preparation method of nanometer Fe2O3/CoS-AC negative electrode material

A negative electrode material, fe2o3 technology, which is applied in the field of preparation of negative electrode materials for lithium ion batteries, can solve the problems of poor cycle performance, low battery specific capacity, etc., and achieves the effects of low discharge platform, simple preparation process and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

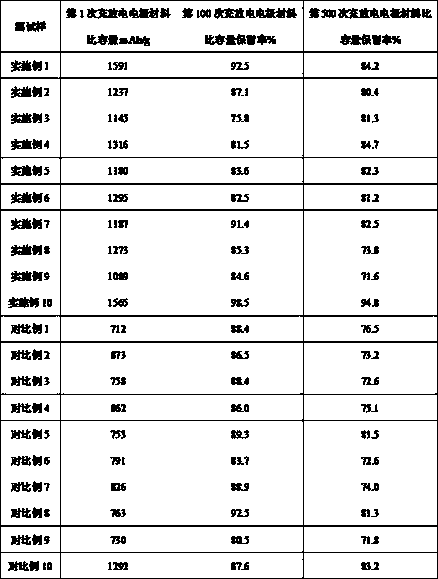

Examples

Embodiment 1

[0011] 1) Add 48 parts by weight of cobalt nitrate hexahydrate, 200 parts by weight of 75% ethanol solution, and 2 parts by weight of activated carbon into a four-necked flask equipped with a stirrer, a condenser and a thermometer, and stir magnetically for 30 minutes at 150rmp. Add 1 part by weight of thiourea, 14 parts by weight of Fe 3 o 4 / SiO 2 / NiO 2 Composite materials, ultrasonically disperse the mixture for 30min, transfer the solution to a polytetrafluoroethylene reactor at 160°C for 24h, then cool naturally to room temperature, and use 200 parts by weight of absolute ethanol and 200 parts by weight of deionized water to react the liquid Wash and dry in a vacuum oven at 60°C for 12 h to prepare a black powder for later use;

[0012] 2) Weigh 50 parts by weight of the above black powder, fully mix with 2 parts by weight of NaOH, 20 parts by weight of absolute ethanol, and 18 parts by weight of oleic acid, stir at 60°C for 2 hours, and slowly add 1 part by weight of...

Embodiment 2

[0016] Exactly the same as Example 1, the difference is: add 54 parts by weight of cobalt nitrate hexahydrate and 10 parts by weight of Fe 3 o 4 / SiO 2 / NiO 2 composite material.

Embodiment 3

[0018] Exactly the same as Example 1, the difference is: add 42 parts by weight of cobalt nitrate hexahydrate and 18 parts by weight of Fe 3 o 4 / SiO 2 / NiO 2 composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com