A kind of porous silicon carbon composite material and its preparation method and application

A technology of carbon composite materials and porous silicon, applied in the direction of electrical components, electrochemical generators, battery electrodes, etc., can solve the problem of low initial capacity, achieve high production efficiency, high capacity, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

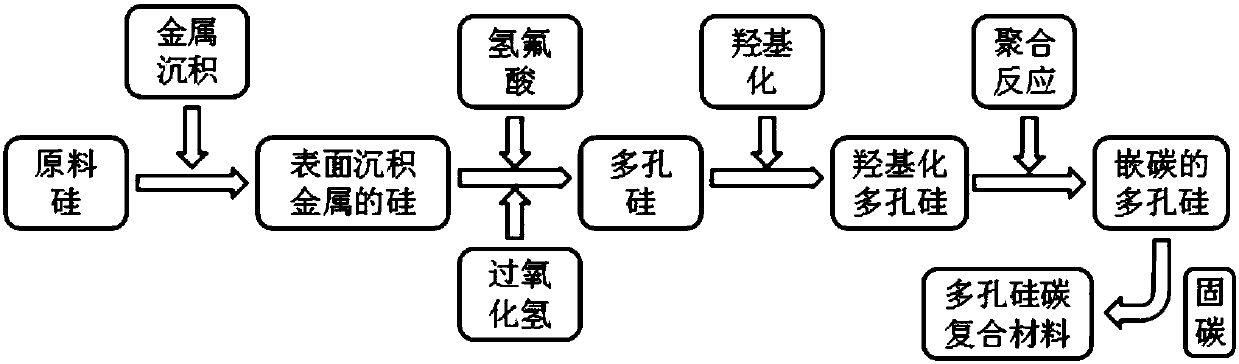

[0033] Elemental silicon (325mesh silicon powder), silver nitrate, sodium nitrite and p-phenylenediamine used in the preparation method of this embodiment are all analytically pure. The synthetic route of the product is as follows figure 1 shown. Concrete synthetic steps are as follows:

[0034] (1) Weigh 0.05 mmol of silver nitrate and dissolve it in 100 mL of deionized water, then add ammonia water dropwise to adjust the pH of the solution to 9.3. Add 1.0 g of silicon powder into the above solution, and disperse ultrasonically for 5 minutes until the silicon powder is evenly dispersed in the solution, and then magnetically stir at room temperature for 2 hours. Prepare 10 mL of glucose solution (0.045M) and add it dropwise to the previous solution. Continue to stir at room temperature for 12 hours, then vacuum filter and wash with deionized water, and dry in vacuum at 60° C. for 6 hours to obtain silicon powder with transition metal particles deposited on the surface.

[...

Embodiment 2

[0038] The elemental silicon used in the preparation method of this embodiment is calcined at high temperature by SiO to generate Si and SiO 2 The specific preparation steps are as follows: First, weigh 6.0g of SiO and heat it to 950°C in an Ar atmosphere, keep it warm for 5 hours, and maintain the heating rate at 5°C / min. The sintered product was taken out and immersed in 100 mL of 10 wt% HF solution and stirred magnetically at room temperature for 3 hours to remove SiO 2 , washed with water, filtered and dried in vacuum. Formulated with H 2 o 2 :H 2 SO 4 :H 2 The solution of O=1:1:3 is used to carry out hydroxylation treatment on the obtained product to increase the hydrophilic group and improve the solubility, and then wash with deionized water and filter and dry to obtain the elemental silicon raw material. The silver nitrate, sodium nitrite and p-phenylenediamine used were of analytical grade. The synthetic route of the product is as follows figure 1 shown. Concr...

Embodiment 3

[0043] The elemental silicon used in the preparation method of this example is extracted from agricultural waste rice husk, and the specific preparation steps are as follows: first, take 6 g of rice husk raw material, ultrasonically clean it with deionized water for 30 minutes, and then soak it in dilute hydrochloric acid solution Wash (100 mL, 20% by volume) for 6 hours, rinse with deionized water to pH=7 and dry. Put the above treated rice husk into a muffle furnace and sinter at 600 °C to fully remove the organic matter in it to obtain SiO 2 . Take 1g of SiO prepared above 2 Mix evenly with magnesium powder at a mass ratio of 1:2, and perform magnesium thermal reduction reaction at 650°C. Take out the black powder and immerse it in hydrochloric acid solution for 6 hours, then wash it with deionized water, and dry it to obtain the raw silicon powder. The silver nitrate, sodium nitrite and p-phenylenediamine used were of analytical grade. The synthetic route of the produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com