Integrated resistive memory and a preparation method thereof

A technology of resistive variable memory and resistive variable layer, which is applied in the direction of electrical components, etc., can solve the problems of complex manufacturing process, inability to adapt to the development trend of integrated resistive variable memory, and high manufacturing cost, so as to improve storage density, facilitate large-scale manufacturing, The effect of increasing storage density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

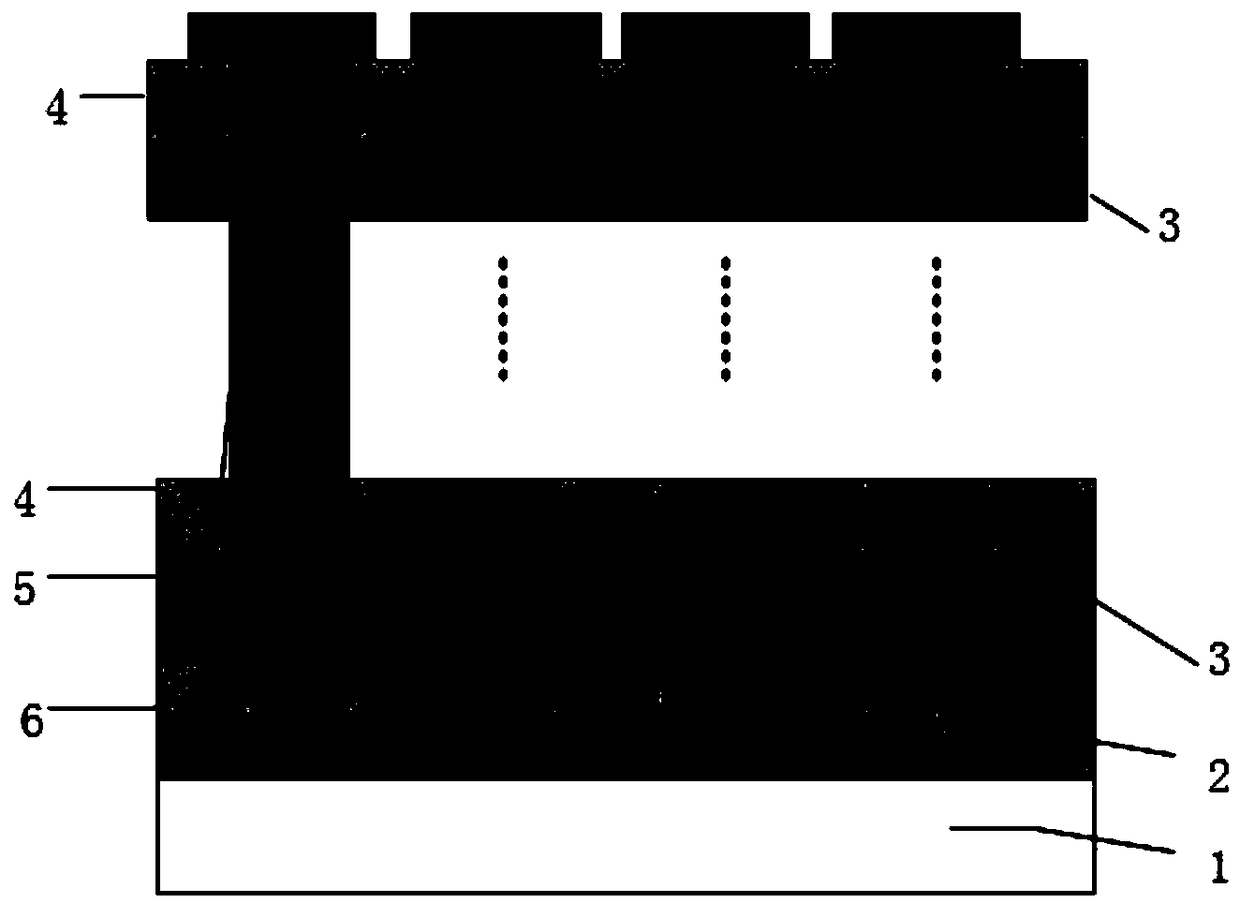

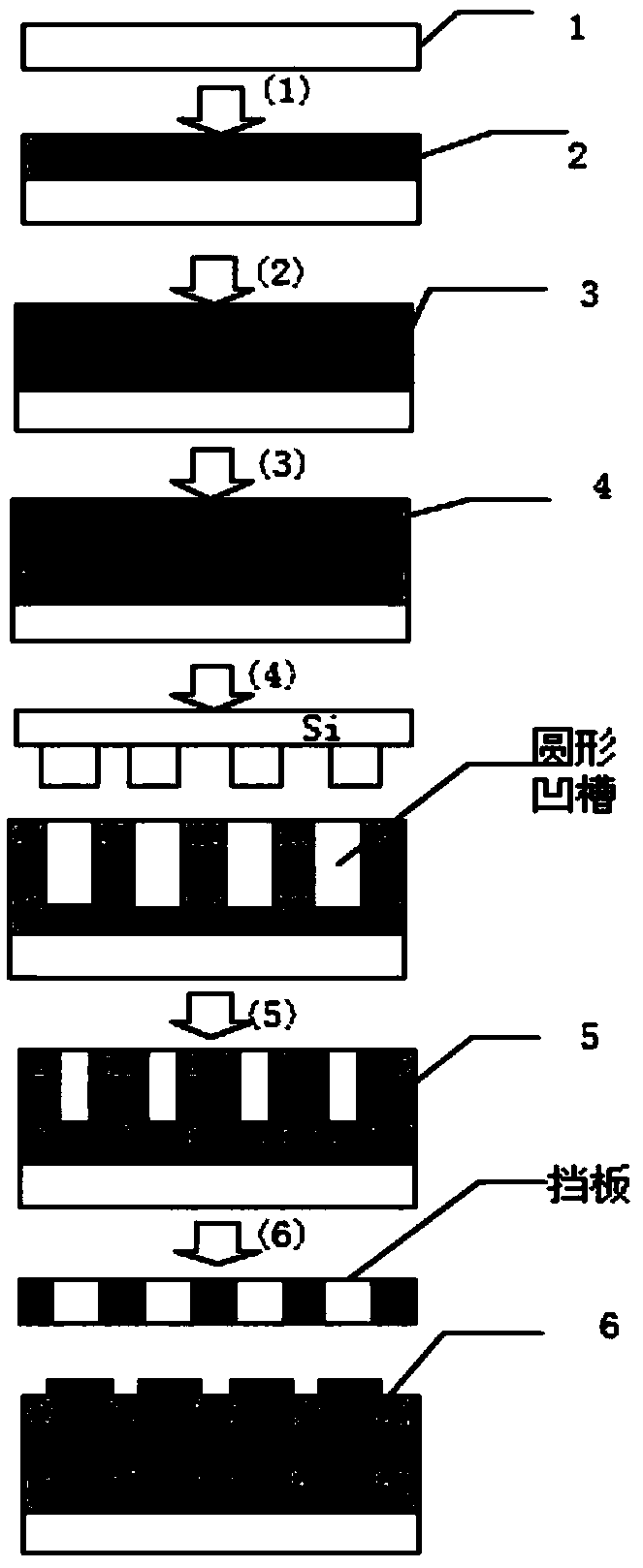

[0042] Please refer to image 3, a method for preparing an integrated resistive memory of the present invention, comprising the following steps:

[0043] Step 1, apply the liquid PMMA embossing adhesive material on the surface of the non-conductive substrate 1 by centrifugal glue spreading, glue spraying or screen printing, and evenly distribute the embossing layer 2 on the surface of the substrate 1;

[0044] Step 2, using a magnetron sputtering process to sputter-deposit the surface of the PMMA imprinting glue on the silicon wafer substrate 1 to form a bottom electrode layer 3 structure of a conductive metal;

[0045] Step 3, apply the liquid PMMA embossing adhesive material to the surface of the conductive metal bottom electrode layer by centrifugal glue laying, glue spraying or screen printing, and evenly distribute the isolation layer 4 on the surface; the thickness of the bottom electrode layer 3 is about 100nm;

[0046] Step 4, using a three-layer composite thermal em...

Embodiment 1

[0051] A method for preparing a single-layer integrated resistive variable memory of the present invention comprises the following steps:

