Preparation method of modified natural chitin bio-based high-performance polycarboxylate water reducer

The technology of chitin and polycarboxylic acid is applied in the field of preparation of modified natural chitin bio-based high-performance polycarboxylate water reducing agent, which can solve the problems of single function, environmental pollution and high price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

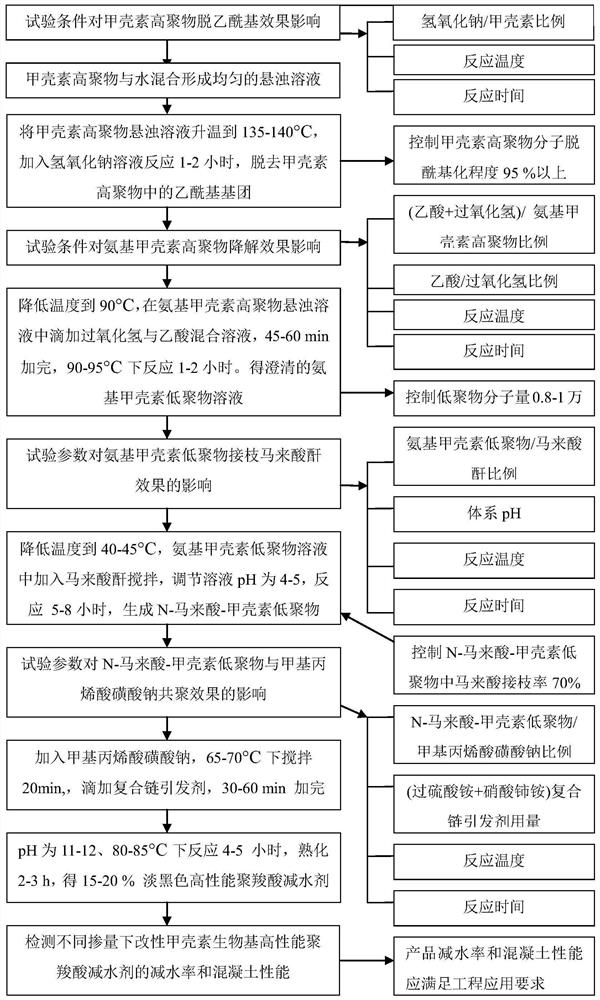

Method used

Image

Examples

Embodiment 1

[0041] 1. Preparation of modified natural chitin bio-based high-performance polycarboxylate superplasticizer

[0042] 1.1. Preparation of amino chitin polymer

[0043] The chitin high polymer (weight average molecular weight: 335,400) of Nantong Langshan Xingcheng Biochemical Products Factory was used as a raw material. Weigh 300kg of chitin polymer and 700kg of water into a reaction vessel equipped with a stirrer, a thermometer, a dropping funnel, and a reflux condenser. Raise the temperature to 80°C and stir to form a uniform suspension solution. Raise the temperature to 138°C, add 1170kg of sodium hydroxide solution (50% by weight) to the chitin high polymer suspension solution for deacetylation, stir at 138°C for 1.5 hours, and generate carapace containing amino groups Chitin high polymer (concentration is 20-25%), control the degree of deacylation in the chitin high polymer molecule to more than 95%.

[0044] 1.2. Degradation of chitin polymer

[0045] Lower the tempe...

Embodiment 2

[0051] 2. Preparation of modified natural chitin bio-based high-performance polycarboxylate superplasticizer

[0052] 2.1. Preparation of aminochitin polymer

[0053] The chitin high polymer (weight average molecular weight: 335,400) of Nantong Langshan Xingcheng Biochemical Products Factory was used as a raw material. Weigh 330kg of chitin polymer and 670kg of water into a reaction vessel equipped with a stirrer, a thermometer, a dropping funnel, and a reflux condenser. Raise the temperature to 80°C and stir to form a uniform suspension solution. Raise the temperature to 138°C, add 1185kg of sodium hydroxide solution (50% by weight) to the chitin high polymer suspension solution for deacetylation treatment, stir at 135°C for 2 hours, and generate carapace containing amino groups Chitin high polymer (concentration is 20-25%), control the degree of deacylation in the chitin high polymer molecule to more than 95%.

[0054] 2.2. Degradation of chitin polymer

[0055] Lower th...

Embodiment 3

[0061] 3. Preparation of modified natural chitin bio-based high-performance polycarboxylate superplasticizer

[0062] 3.1. Preparation of aminochitin polymer

[0063] The chitin high polymer (weight average molecular weight: 335,400) of Nantong Langshan Xingcheng Biochemical Products Factory was used as a raw material. Weigh 350kg of chitin polymer and 660kg of water into a reaction vessel equipped with a stirrer, a thermometer, a dropping funnel, and a reflux condenser. Raise the temperature to 80°C and stir to form a uniform suspension solution. Raise the temperature to 1140°C, add 1200kg of sodium hydroxide solution (50% by weight) to the chitin high polymer suspension solution for deacetylation treatment, stir at 140°C for 1 hour, and generate carapace containing amino groups Chitin high polymer (concentration is 20-25%), control the degree of deacylation in the chitin high polymer molecule to more than 95%.

[0064] 3.2. Degradation of chitin polymer

[0065]Lower the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| sand rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com