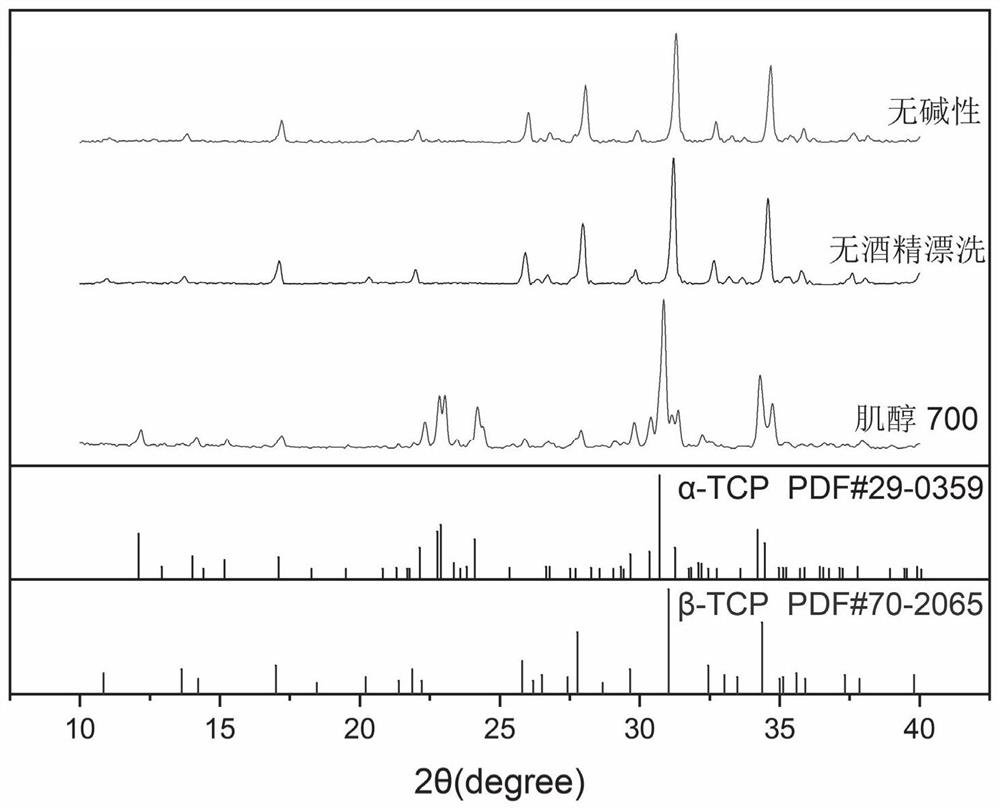

[0061] 3) Suction filter the above solution, wash the original solution three times with water and absolute ethanol after the suction filtration, then air-dry at room temperature (28°C) for 6 to 8 hours, then coarsely grind the dried particles in a mortar, and then Carry out calcination, the calcination treatment conditions are: heating rate 10°C / min, calcination temperat...

Embodiment 2

[0064] 1) Accurately prepare 0.4mol / L Ca(NO 3 ) 2 Solution 200ml (solution A), and 0.266mol / L (NH 4 ) 2 HPO 4 Solution 200ml (Solution B).

[0065] 2) Add 2 g of inositol to solution A under 28°C water heating and magnetic stirring, stir for 30 minutes to obtain a uniform solution, then add ammonia water dropwise to raise the pH to 10.2-10.5, and then use a separatory funnel to dissolve Solution B was added dropwise to solution A, and the pH of the mixture was kept between 10.2 and 10.5 during the process. The dropwise addition was completed after 40 minutes, and stirring was continued for 30 minutes.

[0066] 3) Suction filter the above solution, wash the original solution three times with water and absolute ethanol after the suction filtration, then air-dry at room temperature (28°C) for 6 to 8 hours, then coarsely grind the dried particles in a mortar, and then Carry out calcination, and the calcination treatment conditions are: heating rate 10°C / min, calcination temp...

Embodiment 3

[0069] 1) Accurately prepare 0.4mol / L Ca(NO 3 ) 2 Solution 200ml (solution A), and 0.266mol / L (NH 4 ) 2 HPO 4 Solution 200ml (Solution N).

[0070] 2) Add 2 g of inositol to solution A under 28°C water heating and magnetic stirring, stir for 30 minutes to obtain a uniform solution, then add ammonia water dropwise to raise the pH to 10.2-10.5, and then use a separatory funnel to dissolve Solution B was added dropwise to solution A, and the pH of the mixture was kept between 10.2 and 10.5 during the process. The dropwise addition was completed after 40 minutes, and stirring was continued for 30 minutes.

[0071] 3) Suction filter the above solution, wash the original solution three times with water and absolute ethanol after the suction filtration, then air-dry at room temperature (28°C) for 6 to 8 hours, then coarsely grind the dried particles in a mortar, and then Carry out calcination, the calcination treatment conditions are: heating rate 10°C / min, calcination temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com