[0052] (1) Apply the liquid embossing adhesive material on the surface of the silicon dioxide insulating layer by centrifugal glue laying, glue spraying or screen printing, and evenly distribute the embossing layer 2 on the surface of the silicon dioxide insulating layer.

[0053] (2) Using a magnetron sputtering process, sputtering deposits the embossing glue on the silicon wafer substrate to form a layer of conductive metal as the bottom electrode layer 3 .

[0054] (3) Apply the liquid PMMA embossing adhesive material to the surface of the conductive metal bottom electrode layer structure 3 by centrifugal glue laying, glue spraying or screen printing, and evenly distribute the isolation layer 4 on the bottom electrode layer structure 3; The thickness of the metal bottom electrode layer is about 100 nm.

[0055] (4) Using a three-layer ...

Embodiment 2

[0059] A method for preparing a multi-layer integrated resistive variable memory of the present invention, the preparation method is based on Example 1, and steps 2 and 3 can be repeated for the required number of layers; the metal bottom electrode layer and the metal bottom electrode layer are repeatedly stacked on the isolation layer. The isolation layer can form 1-100 multi-layer RRAM on the substrate at one time to obtain a multi-layer integrated resistive variable memory.

[0060] An integrated resistance variable memory (RRAM) preparation method of the present invention adopts a three-layer composite thermal embossing technology, and can be extended to manufacture multi-layer and integrated RRAM. The single-layer RRAM structure mainly includes a substrate, an embossing layer, a bottom electrode layer, an isolation layer, a resistive switch layer, and a top electrode layer; the material of the substrate is silicon dioxide or glass; the material of the embossing layer and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com